James Webb Space Telescope reaches major milestone as primary mirror unfolds

Full deployment of the 21-foot, gold-coated primary mirror completes the final stage of all major spacecraft deployments in preparation for science operations.

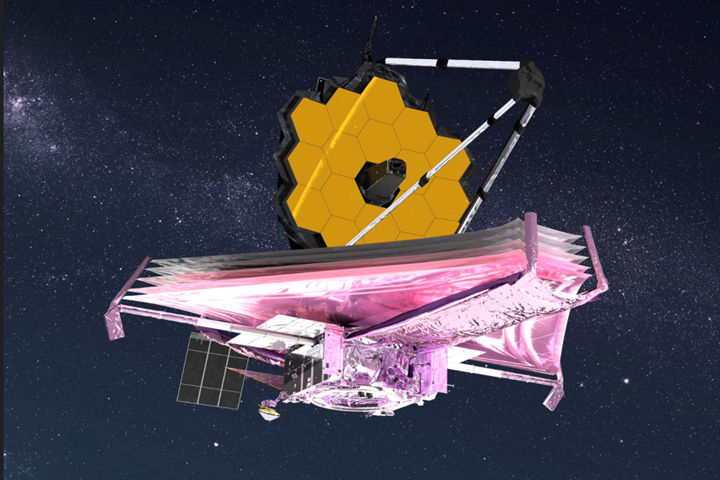

As of Jan. 8, 2022, NASA’s (Washington D.C., U.S.) James Webb Space Telescope (JWST) team fully deployed its 21-foot, gold-coated primary mirror, successfully completing the final stage of all major spacecraft deployments (including the 70-foot sunshield) since its Dec. 25 launch, to prepare for science operations. The telescope makes ample use of composite materials.

A joint effort with the European Space Agency (ESA) and Canadian Space Agency (CSA), the Webb mission will explore every phase of cosmic history, from within our solar system to the most distant observable galaxies in the early universe.

“NASA [has] achieved another engineering milestone decades in the making. While the journey is not complete, I join the Webb team in breathing a little easier and imagining the future breakthroughs bound to inspire the world,” says NASA Administrator Bill Nelson. “The James Webb Space Telescope is an unprecedented mission that is on the precipice of seeing the light from the first galaxies and discovering the mysteries of our universe. Each feat already achieved and future accomplishment is a testament to the thousands of innovators who poured their life’s passion into this mission.”

The two wings of Webb’s primary mirror had been folded to fit inside the nose cone of an Arianespace (Évry-Courcouronnes, France) Ariane 5 rocket prior to launch. After more than a week of other critical spacecraft deployments, the Webb team began remotely unfolding the hexagonal segments of the primary mirror, said to be the largest ever launched into space. This was a multi-day process, with the first side deployed Jan. 7 and the second Jan. 8.

Mission Operations Center ground control at the Space Telescope Science Institute in Baltimore, Md., U.S. began deploying the second side panel of the mirror at 8:53 a.m. EST. Once it extended and latched into position at 1:17 p.m. EST, the team declared all major deployments successfully completed.

JWST will now begin moving its 18 primary mirror segments to align the telescope optics. The ground team will command 126 actuators on the backsides of the segments to flex each mirror — an alignment that will take months to complete. Then the team will calibrate the science instruments prior to delivering Webb’s first images this summer.

This artist’s conception of the James Webb Space Telescope (JWST) in space shows all its major elements fully deployed. The telescope was folded to fit into its launch vehicle, and then was slowly unfolded over the course of two weeks after launch. Photo Credit: NASA GSFC/CIL/Adriana Manrique Gutierrez

“I am proud of the team — spanning continents and decades — that delivered this first-of-its kind achievement,” says Thomas Zurbuchen, associate administrator for the Science Mission Directorate at NASA headquarters in Washington. “Webb’s successful deployment exemplifies the best of what NASA has to offer: the willingness to attempt bold and challenging things in the name of discoveries still unknown.”

Soon, Webb will also undergo a third mid-course correction burn — one of three planned to place the telescope precisely in orbit around the second Lagrange point, commonly known as L2, nearly one million miles from Earth. This is Webb’s final orbital position, where its sunshield will protect it from light from the sun, Earth and moon that could interfere with observations of infrared light. JWST is designed to peer back more than 13.5 billion years to capture infrared light from celestial objects, with much higher resolution than ever before, and to study our solar system, as well as distant worlds.

“The successful completion of all of the Webb Space Telescope’s deployments is historic,” concludes Gregory L. Robinson, Webb program director at NASA headquarters. “This is the first time a NASA-led mission has ever attempted to complete a complex sequence to unfold an observatory in space — a remarkable feat for our team, NASA and the world.”

For more information about the Webb mission, visit this link.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More