ATL/AFP

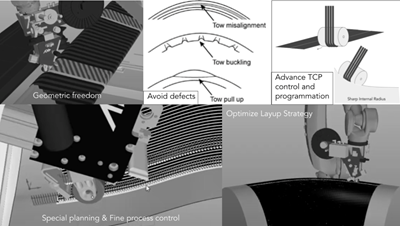

Addcomposites path-planning, simulation and defect detection platform for AFP

Purpose-built OLP software platform, AddPath, now supports multiple AFP tools, enabling end users to use their own existing hardware.

Read MoreAFP-XS platform demonstrates rectangular tube manufacture

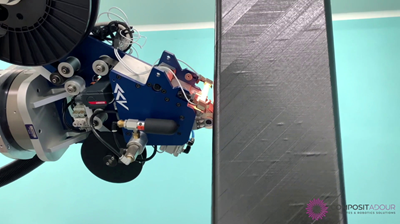

Addcomposites collaborated with MBDA and Compositadour to produce lightweight, stiff and weatherproof components that are electrically insulating, chemically resistant and dimensionally stable.

WatchAddcomposites brings multi-tow AFP system to the composites market

The automated system offered by Addcomposites is adaptable to complex shapes and enables multi-format and multi-material type preforming.

Read MoreMiddle River Aerostructure Systems displays aeroengine nacelle using AFP and RTM composites

Highlights technologies and manufacturing processes that enhance aeroengine operating efficiency while reducing fuel consumption and noise.

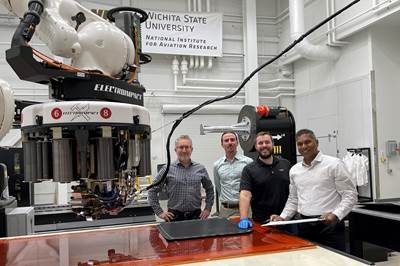

Read MoreNIAR-WSU, Victrex begin NCAMP materials and process qualification for AFP

In-depth investigation into AFP machine variability on composite allowables begins on carbon fiber-reinforced thermoplastic (CFRTP) test panels to achieve certification framework.

Read MoreQuiet supersonic demonstrator X-59 begins ground testing in Texas

Critical testing ensure the composite aircraft can withstand the loads and stresses that typically occur during supersonic flight.

Read MoreAddcomposites AFPnext program grows digital automation capabilities for composites manufacturing

AFPnext aims to increase access to advanced composites manufacturing by eliminating key risks to manufacturers.

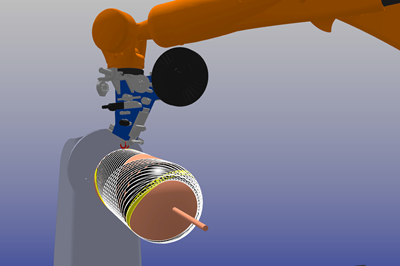

Read MoreAddcomposites adds tape winding to Finland facility for pilot trials

The new capability, which enhances the available level of design freedom, was added to encourage manufacturers to develop new innovations using tape winding.

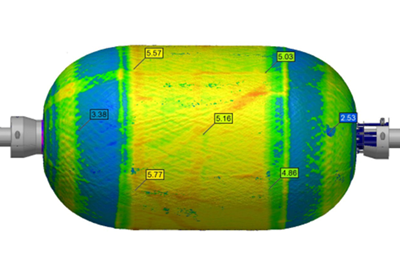

WatchNCC’s all-composite Type V tank demonstrates future composite space tank technology

SpaceTank project delivers a 96-liter carbon fiber composite tank with 4.0-5.50-millimeter nominal wall thickness for 30% weight savings in launch vehicle and satellite propellant tank applications.

Read MoreHengshen to produce rear pressure bulkhead demonstrators

China-based Hengshen Carbon and Composites will produce five 4.5-meter demonstrator composite rear pressure bulkheads (RPB) for a Chinese aerospace OEM.

Watch

.jpg;maxWidth=300;quality=90)