Search Results

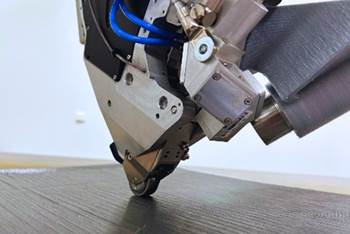

Showing 41 – 50 of 449 resultsTo meet sustainability targets and market demands, the aerospace industry is searching for alternative joining methods. Automated assembly of thermoplastic composite structures by induction welding offers a solution. (Sponsored)

Flexible welding cell developed for coupon welding to facilitate process qualification of KVE INDUCT welding technology for thermoplastic composites.

Part of $100 million, five-year investment to advance, qualify thermoplastic composites for military and commercial aero applications.

Attend this May 18th interactive webinar sponsored by Altair, Mitsubishi Chemical Group, Toray and Collins Aerospace which will explore the materials and processing technologies that are enabling the transition into thermoplastics.

A recent study conducted on vacuum-infused thermoplastic fiber-metal laminates has highlighted the performance benefits behind using TFP’s nonwovens for consistent, uniform bondlines and interfacial bonding.

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

This compact cell brings together 3D printing, AFP and milling aided by a comprehensive software program, further simplifying the manufacture of complex thermoplastic composite aerostructures in the future.

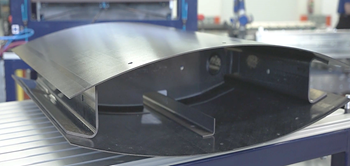

Collins Aerospace in Almere has produced a 7-meter raceway for the Clean Sky 2 MFFD lower fuselage using novel CCM and tooling technology while the Riverside facility in the U.S. advances AFP and welding as part of global strategy for more sustainable airframes.

Clean Sky project has delivered the 8 × 4 meter welded aerostructure component, aided by advanced thermoplastic composite technologies and smart robotics.

The aerospace group joins as part of the ongoing initiative to decarbonize aviation. Safran believes thermoplastic technology development acceleration is a key target to meet this goal.