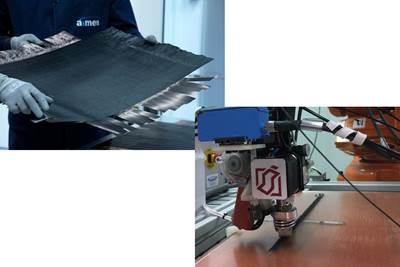

ATL/AFP

Rocket Lab unveils composite Neutron launch vehicle

Live streamed web event reveals detailed Neutron rocket architecture for the first time, including its carbon fiber launch vehicle and second stage, and new Archimedes rocket engine, all designed for reliability and reusability.

WatchFraunhofer IPT develops thermoplastic composites in hydrogen storage, engine blades and more

Active in laser-assisted tape winding and in-situ consolidation of thermoplastic composites since 1988, the IPT in Aachen, Germany continues to push new materials, applications and Composites 4.0 digital processing.

WatchClean Sky 2 FUSINBUL project develops full-scale, carbon fiber pressure bulkheads

Two 3.5-meter pressure bulkhead demonstrators incorporate advanced layup techniques with the goal of increasing serial production capabilities for fuselage manufacture for regional aircraft.

WatchDOMMINIO virtual workshop to explore multifunctional and intelligent composite airframe parts

Nov. 30, 2021 event for H2020 project will review latest advances in thermoplastic composites, additive manufacturing and digital manufacturing.

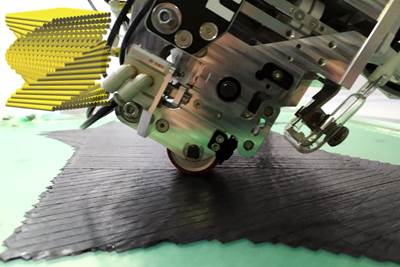

Read MoreConbility delivers Pre-Pro 3D tape winding head to Bilsing Automation

Multifunctional system will assist Bilsing’s manufacture of composite structures, particularly for the automotive industry.

Read MoreCreating stronger composites through nature-inspired, Helicoid designs

Helicoid Industries claims 50% increased toughness, impact strength and reduced material, weight and cost versus quasi-isotropic “fail-safe” designs.

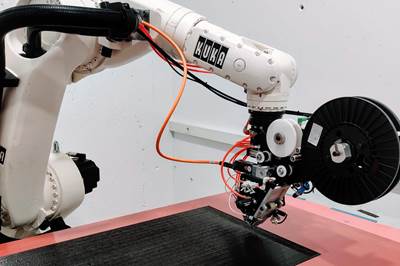

Read MoreCompoxi installation widens AFP-XS technology application domain

Compoxi aims to characterize and qualify the AFP-XS and new materials for adoption in the growing Space and New Space markets.

WatchComposites Evolution showcases high-performance prepregs, novel thermoplastic UD tapes

Composites Evolution highlights its Evopreg prepreg family, as well as PA6 tapes reinforced with UD carbon fiber for ATL, filament winding and compression molding.

Read MoreDesigning for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

Read MoreDLR Institute of Structures and Design increases maturity of thermoplastic composite fuselage structures

Project with Airbus demonstrates OOA co-consolidated stringer-stiffened skin with resistance welded frame and cleats.

Read More

.jpg;maxWidth=300;quality=90)