National Composites Centre unveils digital composites technologies

The U.K.’s National Composites Centre unveils new composites manufacturing technologies, marking the culmination of a two-year, £36.7m digitization project.

The National Composites Centre (NCC) in Bristol, U.K. CW photo | Scott Francis

The U.K.’s National Composites Centre (NCC, Bristol, U.K.) held an event on Friday February 28 celebrating the center’s investment in an additional 9,948 square meters of space and 10 state of the art digital manufacturing technologies.

The investment is part of a digital capability acquisition program known as iCAP, a £36.7 million investment in 10 technologies tailor-made to the NCC’s specifications with the goal of speeding the development of composites manufacturing for a range of markets. The iCAP program is funded by Aerospace Technology Institute (ATI, Cranfield, U.K.), Local Enterprise Partnership and the High Value Manufacturing Catapult (Solihull, U.K.).

An overmolded carbon fiber part produced using the NCC’s new overmolding cell. CW photo | Scott Francis

“Our mission is to mature composites technology out of the academic research area into a production-ready environment,” says Rich Hooper, director of engineering and manufacture at NCC.

To that end, for the past two years, a team of NCC engineers, researchers, software architects, roboticists and textile experts have been exploring how digital technologies can make composite parts easier to design and improve the speed and cost of manufacture.

The aerospace sector is a significant driver of the demand for high-rate composites manufacturing. According to the NCC, using current, labor-intensive techniques, manufacturers can only make 6 pairs of wings per month — the likely rate of production needed for a future single aisle aircraft is 100 pairs per month. The NCC is a partner in the Airbus Wing of Tomorrow Programme, which has a goal of developing a high-rate commercial aircraft wing structure manufacturing process involving more automation, fewer parts, better parts integration, faster cycle time, faster NDI and faster assembly.

NCC’s new pilot line. CW photo | Scott Francis

The NCC’s new equipment includes a new pilot line which will be used for the Wing of Tomorrow. The high rate deposition system comprises two huge industrial robots that automate the wing production process. Weighing 45 tonnes and 24 tonnes respectively, the robots measure, cut, lift and place pieces of carbon fiber fabric (‘plies’) with millimetric accuracy. 5-meter wide strips of composite material, up to 20-meters long, can be laid in one precise movement, potentially cutting the number of fabric components required from around 100,000 to just 150, and reducing wing-build time from one week to one day.

Once the plies are laid the wing is vacuum bagged and moves into a new 20 -meter long oven equipped with large scale resin infusion tanks. The wing is cured in the oven at 180º C within 8 hours.

The new technologies at the NCC are not only helping to re-think how aircraft wings are made, but are also helping to bridge the gap between academic research and industrialization in a range of markets from construction to oil and gas.

“[This] investment in 10 new world-leading composites capabilities will enable us to develop the wings and engines for the aircraft of the future, work on technologies that will define the way we produce and store energy and transform the way we build infrastructure,” says Richard Oldfield, CEO of the NCC.

“Membership has doubled in the last year, but has doubled out of the non-traditional sectors,” he adds. “That really exciting … it really does open up fantastic opportunities.”

Other technologies include a circular braider from Eurocarbon (Sittard, Netherlands), the largest of its kind in Europe, which automatically weaves up to 288 individual strands of high strength carbon fiber to create hollow 3D shapes (or geometries), for products such as pipes or aircraft propellers.

A new overmolding cell supplied by Engel (Schwertberg, Austria) features a horizontal 1,700 tonne press, injection barrel temperatures/pressures up to 420°C and 2,000 bar with a shot volume up to 6,400 cubic meters. The goal of the overmolder is to enable the mass-production of composite components.

“Composite overmolding technology specifically allows for the rapid manufacture of net-shape structural thermoplastic composites,” says Enrique Garcia, chief technology officer at the NCC. “It combines both laminate thermoforming and polymer injection molding in one automated process, thus structural components with a valuable combination of high strength and integrated complex design features are able to be manufactured with a very low cycle time.” (Learn more.)

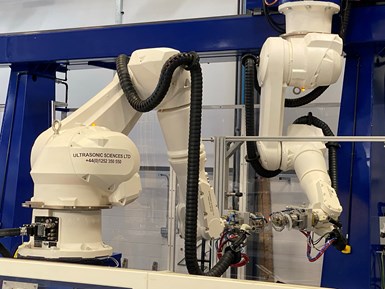

Ultrasonic NDI is conducted by two robots working in unison. CW photo | Scott Francis

For nondestructive inspection (NDI) of parts, the NCC has commissioned two, 3-meter high robots that work in unison to scan the component by beaming ultrasound through high-pressure water jets. The system then measures the time taken for sound to travel through the part, alerting operators to any anomalies.

New technologies at the NCC also include an automated preforming cell, a Coriolis Composites (Queven, France) C5 automated fiber placement (AFP) robotic gantry solution (learn more) and an Electoimpact (Mukilteo, Wash., U.S.) AFP/ATL machine.

Related Content

SGL Carbon carbon fiber enables German road bridge milestone

A 64-meter road bridge installed with carbon fiber reinforcement is said to feature a first in modern European bridge construction, in addition to reducing construction costs and CO2 emissions.

Read MoreCCG FRP panels rehabilitate historic Northamption Street Bridge

High-strength, composite molded, prefabricated panels solve weight problems for the heavily-trafficked bridge, providing cantilever sidewalks for wider shared use paths.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More