LANXESS Corporation

111 RIDC Park West Dr.

Pittsburgh, PA 15275 US

800-LANXESS | 412-809-1000

us.info@lanxess.com

lanxess.com

About LANXESS Corporation

The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, additives, specialty chemicals and plastics.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

LANXESS Corporation Supplies the Following Products

- Colorant, pigments

- Flame/smoke-suppressant additives

- Nylon (polyamide)

- Polybutylene terephthalate (PBT)

- Thermoplastic, long fiber-reinforced (LFRT)

- Thermoplastic, short fiber-reinforced

Trade Names Offered by LANXESS Corporation

- Tepex

Editorial, News, and Products

-

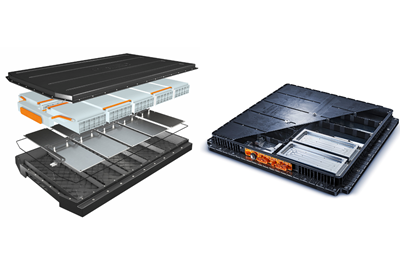

Kautex wins SPE Grand Innovation Award for thermoplastic composite battery enclosure with integrated cooling

Second award for Pentatonic Battery Enclosures touts innovative design, enabling two-phase cooling for safe temperatures, high charging rates.

-

People in composites: October 2023

New personnel and leadership appointments have been announced this past month by Johns Manville, Airbus, Aquapak Polymers, ZeroAvia, Daher, Velocity Composites and Fives.

-

Robotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

-

Lanxess, DSM Engineering Materials venture launched as Envalior

New global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business to offer a variety of material solutions.

-

Mass, cost, durability improvements: EV battery enclosures, Part 2

As interest grows in composite battery covers and trays, composite materials suppliers work to meet current and future needs of automakers, battery module producers.

-

CFRTP enables better, greener smartphones

Carbon Mobile’s “monocoque” design eliminates separate case, cover and frame, better protects electronics and simplifies disassembly.

-

FMG releases market analysis on advanced materials

U.K.-based Future Materials Group (FMG) has issued a new report that assesses the outlook for and opportunities in the advanced materials sector.

-

Lanxess expands Tepex flowcore composite range

Focusing on lightweight components for cars, sports equipment and consumer goods, the long fiber-reinforced thermoplastic enhances ductility, recylability and processability.

-

Lanxess reveals highly sustainable Scopeblue composite material series

PA6 glass fiber-reinforced compound under Lanxess’ new Scopeblue series is made from 92% sustainable raw materials, with content goals headed toward 100%.

-

Lanxess launches renewable, biocomposite material

The material combines natural flax fibers with bio-based polylactic acid, which acts as the matrix, for a material that is 100% recyclable.

-

Lanxess Tepex composite material lightweights luxury sedan load compartment well

PA6 Tepex dynalite thermoplastic blank reinforced with continuous glass fiber fabrics withstands high mechanical stresses and achieve 30% lighter weight than comparable sheet metal components.

-

Lanxess thermoplastics lightweight Geely front end carrier component

Evaluated and tested by Lanxess, the high-modulus, high-flow PA6 material reinforced with 50% glass fiber achieves high stiffness and strength for the multi-component assembly.

-

Lanxess halogen-free, flame-retardant compounds aim for electromobility

Glass-fiber-reinforced PA6 compounds, Durethan BKV30FN01 and Durethan BKV30FN04 DUS064, are designed for use in flame-retardant, thick-walled components.

-

Lanxess, INFAC develop composite battery module housing

The halogen-free, flame-retardant and glass fiber-reinforced polyamide 6 (PA6) part lowers battery module assembly weight, improves insulation and flame resistance and retains a high level of functional integration.

-

Resin shortages continue to affect composites supply chain

Power outages caused by mid-February’s U.S. winter storms led to immediate shortages from Gulf Coast petrochemical companies. Fabricators continue to report shortages.

-

Lanxess introduces new water-based dispersions for glass fiber sizing

Expansion of Lanxess’ Trixene Aqua BI product family offers excellent crosslink and adhesion promoters for aqueous coating systems, improves sizing formulation chemical and mechanical resistance.

-

Composites as auto-body reinforcements

Hybrid structural-reinforcement technology expands options, gains applications, markets.

-

Carbon Mobile carbon fiber smartphone unlocks RF signal permeation capabilities

Housing is made from Lanxess Tepex thermoplastics reinforced with 1K continuous carbon fiber using Carbon Mobile’s patented HyRECM process for a “radio-enabled” composite material.

-

Bespoke process produces composite brake pedal every minute

Three composite materials are used to create structural composite member that meets demanding mechanical requirements.

-

Thermoplastic composite structure replaces metals on safety-critical brake pedals

First all-composite brake pedals developed by Boge Rubber & Plastics Group are lighter, stiffer, stronger and offer improved driving haptics.

-

Lanxess thermoplastic material targets high flame-retardant properties

Tepex continuous-fiber-reinforced thermoplastic composites variants with a PA6 matrix are certified as UL 94 V-0 and retain a high degree of strength, rigidity and energy absorption.

-

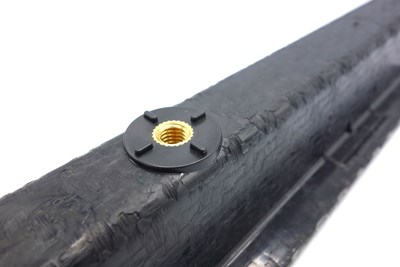

Lanxess extends use of composites to extrusion blow molding

The process demonstrates its capabilities to boost the mechanical performance of blow-molded components in high-stress areas.

-

Lanxess launches bio-based prepolymer line Adiprene Green

The bio-based prepolymer line are easy to handle and enable a suitable replacement for existing fossil-based polyether prepolymers.

-

Lanxess shifts to recycled composites with Durethan ECO polyamide products

The PA6-based products feature waste glass in loadings of 30, 35 and 60%. Lanxess is shifting to a circular economy to help improve the company’s carbon footprint.

-

Lanxess presents thermoplastics for automotive applications

The company is showcasing use of its composite materials in A-pillar automotive structures and electric vehicle charging applications at the VDI Congress PIAE virtual event in July.

-

People in Composites: March 2020

ACMA, KraussMaffei, FACC, LANXESS, and UAMMI announce new hires in the composites industry.

-

Tepex thermoplastic composites demonstrate fire resistance for EVs

Bond-Laminates’ continuous-fiber-reinforced thermoplastic composite has passed flammability tests for car interiors.

-

Tepex reinforces child seat headrest demonstrator

Continuous fiber-reinforced thermoplastics and a new PCIM-based production process demonstrate potential for lightweight structural safety components.

-

Composite insert as a structural reinforcement for A-pillars

A Porsche structural A-pillar reduces weight and increases strength with a hybrid part combining thermoplastic composites, steel and structural foam.

-

Plastic-metal hybrid auto structure named SPE Hall of Fame winner

The plastic-metal hybrid front end automotive structure, built by Ford Motor Co. with LANXESS glass fiber-filled PA6 resin, reduced costs and weight compared to all-steel structures.

-

Continuous fiber-reinforced thermoplastics data added to CAMPUS database

The new data, which will be released in October, is the result of an ongoing material standardization and characterization effort led by German reinforced plastics company AVK.

-

LANXESS commissions two new production lines for Tepex thermoplastic composites

The 1,500-square-meter expansion to the Brilon, Germany facility increases production of the continuous fiber-reinforced thermoplastic composites by 50%.

-

LANXESS thermoplastic composites used in Audi A8 rear seat shell

LANXESS rear seat shell showcases the company’s continuous-fiber-reinforced composites role in large-scale production of structural components for automotive.

-

Thermoplastic overmolded thermosets, 2-minute cycle, one cell

Adhesive-free, functionalized hybrid composites enabled by industry-first, integrated molding cell.

-

LANXESS expands production capacity for continuous fiber-reinforced thermoplastic composites

The company’s Tepex continuous fiber-reinforced thermoplastic composites are used in series applications in the automotive, consumer electronics and sports industries.

-

Composite + metal: Hollow-profile hybrid technology

LANXESS extends plastic-metal hybrids to tubular structures.

-

Tepex Dynalite backseat over 40% lighter than steel part

Continuous glass fiber layers designed to withstand bending and torsional stress.

-

Current state of the M&A and capital markets – sell, sell, SELL!!

Current market conditions suggest that 2017 should see sustained M&A activity, despite the 2016 reduction.

-

Honda’s Clarity Fuel Cell sedan features hybrid-molded rear bumper beam

The rear bumper beam is made of the Tepex composites material from the Lanxess subsidiary Bond-Laminates.

-

Turnkey manufacturing systems: Materials, markets and maturation

Automated production cells promise affordability and less risk in scaling up composites production, but are they really the path forward?

-

Slideshow of SPE ACCE 2015

A look at the 15th edition of SPE’s Automotive Composites Conference & Exhibition (ACCE).

-

Thermoplastic composites feel the love at NPE2015

At NPE2015, some of the key players involved in thermoplastic composites exhibited a variety of solutions that are leading growth in new and emerging markets.

-

SPE ACCE report

Automotive composites still on the horizon — are they getting closer?

-

CAMISMA’s car seat back: Hybrid composite for high volume

Recycled fibers, in-situ polymerized PA12 and steel inserts combined in one-shot process to cut weight 40 percent at competitive cost, cycle time and safety.

-

SPE ACCE 2014 report

Automotive composites still on the horizon — are they getting closer?

-

Spare wheel well: Functional integration

Gas-assist injection molding enables one-piece, one-shot thermoplastic composite/metal hybrid.

-

SPE ACCE 2011: Growing again

The Society of Plastics Engineers’ 11th conference on automotive composites fields a top slate of speakers and attracts its largest crowd.

-

CNTs ride a rising tide of nanotech optimism

Dr. Louis Pilato offers facts, figures and comment on the growing utility of carbon nanotechnologies in composites applications.