Design & Tooling

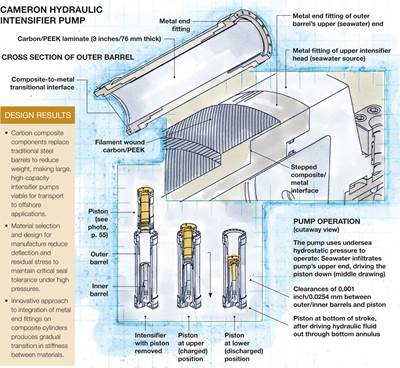

Carbon fiber/PEEK takes hydraulic pump to new depths

A switch from metal to composites reduces weight, minimizes part deflection in ultradeep ocean installations.

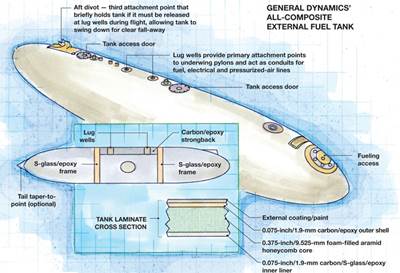

Read MoreCarrier-capable, all-composite external fuel tank

Legacy product positions builder for a shot at an F-35 contract.

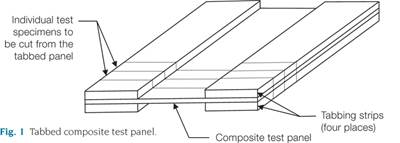

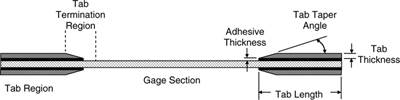

Read MoreTabbing composite test specimens: The how

The when and why of tabbing composite test specimens were the subjects of my previous column (see “Tabbng composite test specimens: When and why," under "Editor's Picks," at right), which included a discussion of tabbing materials, tab thickness and taper angle, and adhesive selection.

Read MoreSoftware eases design/build for exotic exercise bike

The Lamiflex Group (Bergamo, Italy) helps Milan, Italy-based design house Luca Schieppati develop the Ciclotte, a striking luxury exercise bicycle made with carbon fiber composites.

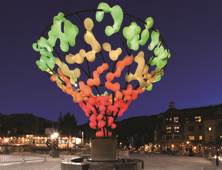

Read MoreWater tree: Single complex mold shapes unique composite sculpture

To fabricate a complex design for a lighted sculpture, sculptor Lawrence Argent taps the talents of composites specialists Kreysler and Assoc. (American Canyon, Calif.).

Read MoreTabbing composite test specimens: When and why

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) discusses when and why test specimens must be protected by tabs.

Read MoreProper mold care: Mandatory!

CT surveys mold care product suppliers for guidance through the critical steps of mold preparation and maintenance.

Read MoreLow-volume thermoplastics: Differential pressure molding

Cost-effective tooling and presses enable semi-automated prototyping and low-volume production of thermoplastic composites.

Read MoreDesigning bicycling’s lightest pro racing frame

Cervélo’s Vroomen White Design group combines analysis and manufacturing acumen to create a 675g/1.5 lb composite frame.

Read MoreCabin cruiser: Making the most of a mirror finish

The hull mirror-like gel coat finish on the Daedulus 30 cabin cruiser was achieved through a combination of Marine Concepts’ (Lee-on-the-Solent, Hampshire, U.K.) mold design experience and fabrication techniques and materials provided by Scott Bader (Wollaston, Northamptonshire, U.K.).

Read More

.jpg;maxWidth=300;quality=90)