Out of Autoclave

New filament to make composites "smart"

CW Conferences director Scott Stephenson premiers a showcase for new ideas overheard at CW Conferences.

Read MoreGKN A350 spar program update

Automated fiber placement to replace established tape laying/drape forming process for the composite rear spars on the new midsize commercial passenger jet.

Read MoreMaintaining fiber length in complex 3-D designs

Award-winning composite pallet showcases new LFT molding process from South Africa.

Read MoreLife Cycle Assessment: Are composites "green"?

Methods for calculating the impact composites have on the environment enable data-driven comparisons to traditional materials on a level playing field.

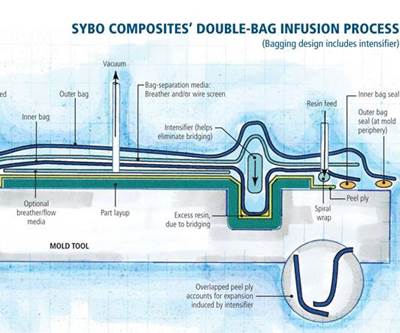

Read MoreDouble-bag infusion: Thickness gradient and pressure

Cliff Walker (Vacmobiles, Auckland, New Zealand), explains how the large pressure changes during infusion result in laminate compression and thickness variations across the part.

Read MoreAbsolute vacuum gauge

The following is an excerpt from Issue 12 of The Composites Letter, published by www.vacmobiles.com (reposted here by permission) that outlines the importance of using an absolute vacuum gauge to measure pressure levels during double-bad infusion:“Often called a precision vacuum gauge, an absolute gauge actually works the opposite way to a conventional dial type vacuum gauge.

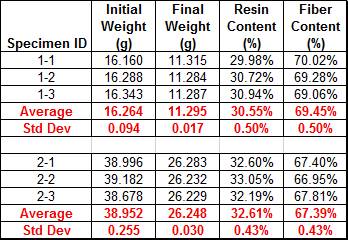

Read MoreDouble-bag infusion: 70% fiber volume?

A double vacuum-bag system and tight process control enable repeatable fiber volumes of 60 to 70 percent and improves consistency of infused laminates.

Read MoreIBEX 2010: Looking up in Louisville

A new location helps regenerate a recession-battered industry, drawing in more exhibitors and attendees than in 2009.

Read More