Developing fire-resistant resins for composites

Ashland, Polynt-Reichhold and Scott Bader discuss chemistries, applications and future developments for FR composites.

This blog is a follow-up to my February feature “Withstanding fire without the weight”. In my interviews for that article, three different resin suppliers/brands were mentioned: Ashland, Polynt and Scott Bader. I decided to follow up with these three companies to learn more.

Products

Ashland’s most prominent resin for FR composites is MODAR, which stands for MODified Acrylic Resin. It is non-halogenated, but Ashland also offers Hetron halogenated polyester or vinylester products.

Scott Bader’s Crestapol 1212 is a urethane acrylate, also non-halogenated, “which plays in the same sandbox as Modar,” according to Jean-Pascal (JP) Schroeder, technical director for adhesives and composites Scott Bader North America. Crystic polyester resins are also available, in halogenated or halogen-free formulations.

The Polynt-Reichhold Group combines four legacy resin manufacturers: PCCR, CCP, Polynt and Reichhold. The two main products for FR composites are DION brominated (the element bromine/Br is a halogen) resin technology from Reichhold and NORSODYNE laminating resin/FIREBLOCK gelcoat based on intumescent technology developed by CCP.

Halogen chemistry is head and shoulders above everything else … but cannot pass smoke and toxicity requirements.

Halogen vs. Non-halogen

“Halogen chemistry is head and shoulders above everything else,” says Thom Johnson, Ashland business manager for specialty resins. “The performance metric for being equivalent to brominated resins is really tough to beat.” He explains that bromine (Br) as a resin additive is very effective but also low in molecular weight, so it can leach out in a landfill. Many bromine additives have high toxicity, however, and are no longer allowed. “But there are others that have low toxicity and work well,” notes Johnson.

The alternative is to graft Br onto the backbone of the resin, producing a brominated resin, which has a high molecular weight. “Thus, it is insoluble in water and will not leach out,” Johnson notes. “It also eliminates metabolic concerns and cannot migrate away from the composite component, so there is no toxicity associated with the final parts.” This brominated resin chemistry is what Ashland offers via its Hetron products. “We have six or more products that we offer into a variety of industries where we are looking to meet FR only, not smoke,” says Johnson.

Not smoke? “Brominated resins cannot pass smoke and toxicity requirements,” explains Rick Pauer, applications development manager for Polynt Composites USA. DION resins, part of the Reichhold product line, are based on brominated resin technology. “But these types of resins can’t pass FST for aircraft interiors or the European standard for rail applications EN 45545,” notes Pauer.

“There is a simple test if you want to see how toxic smoke is from a composite,” says Schroeder at Scott Bader. “Set it on fire and note the color of the smoke. The toxicity increases with the darkness of color — white smoke has more water and less toxic fumes, while black smoke likely has very toxic fumes.”

Schroeder notes that Scott Bader is a member of Pinfa-NA, the North American sister group of Pinfa, which works to develop and promote non-halogen FR solutions in Europe. They hold workshops regularly, including several on plastics last year as well as electric vehicles.

Intumescents are non-toxic and can pass smoke and toxicity requirements, but work best at the surface of a composite.

Intumescent resins and gelcoats

“Our focus has been on intumescents,” says Pauer at Polynt. As explained in the April feature article, intumescents are substances that are activated by heat to expand and form a porous, carbonaceous char that thermally insulates the underlying composite and inhibits production of flammable volatiles. “This is the technology used in NORSODYNE laminating resin and FIREBLOCK gelcoats,” notes Pauer. “These products use no halogen, so they are non-toxic. NORSODYNE will pass the ASTM E-84 requirements for smoke. And the thicker the laminate, the better it performs.” This is because there is more intumescent additive, so the char layer gets thicker for more protection. It also explains why using NORSODYNE plus FIREBLOCK gelcoat provides better performance than NORSODYNE alone.

Filled resins

Though brominated resins still dominate the market overall, the most used resins for low-smoke FR composites are acrylic-based systems that are heavily filled with alumina trihydrate (ATH), including Ashland’s MODAR and Scott Bader’s Crestapol. Both are modified acrylic urethane polymers with little to no styrene, the latter being flammable. “These resins allow using up to 170 parts ATH for 100 parts resin along with fiber reinforcement,” explains Schroeder at Scott Bader. “So you are basically approximating an inorganic material by reducing the organic resin content.”

“MODAR gives good mechanical properties with low amounts of non-toxic smoke and good fire resistance,” explains Johnson at Ashland. “Due to its low viscosity, it offers the ability to add high amounts of ATH filler. You can also use phosphate and intumescent additives.” Normally, a resin with high ATH levels would be hard to process because it becomes viscous and doesn’t flow. These filled resins can also be brittle when cured. Johnson says the low-viscosity of these acrylic resins enables high filler loadings while maintaining processability. Meanwhile, their toughness is similar to polyurethanes, so they don’t become brittle when cured.

A quick discussion of acrylics. Though MODAR and Crestapol resins discussed here are thermosets, acrylics span a wide universe of materials encompassing thermoplastics, such as poly methyl methacrylate (PMMA, known by trade names Lucite and Plexiglas), as well as PMMA reacted with thermosets to form thermoset methyl methacrylates (MMA) and urethane acrylates.

Another note, Ashland and Scott Bader only sell their resins with ATH pre-mixed in Europe. In the US, both companies sell neat resin and provide technical support to help customers tailor the type and amount of ATH added, with advice on mixing ratios and procedures.

ATH-filled acrylics are a workhorse for low-smoke FR applications but require special considerations when using carbon fiber and resin infusion processing.

ATH and infusion

Pauer points out that infusing with ATH-filled resins can be challenging. “Some particles are larger than what you can infuse without filtering them out,” he says, noting that systems with more than 35-40 percent ATH don’t infuse well. Schroeder adds that carbon fiber also limits the use of ATH-filled systems, “because it’s too difficult to wet out the carbon fiber filament bundles, which are more tightly packed vs. glass fiber.” He adds that infusing ATH-filled systems into glass fiber fabrics is possible, “but you need to use open flow type of reinforcements like what SAERTEX has developed for LEO and like Chomarat produces with its G-flow fabrics. This helps to prevent filtering of the ATH.”

Mass transit applications

An example of a mass transit application is in the manufacture of 775 new train cars for San Francisco’s Bay Area Rapid Transit (BART) rail system. The first new cars entered service in 2018, and manufacturer Bombardier will complete deliveries in 2022.

According to Pauer, Polynt-Reichhold’s NORSODYNE H-81269TF intumescent laminating resin is used in the glass fiber-reinforced panels that form part of the floor assembly of these new cars. These panels provide fire protection from the carriage underside and integrate molded-in HVAC ducting, reducing floor assembly weight and thickness from the previous non-composite design.

Schroeder notes that Scott Bader is also qualifying Crestapol 1212 with a composites fabricator that is working on parts for the new BART vehicles. “Bombardier uses our products, but each is qualified per application,” he explains.

BART’s new subway cars use lightweight composites to achieve fire protection of the carriage underside, including NORSODYNE intumescent resin from Polynt-Reichhold.

SOURCE | Bombardier.

For bus applications, Polynt has developed an alternative approach using FIREBLOCK gelcoat to meet Docket 90 requirements, which include testing to ASTM E162 and ASTM E662. “We have customers making bus parts using resin transfer molding (RTM), where high ATH filler loadings create issues,” says Pauer. “By coating both sides of the part with FIREBLOCK 2330PAWK745 gelcoat, they can meet Doc 90 standards for flame and smoke while using conventional Polynt RTM resins.”

Electric Vehicles

This is a high-growth market for FR composites. “EV battery trays is an interesting application because you want to use carbon fiber for high mechanical strength, but this means you can’t use ATH,” says Schroeder. He also points out that experts are predicting a doubling in the energy density of batteries, which is required to achieve the vehicle driving range being demanded. “But if something should go wrong,” Schroeder continues, “and a battery cell catches on fire, you now have more of challenge dealing with that fire.”

Future developments

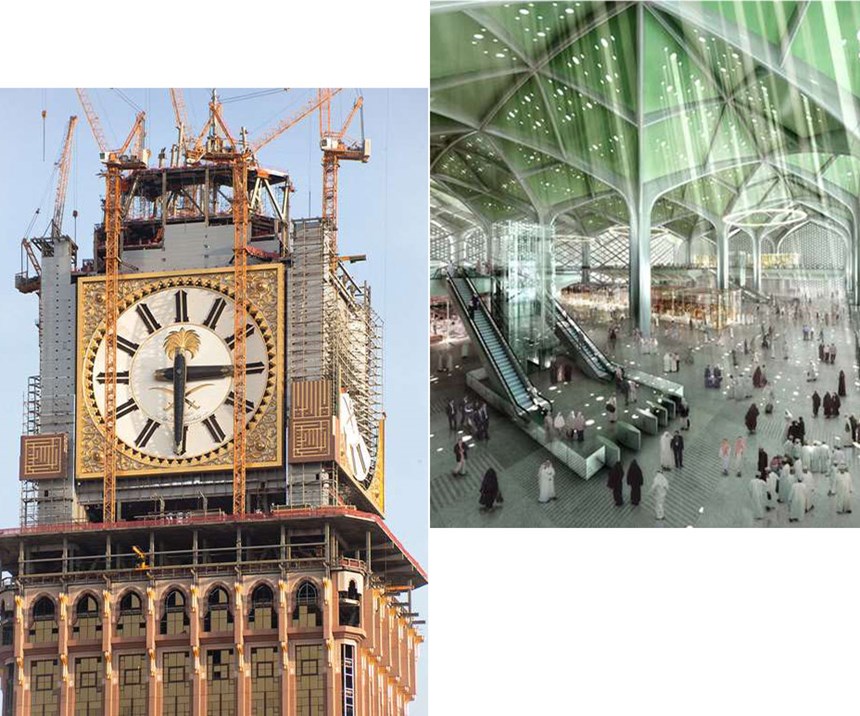

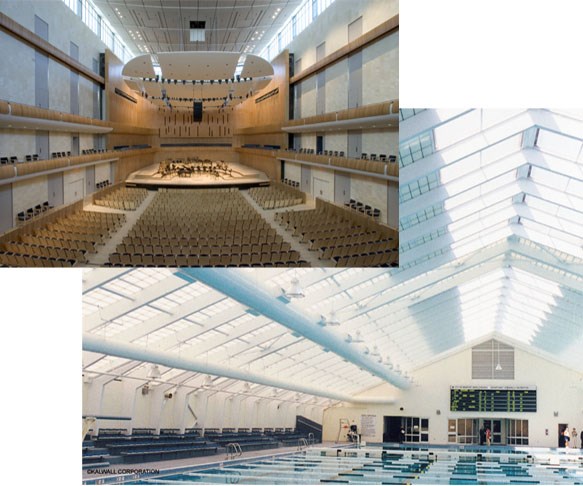

“There’s a lot going on and growth in all sectors,” says Johnson at Ashland, “but the most exciting market is architectural projects. This is such an untapped area, and using composites enables large, curved surfaces plus lightweight for multistory buildings. We see it breaking through with the leading architects globally.” Pauer has been a staunch advocate for composites in construction and has been a key member of ACMA’s architectural division, which has published guidelines for using composites in buildings, including a large section on fire regulations and testing.

The examples in the slideshow above also show Scott Bader’s development work in buildings/construction, but Schroeder voices some concerns. “For these large, commercial markets, FR composite products have to have robust processability. If you’re not going to make products reasonably easy for molders to work with, they won’t succeed in the market.” He notes that all companies continue to look for solutions that perform like halogenated systems but without the toxicity.

What about poly furfuryl alcohol (PFA)? This bio-derived resin that reportedly performs as well as phenolic is being sold by SHD Composites and Composites Evolution for use in rail applications. “The concern with PFA is getting the water out during processing because it is a condensation reaction polymer, just as phenolic is,” Schroeder explains. Perhaps this is why products so far are based on prepreg and not infusion.

FR solutions are moving away from just one ingredient and instead using a whole system of resins, reinforcements and coatings to allow high fiber volume.

Schroeder notes that fabricators are moving away from looking at one ingredient and instead considering a whole system, including laminate plus coatings. He cites the SAERTEX LEO SYSTEM as an example (see April feature article). “People are using FR resins plus intumescent gelcoats and veils like Tecnofire,” says Schroeder. “These solutions allow a high fiber volume.”

“Resin will always burn, except for phenolics,” he continues. “My hope is that we get something that has fire retardancy akin to phenolics but that you can infuse to produce high fiber volume structures using carbon fiber.” He adds that Scott Bader is pursuing some promising developments, but nothing is ready for market just yet.

“As a resin provider, we are supplying both the fuel for fire and the means for technology to resist it,” says Johnson. “The challenge is having a portfolio of high FR performance products and chemistries as well as the knowledge and test history to know what works well and why.” And that is the expertise offered by these resin suppliers. Feel free to contact me (ginger@compositesworld.com) for more information or to connect with these and other experts.

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreRead Next

Withstanding fire without the weight

New composites meet stringent fire requirements while lightweighting ships, rail cars and battery boxes for electric cars and planes.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More