NASA’s Artemis I mega rocket launches Orion to moon

The agency’s Orion spacecraft — showcasing an abundance of composite components and structures — launched 1:47 a.m. on Nov. 16, and is on its way to the moon as part of the Artemis program.

NASA’s SLS rocket carrying the Orion spacecraft launches on the Artemis I flight test, Wednesday, Nov. 16 from Launch Complex 39B at NASA’s Kennedy Space Center in Florida. NASA’s Artemis I mission is the first integrated flight test of the agency’s deep space exploration systems: the Orion spacecraft, Space Launch System (SLS) rocket and ground systems. Photo Credit, all images: NASA/Joel Kowsky

Following a successful launch of NASA’s Space Launch System (SLS) rocket, the agency’s Orion spacecraft — showcasing an abundance of composite components and structures — is on its way to the moon as part of the Artemis program. Carrying an uncrewed Orion, SLS lifted off for its flight test debut at 1:47 a.m. EST on Nov. 16 from Launch Pad 39B at NASA’s Kennedy Space Center in Florida.

Orion’s composite features include an Airbus (Bremen, Germany) built European Service Module (ESM), which has a primary structure making high use of carbon fiber composites, Beyond Gravity’s (Zürich, Switzerland) composite large connector (universal stage adapter) that links the launch vehicle and the service module and a composite heat shield design created by Lockheed Martin (Bethesda, Md., U.S.) engineers.

The launch is the first leg of a mission in which Orion is planned to travel approximately 40,000 miles beyond the moon and return to Earth over the course of 25.5 days. Known as Artemis I, the mission is a critical part of NASA’s moon to Mars exploration approach, in which the agency explores for the benefit of humanity. It’s an important test for the agency before flying astronauts on the Artemis II mission.

After reaching its initial orbit, Orion deployed its solar arrays and engineers began performing checkouts of the spacecraft’s systems. About 1.5 hours into flight, the rocket’s upper stage engine successfully fired for approximately 18 minutes to give Orion the big push needed to send it out of Earth’s orbit and toward the moon.

Orion has separated from its upper stage and is on its outbound coast to the moon powered by its service module, which is the propulsive powerhouse provided by the European Space Agency (ESA) through an international collaboration.

“It’s taken a lot to get here, but Orion is now on its way to the moon,” Jim Free, NASA deputy associate administrator for the Exploration Systems Development Mission Directorate, says. “This successful launch means NASA and our partners are on a path to explore farther in space than ever before for the benefit of humanity.”

Over the next several hours, a series of 10 small science investigations and technology demonstrations, called CubeSats, will deploy from a ring that connected the upper stage to the spacecraft. Each CubeSat has its own mission that has the potential to fill gaps in our knowledge of the solar system or demonstrate technologies that may benefit the design of future missions to explore the moon and beyond.

Orion’s service module will also perform the first of a series of burns to keep the launch vehicle on course toward the moon approximately eight hours after launch. In the coming days, mission controllers at NASA’s Johnson Space Center in Houston will conduct additional checkouts and course corrections as needed. Orion is expected to fly by the moon on Nov. 21, performing a close approach of the lunar surface on its way to a distant retrograde orbit, a highly stable orbit thousands of miles beyond the moon.

Engineers previously rolled the SLS rocket back to the Vehicle Assembly Building (VAB) on Sept. 26 ahead of Hurricane Ian and after waving off two previous launch attempts Aug. 29 due to a faulty temperature sensor, and Sept. 4 due to a liquid hydrogen leak at an interface between the rocket and mobile launcher. Prior to rolling back to the VAB, teams successfully repaired the leak and demonstrated updated tanking procedures. While in the VAB, teams performed standard maintenance to repair minor damage to the foam and cork on the thermal protection system and recharge or replace batteries throughout the system.

View more photos of Artemis I here.

Related Content

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

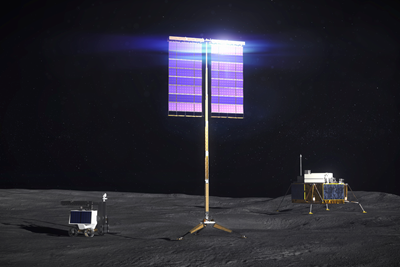

Three companies chosen to advance NASA deployable solar array

Astrobotic Technology, Lockheed Martin and Honeybee Robotics awarded $19.4 million to prototype build and test solar array systems to power moon exploration under Artemis. Current mast designs incorporate carbon fiber-based technologies.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More