ATL/AFP

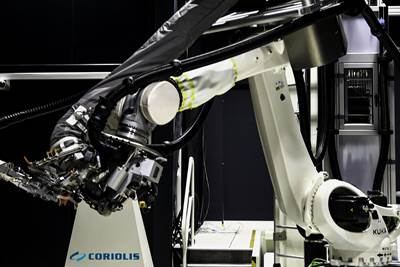

Cannon Tipos, Coriolis Composites mold complex automotive structural part from single preform

Dosing equipment for precise injection and mold engineering enable near-net-shape dry preform for HP-RTM CFRP composite part with rapid cycle time.

Read MoreCygnet Texkimp builds high-precision slitter spooler rewinder for industry trials

Demonstration machine can precisely slit and wind up to 48 tapes from continuous thermoset UD carbon fiber prepreg, with additional material compatibilities.

Read MoreDrawing design cues from nature: Designing for biomimetic composites, Part 1

Biomimicry is an interdisciplinary methodology that can inform composites design and manufacturing via use of more effective and sustainable materials, structural fabrication and technological practices.

Read MoreTri-Mack introduces thin, lightweight thermoplastic composite enclosures

Durable, low-cost manufacturing support wide range of industrial uses, with option for embedded EMI shielding.

Read MoreCollins Aerospace demonstrates new thermoplastic composites capabilities

Collins Aerospace in Almere has produced a 7-meter raceway for the Clean Sky 2 MFFD lower fuselage using novel CCM and tooling technology while the Riverside facility in the U.S. advances AFP and welding as part of global strategy for more sustainable airframes.

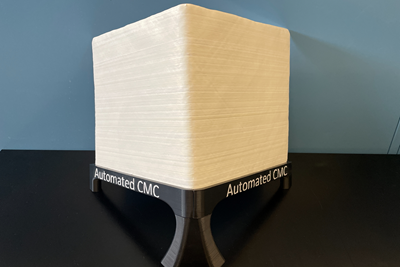

Read MoreNCC successfully demonstrates AFP manufacture of CMC parts

Core Research program adapts existing AFP technology and identifies optimal deposition parameters using a novel 3M towpreg material for wider CMC use.

Read MoreCAMX 2022 exhibit preview: Composite Automation

Composite Automation is joined by Isojet Equipements and PCM/Lucas Industries, bringing solutions for every step of the composites manufacturing process to one booth.

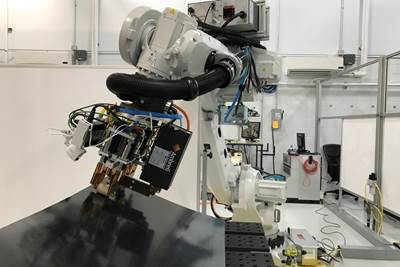

Read MoreCoriolis Composites installs AFP machine at Sabanci University

C1 robot contributes to technology development at the Integrated Manufacturing Technologies Research and Application Center (SU IMC) in Istanbul.

Read MoreCAMX 2022 exhibit preview: Qarbon Aerospace

Qarbon Aerospace exhibits its capabilities in manufacturing composite components and assemblies, highlighting its proficiencies in major assembly and systems integration, automated layup, hand layup, high-temp composites and core fabrication.

Read MoreProtecting EV motors more efficiently

Motors for electric vehicles are expected to benefit from Trelleborg’s thermoplastic composite rotor sleeve design, which advances materials and processes to produce a lightweight, energy-efficient component.

Read More

.jpg;maxWidth=300;quality=90)