Pressure Vessels

Wanted: Big thinkers and risk takers

Quickstep Composites (Dayton, Ohio) president and independent consultant Dale Brosius challenges the auto industry to think big and take risks in composites R&D.

Read MoreAdditives and modifiers: Matrix optimization

New and reengineered modifiers for thermosets and thermoplastics target previously elusive goals in composites processing and performance.

Read MoreModular design eases big wind blade build

First segmented composite blade increases power generation, eases installation and keeps weight and costs in check.

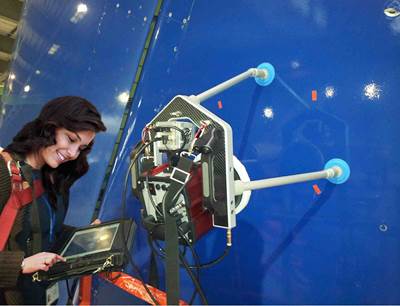

Read MoreBig blades, big innovations

In the process of designing its G128 wind turbine blade and the INNOBLADE segmented blade technology that simplifies its transport (see “Modular design eases big wind blade build,” under “Editor’s Picks,” at top right), Gamesa (Vizcaya, Spain) has introduced several innovative auxiliary technologies that reduce cost and simplify processing, particularly in the context of blade delivery and installation.

Read MoreIf not automotive then ... what?

CT columnist and president of Dayton, Ohio-based Quickstep Composites Dale Brosius says it’s not too early for composites industry operatives who are pursuing the automotive holy grail to begin exploration and market development elsewhere.

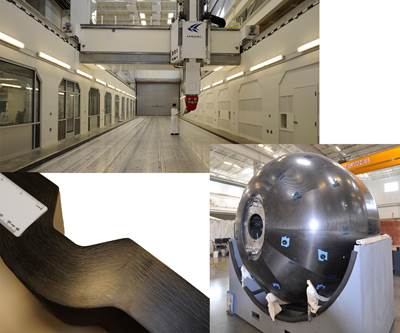

Read MoreBig machines, small tolerances

An examination of the lengths Janicki Industries (Sedro-Woolley, Wash.) goes to ensure dimensional precision in its massive CNC-machining operations.

Read MoreJanicki Industries: Breaking the mold

Once known only as a toolmaker, Janicki offers unique precision, production capability and problem solving as it pioneers leading-edge composites technology.

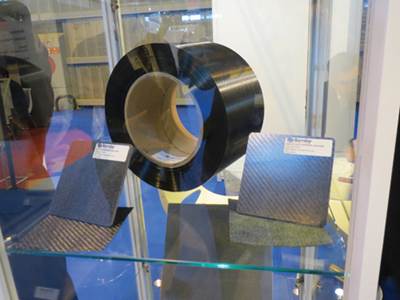

Read More2013 JEC Europe new product showcase

The JEC Europe 2013 trade show (March 12-14, at the Paris Expo, Porte de Versailles, Paris, France) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.

Read MoreSAMPE 2013 Long Beach new product showcase

The SAMPE 2013 trade show (May 6-9, in Long Beach, Calif.) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.

Read MoreJEC Europe 2013 review

Snow in Paris slowed traffic to the show floor but did nothing to cool the enthusiasm of composites innovators in a broad range of markets.

Read More

.jpg;maxWidth=300;quality=90)