Recycled thermoplastic composites for production

Multi-year R&D at ThermoPlastic composites Applications Center (TPAC), TenCate and Clean Sky 2 demonstrate economic advantage of serial production using recycled materials.

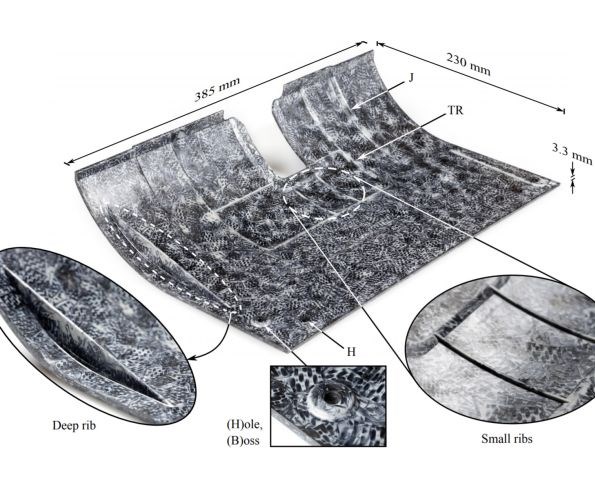

Recyclability has been a long-promised benefit of using thermoplastic composites (TPCs). But it has yet to be used commercially on a large scale. Materials supplier TenCate Advanced Composites and the ThermoPlastic composites Research Center (TPRC) partnered with Tier 1 manufacturer GKN Fokker to demonstrate such a process in 2016. The team developed an access door panel using scrap TenCate Cetex TC1100 woven carbon fiber/polyphenylene sulfide (CF/PPS) material from GKN Fokker’s production of the Gulfstream G650 elevator and rudder. The production waste was chopped and then compression molded using a process and mold designed by TPRC. The access door panel featured molded stiffening ribs, thickness variations and molded-in holes with bosses. (A boss is a protruding feature that guides a fastener into the hole). Use of the reclaimed material enabled a lightweight part with greater molded-in functionality while forming a closed-loop manufacturing process, as the access door panel was then used on the leading edge of the Gulfstream G650 rudder. The project won a JEC Innovation Award in 2016.

Access door panel demonstrated in 2016 is made from scrap Cetex CF/PPS material and features stiffening ribs and molded-in holes with bosses. SOURCE | TPRC.

Since that research, a new organization has been established, the ThermoPlastic composites Applications Center (TPAC). “The TPRC was formed ten years ago and works mostly in fundamental TPC research for the aerospace industry,” explains Thomas de Bruijn, a researcher in lightweight structures at TPAC. “The TPAC was formed roughly two years ago, and has a more applied way of working. It is linked to Saxion University and also with SMEs. We focus on bringing costs down by developing more cost-effective processes. Together, these two groups form TPC NL, a smart industry, digital innovation hub for TPC technology.”

The involvement of the TPAC and also TenCate’s continued R&D have demonstrated that this type of closed-loop manufacturing is not only possible, but economically beneficial. Focus, initially, is on CF/PPS materials, and research is in collaboration with industry partners to help implement this TPC recycling-enhanced parts production.

However, the actual processes developed differ. TenCate has focused on shorter fiber material used as a flow layer to add molded geometric features and functionality to continuous fiber parts. Meanwhile, TPRC and TPAC have sought to maintain greater fiber length, creating a dough-like material that can be compression molded into parts with higher mechanical properties than possible with traditional short-fiber compounds.

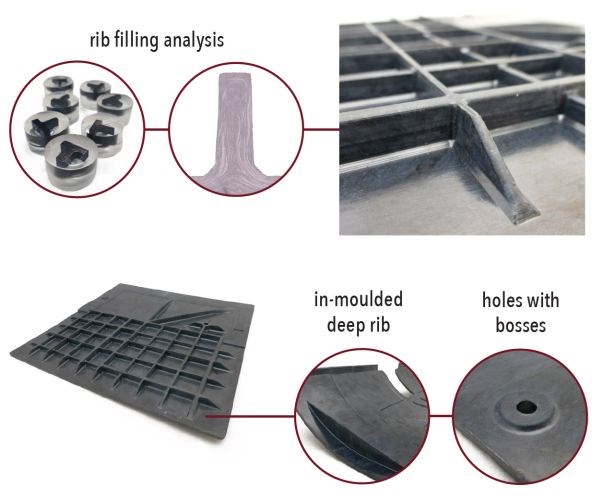

TenCate — Flow layer enhanced organosheet parts

“Three years ago, we started investing more of our R&D budget into recycling,” says Frank ten Napel, TenCate product manager for thermoplastics. “This is not just to get a ‘green label’. We are convinced that incorporating recycled material into your part offers very real economic and construction benefits. We can apply a level of geometry to a part that we could not achieve otherwise. By applying a flow layer of recycled material, we can mold in stiffening ribs and variable thickness across the part, as well as bosses around holes, which spread loads induced by fasteners. All of this enables using less continuous fiber material, for thinner, lighter and more cost-effective parts versus just using virgin material.” He notes these molded features are difficult to achieve with continuous fiber materials, “but by combining both continuous fiber plus localized overmolding you get more freedom of design.”

Recycled TPC material can be used either as a core or surface flow layer.

SOURCE | TenCate

By using scrap from a program back into that same program, it is also possible to approach a 100% buy-to-fly ratio — i.e. zero waste. “This is ideal because there is a synchronized supply and demand,” says Ten Napel. “It also solves issues with traceability and purity of the reclaimed/recycled material.”

TenCate has completed a lot of basic process development and material characterization work, both on its own and in collaboration with TPRC and other partners. It has demonstrated process repeatability and established the fiber length necessary to achieve a balance between mechanical properties and good flow for molding complex geometries. “We shred the material into smaller chips than the process used by TPRC/TPAC,” explains Ten Napel, “this results in a high flow layer comprising high fiber volume, long fiber reinforced molding compound.” This can then be processed using conventional, short cycle time (e.g. 5-minute) stampforming in a compression molding press.

This bracket-type demonstrator shows both sides of the same part, highlighting a conventional woven organosheet layer and recycled TPC flow layer. The latter features stiffening ribs and bosses for inserts. SOURCE | TenCate

TPC-Cycle Project

This four-year project began in September 2015 and includes partners from throughout the thermoplastic composite (TPC) supply chain:

- TenCate Advanced Composites (Toray Group) – materials

- GKN Fokker Aerostructures – Tier 1 design and manufacturing of aerospace structures and assemblies

- Dutch Thermoplastic Components (DTC) – SME design and manufacturing of aerospace ribs, stringers, brackets, clips, boxes

- Cato Composites – SME manufacturing and design of parts for aero, auto, defense, sports and consumer markets

- Nido RecyclingTechniek (NRT) – technology for shredding and reducing size of materials/parts to be recycled

TPC-Cycle is facilitated by TPAC and Saxion University of Applied Sciences, particularly its lightweight structures research group, and funded by Regieorgaan SIA, part of The Netherlands Organization for Scientific Research (NWO).

Thomas de Bruijn is TPC-Cycle project manager and a researcher in lightweight structures at Saxion/TPAC. He explains there were many drivers for starting the TPC-Cycle project. “We could see an increase in the use of continuous fiber TPCs, especially for stamp-forming, as in clips and brackets. With this increase, the volume of post-industrial waste becomes substantial. So, recycling was necessary, both for the environment and economically, and also to meet regulations. For example, European end of life legislation demands that 95% of the material used in automobiles be recycled.” He notes that Airbus too has set recycling and end of life goals, and has communicated these to their suppliers. “The supply chain should not only say they can meet these goals, but also prove that capability with demonstrators,” de Bruijn adds.

“We have also seen TPCs growing outside of aerospace, in applications like food crates, furniture and industrial components because they offer lower cycle times, lightweight and smarter structures,” says de Bruijn.

He continues, “We wanted to prove out a commercially viable recycling process chain but not just grinding, which is downcycling. We wanted high performance. So, we chose a low-shear mixing approach to retain 0.5-1.0-inch fiber length. For stiffness, you only need a couple of mm length. But for strength and impact resistance, you need more than 0.5-inch length.” In addition to maintaining fiber length, another key challenge was to get good homogeneity in mixing the materials and in the final recycled product.

“The goal is to collect waste, shred it to 0.5-1.0 inch flakes and transform it into a homogeneous dough, which is extruded and directly transferred to a compression molding press,” explains TPRC researcher and Ph.D. student Guillaume Vincent. “The processing of the dough is done via feeding flakes and virgin polymer granules into a low-shear mixer, reducing the fiber weight fraction to 25-40%.” He notes the process is very similar to direct compounding of long fiber thermoplastics (D-LFT), which is common in automotive. “However, D-LFT processes require millions of dollars of investment, so they are only used in high-series production. We have modified our approach by using smaller machines yet we get similar results. Our volumes are low vs. D-LFT processes.”

Vincent describes an example of where including the complete recycling value chain pays off: “NRT helped connect us with manufacturers of larger shredding machines, such as Untha.” This is a key part of scaling the process for serial parts production.

The first process chain being developed is for CF/PPS. Vincent says TPC-Cycle has built simulation models and analysis methods to characterize fiber length and fiber distribution in the recycled material. “We are also understanding how these material characteristics transfer to the properties of the molded part,” he observes. This is, in fact, the focus of his Ph.D. thesis, which will be published by the end of 2019.

The TPC-Cycled project has developed a complete process chain for recycling thermoplastic composites, including cost-effective shredding and characterization of fiber length and distribution. SOURCE | TPRC/TPAC.

This recycled dough is sometimes referred to as bulk molding compound (BMC). Historically, BMC was a dough-like mixture of short glass fiber (<25mm), thermoset resin paste and fillers that was compression molded into composite parts. With less fiber volume and more flow versus sheet molding compound (SMC), it also offered slightly lower mechanical properties. TenCate has sold thermoset and thermoplastic BMC for years, though the latter is a process where chopped unidirectional prepreg tapes are spread into a mold and pressed. “Our product is actually quite different,” Vincent asserts. “With conventional thermoplastic BMC there is generally no mixing and requires a long heating and consolidation cycle. We found that with mixing you get a more homogeneous product and less stress concentrations in the part, so higher properties. With conventional thermoplastic BMC, you get thicker flakes that have matrix-rich regions at the ends which produce stress concentrations in the composite laminate.”

The low-shear mixing process disentangles the flakes into layers and then separates the layers into bundles and the bundles into loose fibers. Polymer is also mixed in to decrease fiber content in order to get better flow properties, so that the material is easier to process into shapes.

SOURCE | TPRC/TPAC

“The dough is extruded and then robotically placed into an open, isothermal [heated] compression mold,” explains de Bruijn. “After mixing, the fibers in the dough are randomly oriented. But during pressing, the flow of material re-orients the fibers. This orientation is less compared to mixtures using shorter fibers that are injection molded, but it’s similar from part to part. This is one of our topics of continued study.”

Cost

The TPC-Cycle process chain developed to date appears economically beneficial. “We hope to answer how much we can lower part costs by later in 2019,” says de Bruijn. “But this is complex because you need a market and have to sell the recycled material.” He notes there are many economic factors. For example, most manufacturers today are simply throwing production waste away. Local cost to dispose in landfill is €80 per ton ($90). “But this material being thrown away has value,” says de Bruijn. “Also, you must account for the costs to collect the waste, shred it, mix and then compression mold into new parts. However, this is also a near net-shape process with short cycle times due to the isothermal mold.” In other words, there should be a drastic reduction or elimination of secondary finishing and machining. De Bruin says TPC-Cycle is now looking into completing cost analysis and life cycle analysis.

SOURCE | TPRC/TPAC

Clean Sky RESET

A third project which reiterates the importance of the work completed by TenCate and also in the TPC-Cycle project is the RESET project, which ran from January 2016 until December 2017 and was coordinated by the Leitat Technological Institute in Barcelona, Spain. It appears that RESET was begun under Clean Sky (2008-2016) and completed during Clean Sky 2 (2017-2021).

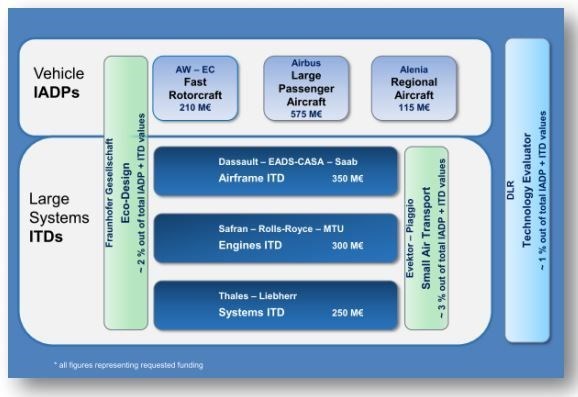

The Clean Sky and Clean Sky 2 programs are organized into a top tier of Innovative Aircraft Demonstration Programs (see Vehicle IADPs in the image below) and a lower tier of Innovative Technology Demonstrators (see Large System ITDs in the image below). RESET was completed as part of the Airframe ITD, specifically Work Package (WP) A-3.4 Eco-Design for Airframe.

SOURCE: Clean Sky 2 Joint Technical Proposal

For more details, see “Thermoplastic composite demonstrators — EU roadmap for future airframes”

According to Clean Sky project officer, Elena Pedone, the RESET team at Leitat developed a process to recycle previously used aircraft composite material and use that to manufacture new parts. They compared these recycled parts to those made commercially and found them to have similar mechanical characteristics. “The technology developed in this project could be realistically commercialized in the aeronautic sector in the next few years and possibly spill over to other economic sectors,” says Pedone.

During the RESET project, work was completed to investigate effects from PEEK and PPS thermoplastic matrix materials and the chemical nature of carbon fiber reinforcement. The reinforcement shape was studied, including fiber length and woven versus nonwoven. The effect of fiber content (polymer to fiber ratio) was also studied.

In a second work package, the main objective was the conditioning and characterization of recycled CF/PPS based on extrusion and the resulting molded composites. Two parts — a thermoplastic bracket and a thermoplastic cleat — were created by injection molding and another two by thermoforming, explains Leitat’s scientific coordinator of the project Claudia Aguilar. These parts were then tested. “The mechanical properties of the material were found to be comparable with the commercial counterpart,” says Aguilar.

The RESET project claims to have demonstrated a recycling process that can take TPC waste material from aircraft production and use it as raw material to produce new parts for aircraft. “Up to 70% of recycled material was used to produce a new family of composite materials,” says Aguilar. She adds that ”the recycling process of RESET allows European aviation to limit the environmental footprint and to reduce production costs of new aircraft parts. Hence, the project makes the aviation industry more competitive and greener.”

Bracket (left) and cleat (right) made from recycled CF/PPS material demonstrated by the Clean Sky RESET project. SOURCE | Leitat Technological Institute

TPC future starts with design

The assertion by TenCate and TPRC/TPAC is that these recycling processes that have now been demonstrated are not just green, but economically attractive. So, what kind of investment is required? “It depends on the production volume,” says Ten Napel at TenCate. “The shredding machines needed are not large or expensive and the process has been developed to where it is fairly straightforward.” Does matrix type affect recyclability? “No,” says Ten Napel, “but in terms of economic viability, carbon fiber and PPS, PEEK or PEKK are more viable than glass fiber and polypropylene because of their higher value versus the latter.”

“I think if this is going be taken up by the industry, it should start with design,” he continues. “The biggest hurdle right now is the mindset of engineers. To actually go out and design with recycled material (or design these partially into a new product) is pretty new to them.”

Ten Napel concedes that TenCate neither designs nor manufactures parts commercially, “but we are trying to inspire designers to think this way in developing their new parts and structures.” He cites aircraft interiors and access panels and access doors as low-hanging fruit for re-using recycled material. “If we as an industry can get used to reusing our own scrap and waste, then we can take the next step and begin looking at how to address end of life parts.”

The mantra on recycling thermoplastic composites—simply grinding and remolding— can definitely be adopted, says Ten Napel, but it often does not make a lot of sense economically. “We have demonstrated a better process and one that can actually create more cost-effective parts and overall programs. We have chosen to disseminate this knowledge, along with the TPRC and TPAC, in order to inspire the industry as to what is fully possible with thermoplastic composites.” If thermoplastic composites are to be adopted on a grand scale, recycling as an inherent part of production is no longer an option, it is a necessity.

Related Content

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreComposites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreRead Next

Thermosets vs. thermoplastics: Is the battle over?

Dale Brosius, the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI) and a regular CW columnist, sees a shift in the industry from infighting between proponents of thermoset and thermoplastic composites to a healthier competitive atmosphere that serves to make composites overall more competitive with legacy materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More