Search Results

Showing 201 – 210 of 1107 results

Composite materials are engineered combinations of two or more distinct materials, merging their individual properties to create a new material with enhanced characteristics. Typically composed of a reinforcing phase (like fibers or particles) embedded within a matrix (often a polymer, metal, or ceramic), composites leverage the strengths of each component to achieve superior strength, stiffness, lightness, or other desirable attributes. Their versatility extends across industries, from aerospace and automotive to construction and sports equipment, where their tailored design and exceptional properties offer solutions for high-performance applications.

Recycling in composites manufacturing is an evolving endeavor aimed at addressing sustainability challenges. Unlike traditional materials, composites often pose recycling complexities due to their multi-component nature. However, innovative techniques are emerging to tackle this issue. Methods like pyrolysis, mechanical recycling, and chemical processes are being developed to efficiently recover valuable components from composite waste, such as fibers or matrix materials.

Multi-year R&D at ThermoPlastic composites Applications Center (TPAC), TenCate and Clean Sky 2 demonstrate economic advantage of serial production using recycled materials.

While expected wind business revenue did not materialize for Q3 2024, Gurit is actively implementing measures to diversify its portfolio and position it for a wind sale increase in 2025.

Juc Surf uses 100% recycled carbon fiber scrap materials for a more sustainable surfboard that doesn’t sacrifice performance.

New agreement with Trillium Renewable Chemicals will enable Solvay's development of sustainable, bio-carbon fiber for use in various applications.

SPE shares highlights, award recipients, exhibitors, speakers and more from its 2024 Automotive Composites Conference & Expo (ACCE).

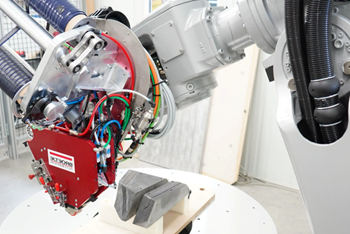

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

New grades include low-warpage and hydrolysis-resistant glass fiber-reinforced grades, with post-consumer chemical- and material-recycled versions in development.

When used with composite reinforcements, EzCiclo can be recycled and degraded via the company’s CleaVER recycling technology with waste elimination and a final fiber with equivalent virgin fiber mechanical performance.

With fiber weight fractions of up to 50% and an array of thermoplastic matrices available, injection molding compounds are expanding composites’ capabilities.

The newly formed enterprise is part of Deakin’s “Recycling and Renewable Energy Commercialisation Hub” (REACH). Feedstock will be processed from a variety of waste streams throughout Australia.