CAMX 2022 exhibit preview: Michelman

Michelman spotlights its Hydrosize flagship line for composite interface adhesion and Unyte technologies targeting technical textiles at CAMX 2022.

Michelman (Cincinnati, Ohio, U.S.) is a manufacturer of advanced materials, including fiber sizing and surface modifiers used to produce fiber-reinforced plastic (FRP) composites. The company develops novel water-based functional dispersions and emulsions of polymers, resins and waxes, including its Hydrosize and Hydrosize Carbon fiber sizing solutions and its Unyte technologies for technical textiles, which are on display at CAMX 2022.

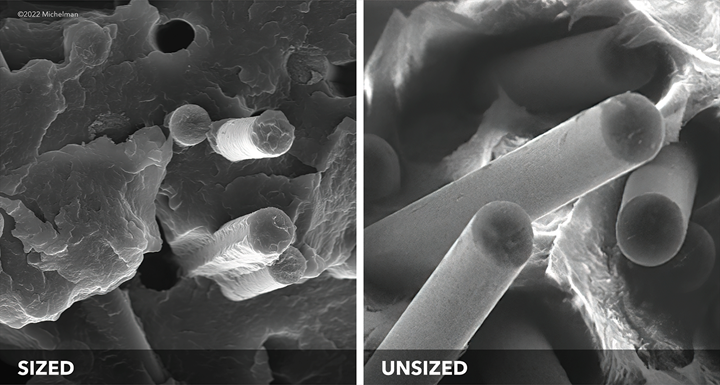

Hydrosize is Michelman’s flagship line of sizing solutions designed for use in the manufacturing of glass, basalt and natural fibers, including both chopped and continuous formats. They are used as lubricants, film formers, sizing agents and binders during fiber manufacturing and composites processing. This technology is said to enable fiber manufacturers to optimize the interfacial adhesion between the polymers and fibers by tailoring their reinforcement fibers’ surface chemistry to the matrix resin’s chemistry. This improved interface adhesion helps fiber producers and composite manufacturers produce stronger, lighter and more durable composite parts. according to Michelman.

Michelman also features the line of Hydrosize Carbon solutions to produce higher quality carbon fiber parts. Michelman says it also helps further exploit the traditional benefits of composites — design freedom, consolidation of parts and integration of functionality while meeting lightweighting initiatives. Composites that require high-temperature processing typically require the use of high-temperature polyamide, polyimide, PPS and PAEK-based resins.

Select Hydrosize Carbon grades reportedly provide excellent thermal stability and are specifically designed to withstand elevated processing and subsequent applications. Furthermore, the various series of grades offer a wide variety of solutions depending on resin compatibility, fiber type and desired composite performance.

The company’s Unyte brand is a versatile family of water-based technologies that help achieve advanced form and function in woven and nonwoven materials used in the design of technical textiles and prepreg fabrics. These solutions enhance textile products’ performance by improving adhesion, binding, processability, and chemical and heat resistance. The Unyte Bind series offers multiple solutions that improve fiber-to-fiber adhesion, Michelman says. Unyte Grip promotes the adhesion between fibers and polymeric matrices, helping to improve various functional or mechanical properties. Unyte Slip is beneficial for fabrics, nonwovens and prepregs that need to be stacked or rolled without sticking together. Finally, Unyte Resist products are designed to provide improved wetout and moisture/chemical resistance to fabrics. They impart performance benefits, including chemical resistance, water resistance and hydrophobicity under humid conditions to fabrics, wovens and nonwovens.

Related Content

-

Recycled carbon veil designed to close carbon fiber lifecycle loop

CAMX 2023: Technical Fibre Products’ new nonwoven veil can be reused in composites, effectively closing the loop and providing a viable route for the recycling of fibers.

-

Winding software developed for filament winding machines

CAMX 2023: Roth Composite Machinery focuses on automation, safety and time savings.

-

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.