Materials

Pultruding polyurethane: Sheet pilings break boundaries

High-pressure pultrusion process creates polyurethane composite sheet pile system with the strength and stiffness to compete with steel.

Read MoreEvolution of tailored D-LFT

In the past two decades, two competing composite technologies — sheet-form glass-mat thermoplastic (GMT) and pelletized long-fiber thermoplastic (LFT) — led to the development of a new form of glass-reinforced thermoplastic composite.

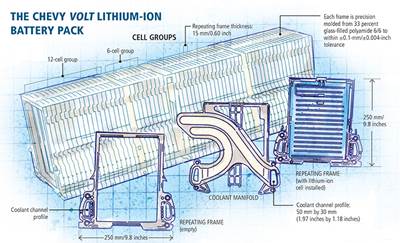

Read MoreChevy Volt battery pack: Rugged but precise

GM and partners engineer composites for this complex assembly with an accent on repeatability.

Read MoreJEC 2013 at first blush

CT Editor-in-chief Jeff Sloan risks some immediate reactions to his week in Paris at the JEC Europe 2013 composites trade show.

Read MoreSpace mission maximized via minimized survivability

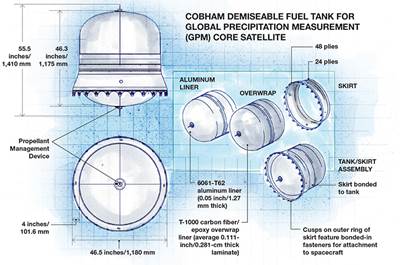

CFRP design and manufacturing flexibility prove key in first spacecraft fuel tank designed to disintegrate upon reentry for improved mission efficiency and debris mitigation.

Read MoreMarket Outlook: Surplus in carbon fiber's future?

Participants at CW’s Carbon Fiber 2012 Conference see one coming as early as 2016.

Read MoreFaster cycle, better surface: Out of the autoclave

GM is first automaker to use Class A CFRP parts from new pressure-press technology.

Read MoreMarket Outlook: Fiber-reinforced phenolics

When it comes to corrosion resistance and low smoke toxicity, it's hard to beat fiber-reinforced phenolics. Manufacturers look for new applications for this often overlooked material.

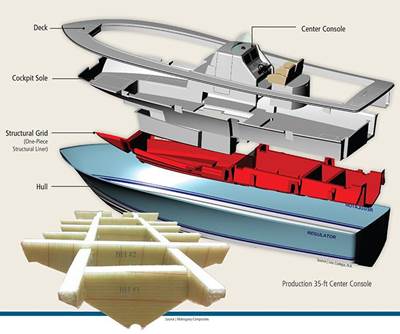

Read MoreThe structural grid: Prefabrication

Digitally designed and cut, preformed and preinfused stringers and bulkheads reduce boat weight, labor and cycle time and improve boatbuilder process control.

Read MorePaddleboard productivity: Adhesively bonded hull/deck is key

Dragonfly Boatworks LLC's (Vero Beach, Fla.) new standup paddleboard for fly fishing is built without fasteners, with the aid of SG200-40 methacrylate adhesive from SCIGRIP Smarter Adhesive Solutions (Durham, N.C.).

Read More