Intelligence-based design, advanced simulation capabilities added to Siemens NX software

Part of the company’s Xcelerator portfolio, Siemens NX has been revamped for design, topology, lattice and orientation optimization as well as enhanced AI and ML functionality.

Siemens Digital Industries Software (Plano, Texas, U.S.) has launched the latest release of its Siemens’ NX CAD/CAM/CAE software, part of the Xcelerator portfolio of software and services. The latest release of NX software adds in advanced technologies, such as artificial intelligence (AI) and advanced simulation capabilities, while continuing to invest in productivity and capability enhancements.

Leveraging its convergent modeling and automated model-based definition authoring for PMI generation together with task-based collaboration, Siemens’ latest software revision weaves together topology optimization design from requirements, through to component generation, additive manufacturing (AM) and final machining.

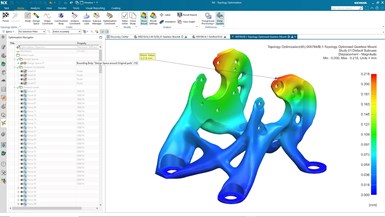

The evolution of integrated analysis with design enables engineers to do first pass analysis and optimization of product performance. Photo Credit: Siemens Digital Industries Software

The new NX Topology Optimizer, for example, helps to create parts based purely on functional and design space requirements, resulting in fully editable convergent bodies. Inevitable design changes can be quickly made, and optimizations and any downstream features updated automatically.

The Design Space Explorer combines design space exploration with generative engineering to help designers automatically optimize a design against multiple objectives. Design engineers define the optimization problem with all parameters, constraints and objectives in place and NX uses Simcenter HEEDS software to conduct multi-objective parameter optimization, providing the designer an immediate set of viable design alternatives to consider.

Another feature, increased artificial intelligence (AI) and machine learning (ML) in the Selection Prediction and Select Similar commands uses shape recognition to quickly identify geometrically similar components, while the NX Voice Command Assist enables the user to invoke commands, navigate multi-level menus and operations as well as teach the system words or phrases to carry out common tasks. Ask NX “Have we done something like this before?” and it will carry out a Shape Search using Siemens’ Geolus technology.

According to Siemens, lattice structures within NX can now be optimized using Siemens’ Simcenter 3D simulation to derive the optimal lattice structure in a singular environment, reportedly eliminating the multiple design analysis steps traditionally required. Elsewhere, Part Orientation Optimization brings nesting of parts (and their associated supports) within a machine build area along with integrated cloud-based orientation optimization processes to find the optimal build orientation for reduced thermal distortion.

Related Content

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

ATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.