Lanxess thermoplastics lightweight Geely front end carrier component

Evaluated and tested by Lanxess, the high-modulus, high-flow PA6 material reinforced with 50% glass fiber achieves high stiffness and strength for the multi-component assembly.

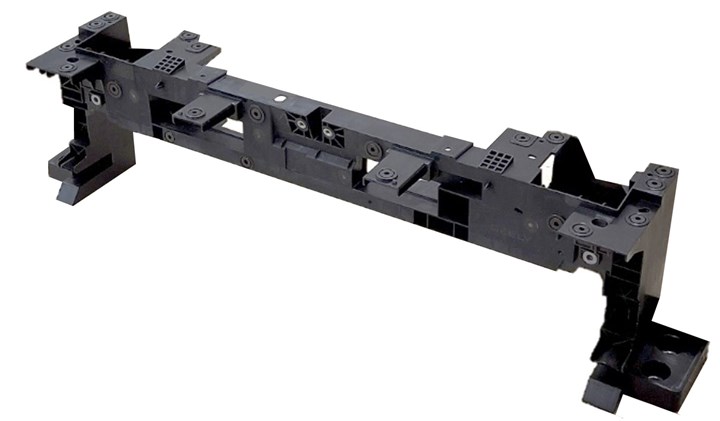

The front end carrier (FE) structural component. Photo Credit: Lanxess

Chinese car manufacturer Geely (Hangzhou) has selected specialty chemicals company Lanxess (Cologne, Germany) as supplier of choice for an innovative front end carrier (FE) structural component, which will be used in a coming passenger car model. Developed using Lanxess’ Durethan BKV50H2.0 EF, a high modulus polyamide 6 (PA6) thermoplastic material with 50% glass fiber reinforcement, the component’s design concept is a state-of-the-art hybrid design solution that is said to go beyond the traditional square/rectangular form FE structure.

While the lower cooler mounting is in sheet metal, the complex upper member was developed using this highly filled and heat stabilized Durethan BKV50H2.0 EF material, which Lanxess says is well suited for structural components that require high stiffness and strength. Overall, the full plastic design for the upper section caters to a wide range of requirements for the multi-component assembly, including the achievement of multiple savings targets.

Lanxess was chosen by Geely as material supplier based on its expertise in handling the part design as well as the suitability of its Durethan polyamide material. However, “Designing a plastic structural component and providing the right material is not enough,” notes Tsui, project manager at the Lanxess High Performance Materials (HPM) business unit. “Considering the overall market background, customer expectations, understanding the tasks on hand and preparing different potential design proposals for the FE structure was also key in developing this project.”

To support maximum component performance and efficient processing, Lanxess established the Pocan and Durethan EF and XF product lines, a broad range of easy-flow polybutylene terephthalates (PBT) and PA6 and 66 grades, which includes the Durethan BKV50H2.0 EF material used for Geely’s FE structural component. “EF” stands for “EasyFlow,” “XF” for “XtremeFlow.” According to Lanxess, these products display unusually high stiffness and strength and, despite their high filler content, can still be processed as easily and efficiently as comparable standard materials. “Smart materials offer attractive advantages for design and manufacturing provide designers with entirely new options,” says Wei Lin, Lanxess key account manager.

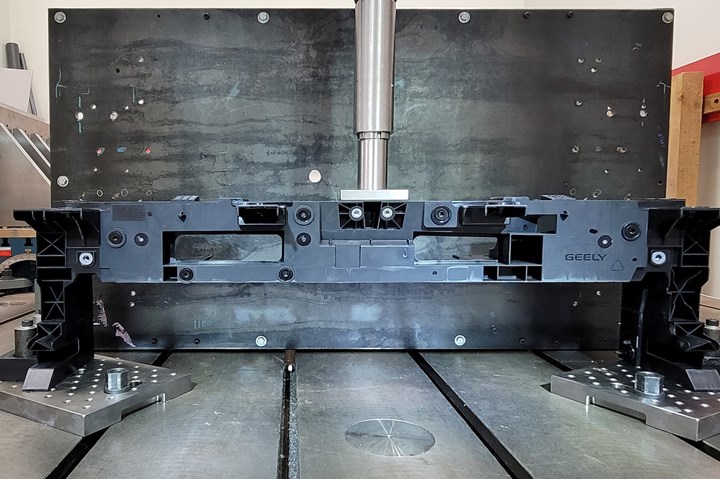

Lanxess comprehensive part testing services conclude new application developments to ensure highest safety and reliable performance according to customer specifications and in correlation with Lanxess advanced CAE methodologies. Photo Credit: Lanxess

Apart from high-tech thermoplastics, Lanxess also offers extensive know-how and experience, as well as state-of-the-art design and simulation methods, and part evaluation and testing. For example, HiAnt, its integrated service package for lightweight solutions, aims to help Lanxess customers achieve maximum performance while minimizing weight. Lanxess also has a state-of-the-art test laboratory and the corresponding specialist employees, and can offer an extensive range of testing facilities.

Geely Holding Group is a global innovative technology group engaged in the design, R&D, production, sales and service of vehicles, powertrains and key components, as well as mobility services and digital technologies.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.