Multi-walled carbon nanotubes available in three forms

Goodfellow’s multi-walled carbon nanotubes are available as regular powder, “chunky” powder or free-standing “carpets.”

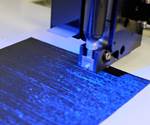

Goodfellow’s (Coraopolis, Pa., U.S.) multi-walled carbon nanotubes (MWCNTs) are available in three different forms: regular powder, “chunky” powder and free-standing “carpets.” All three forms are produced by means of a catalytic chemical vapor deposition (CCVD) process.

Regular powder is available in research quantities of several grams up to economical mass production quantities of several kilos.

What the company calls “chunky” powder, exclusive to Goodfellow, is said to be safer and easily dispersed via sonication into a polymer matrix. It is available in small quantities for research.

Free-standing, vertically aligned MWCNTs arrays, called “carpets” or “forests” — also exclusive to Goodfellow — are distinguished by their anisotropic properties. According to the company, current research revolves around potential uses as free-standing membranes and filters, thermal interface materials, in electronic devices and supercapacitors, and by embedding them in polymer matrices for the production of innovative composites. MWCNTs “carpets” are available in small quantities for research.

Carbon nanotubes are tube-shaped materials composed of carbon atoms covalently bonded in hexagonal network, having a nanometric diameter. As an additive in composites, they can improve the mechanical, thermal or electrical properties of a material, offering benefits such as high electrical conductivity, good processability, flame retardancy, thermal dissipation, UV resistance and more. Industries where these attributes are especially beneficial include aerospace, automotive, electronics, energy, oil and gas, coatings and sporting goods.

Related Content

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

.jpg;width=70;height=70;mode=crop)