Aerospace

Research on OOA processing continues

Much work has been done to make OOA processing practical for aerospace applications, but much work still remains if it is to become the compelling option.

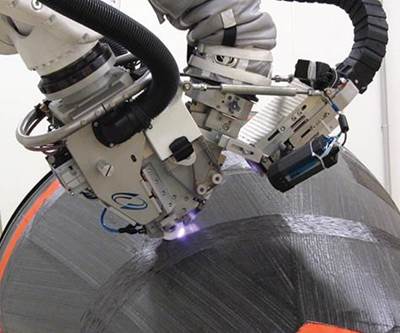

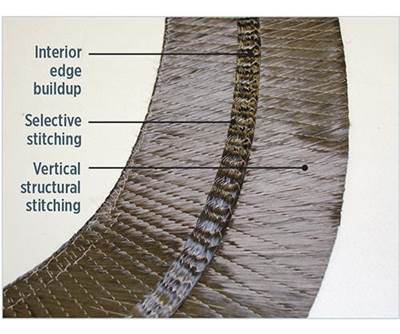

Read MoreDry fiber placement: Surpassing limits

Coriolis Composites’ automated aerostructures manufacturing using dry materials moves from development projects to production.

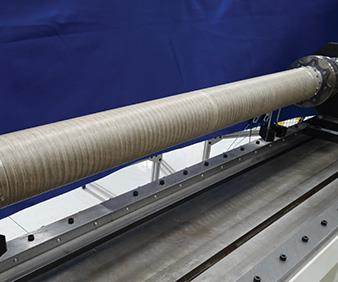

Read MoreOOA: Thermoplastic alternative targets performance spec

CF/PEEK helicopter driveshaft’s toughness trumps traditional metric.

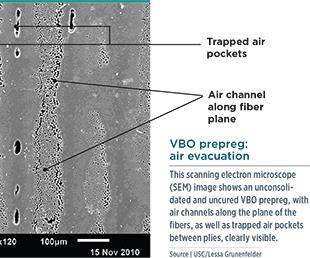

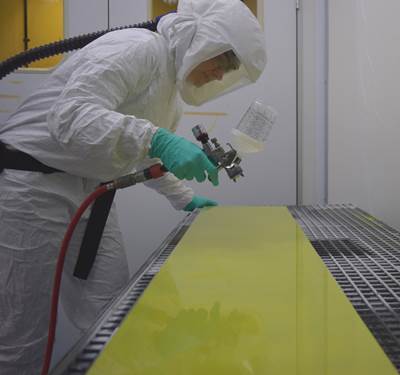

Read MoreVBO prepregs: The Vision SF50

OOA vacuum-bag-only process makes carbon fiber structures a reality for the world’s first personal jet.

Read MoreResin transfer molding: An update

Fulfilling the promise of OOA composites without sacrificing pressure.

Read MoreResin infusion: Taking off?

Boeing Aerostructures Australia leads large-scale development of resin infusion as an industrial process.

Read MoreOOA overview: Market & opportunities

CW looks at where aero-OEMs and their suppliers are finding out-of-autoclave alternatives.

Read MoreSafran plans to locate third Safran/Albany composites facility in Mexico

The new plant, in Querétaro, Mexico, will mirror those in New Hampshire and France, producing carbon fiber fan blades for CFM International's LEAP engine.

Read MoreGKN Aerospace, Durham University developing process to measure aircraft wing drag reduction

Project aims to identify GKN Aerospace-developed surface technologies that reduce drag by 25%.

Read MoreComposites manufacturing from a different angle

A bunch of really smart engineers showed up in Long Beach, CA, US this week for the Society of Manufacturing Engineers’ (SME, Dearborn, MI, US) AeroDef conference and exhibition. All were focused on looking at ways to manufacture products — composite or not — more efficiently.

Read More