ST Bungalow to demonstrate fiberglass roofing solution from recycled wind blades

The New York-based startup recently partnered with a wind blade recycling company and plans to produce its first full-scale prototypes this year.

ST Bungalow so far has 3D printed and tested miniature models of its fiberglass composite roof form solution. Shown here, the forms are molded into arches or other shapes for maximum tensile strength. Photo Credit, all images: ST Bungalow

Fiberglass and concrete roofing concept developer ST Bungalow (Croton-on-Hudson, N.Y., U.S.) reports that it recently signed a memorandum of understanding (MoU) with a recycling company, for the use of recycled wind blade material in ST Bungalow LLC’s patented flat roof concept.

ST Bungalow LLC, a spin-off from solar technology company Solar-Tectic LLC, was founded in 2013 with the initial goal of developing a low-cost eco-friendly housing unit using a flat roofing concept that could also support the installation of solar panels. The housing units — called “Bungalows” — were designed as a housing solution for impoverished areas. The walls would be constructed from compressed earth blocks (CEB), which have a low carbon footprint because they use very little concrete, notes Ashok Chaudhari, managing director and co-founder of both ST Bungalow and Solar-Tectic LLC. For the Bungalow roofs, Chaudhari says the original plan was to develop a flat roofing system made from CEBs.

The fiberglass formwork serves as both the interior ceiling and a reinforcing structure for a thin layer of exterior concrete. Shown here as a miniature model.

In the process of developing the Bungalow housing concept, Michael Mollinelli, an architect Chaudhari and his team worked with for the project, presented an idea for a roof design that was a stronger, more durable fiberglass composite-based solution. This idea was patented in 2017 by ST Bungalow and Mollinelli, and involves a fiberglass composite formwork shaped into one of several designs, with a thin layer of concrete layered onto the top. The overall solution serves as both an exterior roof and an interior ceiling for the Bungalow, and could also be used for flooring and potentially also for bridge decking.

Until recently, Chaudhari says, the fiberglass forms seemed prohibitively expensive to manufacture for the company to begin commercial production. “Our roof idea has now suddenly become very relevant because of wind blade recycling,” he says. “The wind industry right now doesn’t have a lot of uses for the fiberglass recycled from blades, but for us, it’s the same material we need for our roof product.” He says that the recycled fiberglass composite will be mechanically shredded into a powder and then molded into a new compound with the addition of small amounts of virgin or recycled resin.

One of the advantages to ST Bungalow’s proposed roofing solution is simple transport and installation. This drawing shows 28 trapezoidal forms neatly stacked within one container.

This solution is intended to serve as a more sustainable, lower-concrete alternative to corrugated steel roofs or concrete roofs reinforced with steel or fiber-reinforced polymer (FRP) rebar. “The basic idea is that the shape and the form of the fiberglass allows for the tensile strength needed to push the concrete to maximum compression,” Chaudhari explains, which minimizes the amount of concrete needed. The use of composites also eliminates corrosion issues from moisture, and installation of the system would also be simpler and cheaper than installing rebar because it would take less time for workers to install, he says.

So far, the company has 3D printed and tested miniature models of the technology, and plans to build, test and certify full-scale versions this year using recycled fiberglass. From there, ST Bungalow hopes to find construction and/or venture capitalist partnerships in order to scale the technology up for commercial production.

Related Content

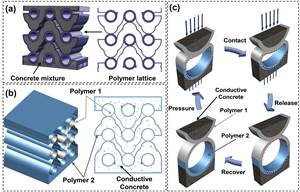

21st century concrete: composite metamaterial with super compressability, energy harvesting

Material comprising 3D-printed, auxetic, reinforced polymer lattices in conductive cement matrix can compress up to 15% and generate electricity for lightweight, mechanically tunable structures with energy harvesting and sensing.

Read MoreFiberglass conduit manufacturer grows into new products, infrastructure applications

Texas-based Champion Fiberglass, a five-time CW Top Shops honoree, expands its success in the fiberglass composite conduit market into new applications and products, looking toward future automation and sustainability initiatives.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

Read MoreRead Next

Composite panels aid design of prefabricated apartment addition

Glass fiber/epoxy sandwich panels achieved structural requirements, complex geometries and challenging installation needs for London apartment renovation.

Read MoreSolico engineers composite elements for Netherlands infrastructure project

Solico partners with Advantage Composites to aid in engineering all composites components and their supporting structures for Phase 3 of an extensive viaduct and underpass reconstruction.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg)