ATL/AFP

Broadband flash lamp heat source improves material deposition

CAMX 2023: Humm3 technology is a broadband flash lamp heat source for AFP, ATL, filament winding and more composite applications, delivering power previously only available from lasers.

Read MoreAFPT, Alformet advance bending of thermoplastic composite tubes

Specialists in AFP and LATW discuss process and lessons learned for new applications in CFRTP parts.

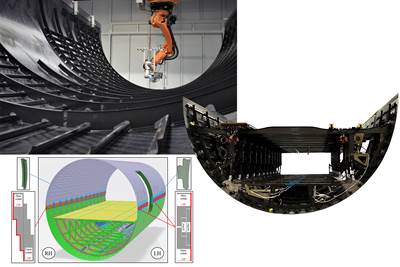

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreKanfit completes production of acceptance test part with AFP

The Ingersoll AFP machine is reported to be the first of its kind in Israel, aiding Kanfit’s R&D venture and strategy to adopt new technologies for composite production.

WatchAirborne delivers composite upper stage tank for EU ENVOL project

Nine-member consortium targets development of low-cost, green vertical orbital launcher with manufacture of an ultra-lightweight composite tank design in an automated manufacturing environment.

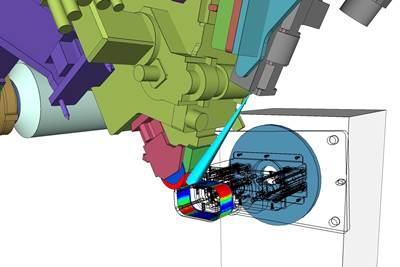

Read MoreHeat mapping simulation to improve AFP parts

An optical model developed for Coriolis Composites’ SimuReal AFP process simulation software enables verification of energy distributions during AFP to better define heating laws.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

Read MoreAdaptive composite elements for building facades exhibited at JEC World 2023

University of Stuttgart institutes use carbon and glass fiber composites, robotic fabrication, biomimetic design and digial twin/control to demonstrate adaptive facade elements for future buildings.

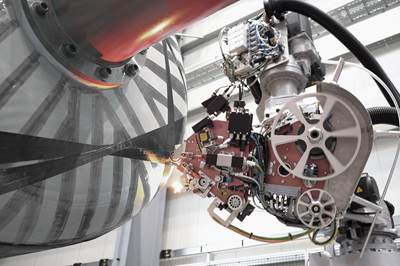

WatchJEC World 2023 preview: Broetje-Automation

The STAXX One automated fiber placement (AFP) systems are run by industrial robotics and incorporate digital twin technology.

Read More

.jpg;maxWidth=300;quality=90)