Search Results

Showing 51 – 60 of 449 results

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

Carbon/PEKK floor beams prove production worthiness of lower cost, fast coconsolidation process.

Newly launched program in the Netherlands will run until 2030 with more than 330 partners contributing knowledge to advancing high-tech solutions, including additional research in composites welding, recycling and AFP.

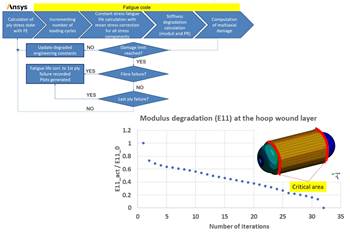

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.

Major aerospace supplier commits resources to scale rate-enabling manufacturing processes for Supernal’s SA-A1 CFRTP component assembly.

With fiber weight fractions of up to 50% and an array of thermoplastic matrices available, injection molding compounds are expanding composites’ capabilities.

Spinning off from a German Aerospace Center (DLR) research project, msquare GmbH’s technology aims to innovate and enable repair for high-temperature thermoplastics.

The Sunburst portfolio of thermoplastic-bonded abrasives enables the deburring, cleaning, finishing and polishing of metals, plastics, composites and more.

The FlatJet Welder, designed for thermoplastic components of all sizes, blasts a thin, directed jet of uniform, high-temperature air/gas for a fast, full-surface melt.