Fabrics/Preforms

3-D preforms: Fast, efficient blade-root manufacture

To expedite the blade root manufacturing process for wind turbine blade manufacturers, 3TEX Inc. (Cary, N.C.) has developed RapidRoot, a 3-D preform.

Read MoreHeavy-duty infusion: Scaling up for scrubbers

Infused 3-D woven fabric preforms best steel in beams and unitized deck structures built for the caustic confines of massive flue gas desulfurization systems.

Read MorePortable wind turbine powers the warrior

DARPA-financed program puts wind energy to use for battery and system recharging.

Read MoreAntiballistics: Better defense, less expense

Armor applications grow on the strength of new markets, new composite materials.

Read MoreSpread-tow fabrics reduce waveboard weight

Fanatic (Molln, Austria) recently introduced a new version of its windsurfing waveboard, called FreeWave TeXtreme, made with TeXtreme spread carbon tow fabric from Oxeon AB (Boras, Sweden).

Read MoreSQRTM enables net-shape parts

New out-of-autoclave process combines resin transfer molding with prepregs for complex helicopter part prototype.

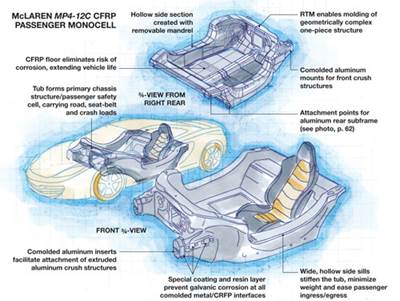

Read MoreF1-inspired MonoCell: Racing safety for the road

Resin transfer molding makes CFRP passenger cell mass-producible for new model supercar.

Read MoreStructural makeover: Big bridge-strengthening project

The 2.5-km/1.6-mile long cable-stayed-concrete West Gate Bridge in Melbourne, Australia, is prepped for added traffic lanes with BASF's MBrace composite reinforcements, pultruded by EPSILON Composite (Gaillan-en-Médoc, France).

Read MoreBoeing 787 Update

Approaching rollout and first flight, the 787 relies on innovations in composite materials and processes to hit its targets

Read More

.jpg;maxWidth=300;quality=90)