Underground storage tanks: Rehabilitation without excavation

An unusual “lost-core” composite adds double walls protection to noncompliant tanks without excavation.

The U.S. Environmental Protection Agency (EPA, Washington, D.C.) estimates that petroleum or other hazardous substances were stored in 587,000 underground storage tanks (USTs) in the U.S. as of March 2012. Because 51 percent of the U.S. population depends to some degree on groundwater for drinking water, the EPA established a UST regulatory program in 1984, aimed at eliminating the risk of groundwater contamination from leaks in these tanks. Federal UST regulations were amended in 1986 and 1988, becoming increasingly stringent. By 2005, they included requirements for secondary containment. The result was the double-walled tank. Similar to double-walled hulls in oil tankers, all new or replacement underground tanks now must have a secondary barrier and an interstitial void between the two walls. The latter enables interstitial monitoring, which uses sensors in the interstice to detect leaks of petroleum or contained chemicals through the tank’s inner wall and groundwater through the tank’s outer wall.

The EPA designed the UST program to be implemented by each state. However, the regulation landscape is complex, with some states allowing counties and municipalities to determine UST repair and replacement specifications. States have reported that UST releases are indeed the most common source of groundwater contamination, and petroleum is the most common stored pollutant. Most of the petroleum is in the form of gasoline and diesel fuel that is stored beneath retail gasoline stations.

State and municipal regulations may require a leaking single-walled tank to be excavated and completely replaced, or they may allow it to be repaired, inspected, certified and retrofitted for secondary containment. Leaking tanks in the latter category and still-serviceable single-wall tanks comprise a sizeable number of vessels that are in need of secondary containment. Thus, a variety of glass fiber composite systems have been developed to retrofit these existing tanks without excavation — with steel, polymer coatings or fiberglass composites — as an alternative to the high cost and downtime of complete tank replacement. These systems range from installing precured fiber-reinforced plastic (FRP) inner tank sections to a variety of methods for directly applying fiberglass and resin to the tank interior.

Delta Composite Systems LLC (Plymouth, N.H.) has developed its novel GENESIS interior secondary barrier system with ZPlex glass sandwich fabric by 3TEX (Cary, N.C.), which ensures not only containment and interstitial monitoring, but it also speeds up and improves the robustness of the application process and offers a quick and cost-effective way to cover the 700 to 800 ft2 (65 to 74m2) surface area in a typical tank. Significantly, when the GENESIS system is in place, it is — independent of the existing tank — a fully functional dual-walled fiberglass structure that could maintain compliant UST function regardless of any corrosion issues with the original external tank material.

Why retrofit?

According to Tony Rieck of T.R. Consulting Inc. (Colorado Springs, Colo.), a longtime consultant in this field, “roughly half of the 587,000 USTs the EPA cites are now double-walled.” He explains that there doesn’t always have to be a leak or cleanup problem for a company to pursue retrofitting its tanks. “Tank owners can act proactively to comply with the secondary containment requirements,” he says. The benefit of retrofitting to achieve secondary containment, says Rieck, “is that it does not involve shutting down the gas station for four weeks and spending $150,000 to $200,000 to put in secondary containment.” For example, the average cost of the Delta Composite Systems GENESIS is only $30,000 for a typical 8,000-gal to 10,000-gal (30,283-liter to 37,854-liter) tank. This type of system is a viable solution where the existing infrastructure precludes tank removal and replacement.

Rob Pearlman, senior containment systems engineer at Delta Composite Systems, explains that “the people at Delta have been developing the processes involved since the early 1990s, but we have finally joined together all of the different components into a single retrofit system.” Pearlman adds, “Twenty years ago, systems like ours would have been only for special applications, for example, where an existing corroded or damaged tank could not be removed and replaced without disturbing a building. Now, it’s going to be a mainstream alternative to digging up and replacing tanks because it makes economic sense.”

Easy interstice installation

Instead of merely applying an interior lining, the Delta Composite Systems retrofit applies a composite sandwich structure, comprised of two faceskins separated by a hollow interstice, which allows any intrusive fluid to flow down into the centerline of the tank bottom, or sump, where it is detected and then removed by a pump or other means. The first step is to open the tank and pump out its contents. Rieck comments, “Sometimes you have to install a manway for access.” Next, the interior of the tank is abrasively blasted to get rid of chemical residues, rust and scale in preparation for bonding. Multiple layers of glass fiber mat are then hand laminated onto the tank, forming the exterior glass shell of the GENESIS retrofit barrier. After this, the ZPlex fabric is applied.

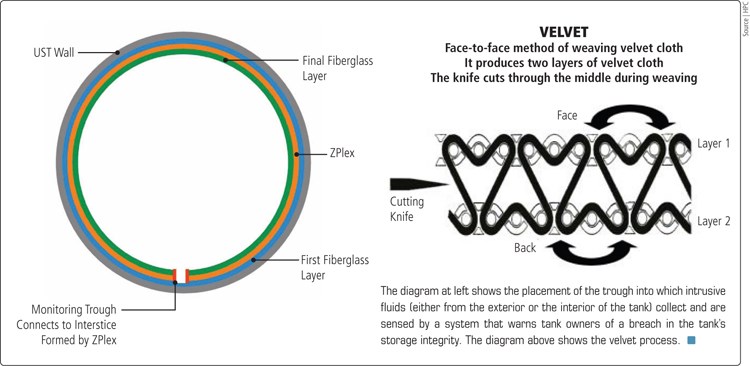

To manufacture ZPlex, 3TEX begins with a traditional process used to make velvet cloth. The method uses a special loom that weaves two thicknesses of fabric at the same time, but they are tied together with z-directional threads. A cutting knife then slits the two faces apart during weaving to create two separate fabrics. The cut z-fibers create the soft pile effect that gives velvet its plush feel (see illustration, at left). Glass is used to make the velvet in the production of ZPlex, but 3TEX does not cut the faces apart. This results in a fiberglass laminate with a built-in interstice. The difference for ZPlex is that foam is inserted into the space between the two fabrics during the weaving process. Notably, the foam is sacrificial, that is, it will be melted away after the tank barrier lamination process is complete and leave the interstice open.

Rieck describes ZPlex as “a woven roving on either side of a foam core material that goes away when heated, leaving a hollow cavity.”

The ZPlex process starts with spools of glass fiber and olefin foam that have been extruded into a continuous strand. These are fed into a single machine that produces the 3-D woven fabric, with foam strands woven into the gap between the two fiberglass faces during a one-step process. The foam strands maintain the uniform, set distance between the woven skins (important especially because installers must be able to stand and walk on the placed materials). The closed-cell foam keeps resin from invading the interstice during resin hand layup or resin infusion.

ZPlex is commonly woven with skins as thick as 0.5 inch/12.7 mm and with interstice columns (formed by resin-impregnated z-directional fiber between the fabric faces) as thick as 0.1 inch/2.54 mm in diameter.

After the ZPlex fabric is hand laminated along the tank surfaces, a trough is constructed along the centerline of the tank bottom using layers of bidirectional glass tape. This trough connects to the interstitial space formed by the ZPlex (see diagram, on left, above). A wet/dry cell is piped into the interstitial space. It detects any water or fuel that enters the space, which triggers an alarm and an inspection by the tank owner.

A final two to three layers of glass mat are applied over the ZPlex fabric to prevent potential leakage from porosity in the woven roving surface, followed by a gel coat, which forms the new interior surface of the tank. The fiberglass is allowed to cure ambiently, and then a proprietary system is used to heat the tank interior, causing the foam to melt. Because the foam is less than 5 percent solids, the melting foam shrinks to a tiny residue and opens up the interstice.

A variety of different resins can be used in the process to ensure compatibility with petroleum, acetone or other stored chemicals. Polyester, vinyl ester and epoxy are all options, but regardless of the choice, the resin that is used will have been tested to ensure sufficient chemical resistance. The composite tank retrofit system is flexible with respect to specifications and suppliers of glass fiber mat, and a range of materials have been used successfully.

After installation has been completed, a final quality check is performed by pressurizing the interstice with air and soap-testing the tank interior for bubbles while it is under pressure. If the interstice holds pressure for the prescribed test period, the retrofit process is certified by the installation technicians. For a typical 8,000-gal to 10,000-gal (30,283-liter to 37,854-liter) tank, the entire retrofit process can be completed by an experienced crew in three days. When asked about the potential loss of internal tank volume and the anticipated service life of the GENESIS system, Pearlman replied, “A 10,000 gallon tank will only lose a few hundred gallons of capacity, and the system is designed to provide a 30-year service life.”

Moving forward

GENESIS has already been tested at an approved testing facility and meets all EPA requirements for secondary containment retrofit of USTs. Now Delta Composite Systems will pursue certification to the Underwriters Laboratories (UL, Northbrook, Ill.) UL 1316 standard ("Glass-Fiber-Reinforced Plastic Underground Storage Tanks for Petroleum Products, Alcohols, and Alcohol-Gasoline Mixtures"). “This next step allows consideration of our system for use in situations where there are issues with the exterior shell wall of existing tanks, such that the retrofit may have to provide self-supportive structure,” says Pearlman. He sees GENESIS as a cost-effective and reliable containment solution with a bright future. “Underground tanks have seen many changes in regulations and containment challenges brought on by environmental concerns and evolving fuel product formulations,” he sums up. “GENESIS is a great example of how we can use the latest materials to provide new solutions for the industry.”

Related Content

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreWatch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More