Industrial, high-performance equipment advances composites processing

JEC World 2024: Modular, multi-stage ThermoPress double-belt presses, ScatterPro precision scattering and film casting with high-precision Venturi drying are key highlights at IPCO’s booth.

IPCO (Baden-Württemberg, Germany), a manufacturer of processing systems for composite materials, is using JEC World 2024 to highlight the scope and capabilities of its ThermoPress double-belt press systems, ScatterPro precision scattering lines and continuous film casting process.

The company is a globally active engineering group, manufacturing and installing process systems for the production of a wide range of composite materials used in the automotive, aerospace, flooring, construction, nonwoven and textile industries.

IPCO supplies double-belt press systems based on steel belts, polytetrafluorethylene (PTFE) belts or a combination of the two. Pilot systems based on all three types — an IPCO ThermoPress SB high-pressure line using IPCO steels, a ThermoPress TB low-pressure line based on PTFE belts and ThermoPress CB CombiBelt unit — are available for product trials and assessment at the company’s 1,600-square-meter Productivity Center near Stuttgart, Germany.

In particular, IPCO points to its steel belts, which it says were first manufactured in 1901. These belts are used in applications ranging from conveying and cooling to heating and pressing; their main applications in composite processing are in high-pressure ThermoPress SB systems used in the production of thermoset/thermoplastic composite materials, and hybrid ThermoPress CB CombiBelt lines, where they are used to create high pressure modules within the forming zone of PTFE belt-based double-belt presses

The modular design of the company’s ThermoPress systems enables multiple stages of production — including polymerization, curing and cooling — to be incorporated into a single process. A choice of belt types and pressure modules allows systems to be configured to meet virtually any pressure and heating requirements.

A full range of processes can be assessed at IPCO’s test facility, from pressing, lamination and impregnation, to cooling and tempering. Applications include consolidation of pre-laminated sheets and impregnation of fibers with resin. Resin can also be applied in powder, film or liquid form onto a nonwoven or felt material.

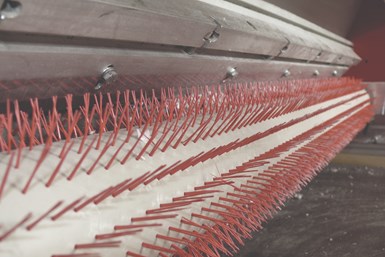

Complementing the ThermoPress range, IPCO manufacturers a range of high-precision scattering systems that can be incorporated into production lines to scatter powder, granulate or fibers onto a carrier material before being formed by pressure and/or heat.

The ScatterPro P model, for example, is a powder scattering unit used in the production of flooring, filters, electronics, smart chips and more. The ScatterPro F enables uniform scattering of fibrous materials used in the manufacture of products for the automotive, textile, recycling and construction industries. A modular design enables multiple stages to be incorporated into one continuous process.

IPCO is also showcasing the benefits of its continuous film casting units and Venturi drying systems. The quality of films produced using this process makes them ideally suited for use as separator membranes and ceramic tapes in energy storage applications.

The three main components of the system are a precision slot die, a polished steel belt and the Venturi dryer. The slot die coater delivers a uniform casting of the product onto a moving steel belt. The film is carried to the Venturi dryer, a technology reported to be unique to IPCO for this application and one that eliminates any risk of skin formation on the product.

Visit IPCO at Booth D90 in Hall 6.

Related Content

JEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

Read MoreJEC World 2023 preview

JEC World is the composites industry’s largest trade event, featuring exhibits, presentations and specialized pavilions covering the entire composites industry supply chain.

Read MoreJEC World 2024 preview

The world’s largest composites industry trade event returns to Paris, France, March 5-7, 2024, featuring exhibits, awards, conference programming and more.

Read MoreJEC announces 11 Innovation Award winners

The JEC Group has announced the winner for each of the 11 Innovation Award categories. Learn more about the winners and their projects at JEC World 2024.

Read MoreRead Next

BriskHeat celebrates 75 years in the industrial heating industry

Founded in 1949, BriskHeat has evolved to serve customers globally, providing flexible surface and immersion heating products, controllers and insulators.

Read MoreIPCO introduces powder, fiber scattering system

The company’s double-belt presses and scattering systems provide an efficient solution for the continuous production of a range of materials.

Read MoreAZL to carry out ultra-fast consolidator machine and inductive double-belt press developments

Innovative systems demonstrate highly scalable and flexible consolidation of composite laminates. Follow-up projects to be carried out this year.

Read More