Victrex and Bond partner for 3D printing PAEK parts

The companies are collaborating to combine Victrex’s PAEK material expertise and Bond’s 3D printing technology for an accelerated pathway to 3D-printed PAEK part production.

Victrex (Cleveleys, Lancashire, U.K.) has announced a multimillion euro investment in Bond High Performance 3D Technology (Enschede, Netherlands), a partnership intended to provide customers with an accelerated route to market for 3D-printed PAEK parts.

Bond has developed a differentiated 3D printing machinery and software combination which reportedly can produce high-strength parts from existing grades of high-performance thermoplastics. The common objective, according to Victrex, is to link Victrex’s material application and customer expertise with Bond’s 3D processing technology to produce functional, strong parts that maximize component performance. Bond’s technology is reportedly capable of printing complex, functional parts made of PEEK with excellent mechanical properties, including in the z-direction. This enables the additive manufacture of high-strength, isotropic parts with properties comparable to conventional molded or machined PEEK parts.

Victrex and Bond will initially focus their new collaboration on demonstrating the potential in the spine and the semiconductor segments. These will use commercially available products such as PEEK-OPTIMA from Invibio Biomaterial Solutions, Victrex’s medical business, or VICTREX PAEK thermoplastic. In the future, this ability to print functional parts from existing PEEK grades may also have value in aerospace, energy, automotive, manufacturing and engineering applications.

Currently, Bond’s 3D hardware and software are in the beta-phase. A clear development plan is in place for upscaling and installing additional 3D printing machines later this year. This is expected to mark the next phase and drive the transition from development to first part qualification and early stage production. Bond was founded in 2014, delivered a “proof of concept” 3D printer in 2016 and, following investment in the same year, then realized functional models and prototypes.

“Our investment in Bond´s 3D technology is a logical way to accelerate 3D-printed PAEK/PEEK parts to market,” explains Jakob Sigurdsson, Victrex CEO. “We need to ensure that all the key elements, including material, process and hardware, are aligned to fulfill our goal of enabling our customers to manufacture 3D-printed PAEK components for critical high-performance applications. We’re now at a stage where the technology is sufficiently developed to embark on exciting development programs.”

“We found that the market needs strong functional parts made from high-performance polymers that can be used not only for prototyping but for production,” says Gerald Holtvlüwer, CEO, Bond High Performance 3D Technology. “With our dedicated focus on 3D printing technology for high-performance polymers, we were able to develop a technology to achieve the full strength of existing PAEK and PEEK polymers. This includes the strength in the z-direction, which is the most difficult to achieve with high-performance polymers in general and PEEK in particular. We’re excited to partner with a world leader in PAEK polymer-based solutions. Victrex´s material know-how and their strong marketing and sales activities are a perfect channel to market for us and a complement to our pioneering technology.”

“Collaboration and partnerships are the key to establishing the necessary supply chain for additive manufactured PAEK parts,” adds Sigurdsson. “After focusing, as part of Innovate UK projects, on new optimized PAEK/PEEK materials, partnering with Bond is the next important stage. Their advanced technical capabilities and ambitious, innovative culture will help to meet the needs of industries that can benefit from the exceptional material properties PAEK brings, in combination with the manufacturing benefits and freedom that their AM technology offers.”

Related Content

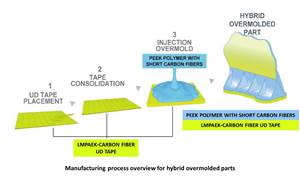

Tool Gauge, Victrex partner to develop co-molded composite aircraft parts

Novel hybrid overmolding technology achieves novel thermoplastic composite parts to replace machined aluminum components on commercial aircraft, as well as reduce manufacturing costs and timeline.

Read MoreHitachi Rail chooses Roboze printers, materials including carbon fiber/PEEK for railway spare parts

The Roboze ARGO 500 will be used at Hitachi Rail factories in Naples, Italy and Maryland, U.S. to reduce cost and delivery times for prototypes and spare parts.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

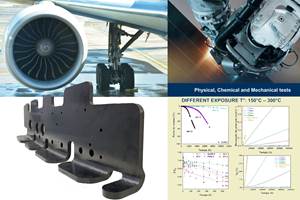

Read MoreDaher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;width=70;height=70;mode=crop)