Out of Autoclave

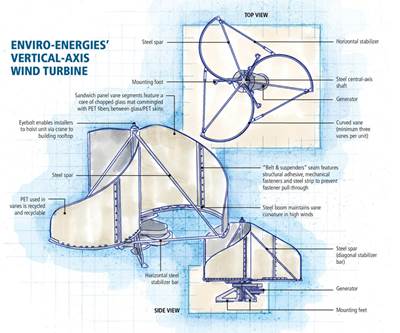

Small wind: Green energy gets greener

Kilowatt-rated vertical axis wind turbines supply green electric power where utility-scale turbines can’t.

Read MoreCOMPOSITES 2011 Product Showcase

Composite Technology magazine's review of the goings-on at COMPOSITES 2011, this year’s edition of the American Composites Manufacturers Assn.’s (ACMA, Arlington, Va.) annual trade show and conference (Feb. 2-4, Greater Ft. Lauderdale Convention Center, Fla.).

Read MoreCarbon fiber: Program news

In addition to the prognostications of carbon fiber industry watchers, attendees at Carbon Fiber 2010 (Dec. 7-9 in La Jolla, Calif.) also heard news of carbon fiber inroads to a number of composites programs.

Read More3-D woven reinforcements update

Suppliers make progress toward reinforcement preforms that exhibit comparable properties in the x, y and z axes.

Read MoreAntiballistics: Better defense, less expense

Armor applications grow on the strength of new markets, new composite materials.

Read MoreLow-volume thermoplastics: Differential pressure molding

Cost-effective tooling and presses enable semi-automated prototyping and low-volume production of thermoplastic composites.

Read MoreSingle bagging can do the job

Mechnical engineer Peter Schwarzel (CarbonWorks, Coombabah, Queensland, Australia) comments on the “Engineering Insights” article in the CT December 2010 issue, titled “Double-bag infusion: 70 percent fiber volume?”

Read MorePerformance requirements: CAI vs. OHC

John Russell, who manages nonautoclave research programs for the Air Force Research Laboratory (AFRL, Wright-Patterson AFB, Ohio), recently threw down the gauntlet at the Fall SAMPE conference in Salt Lake City, Utah: “Give us a 25 percent improvement in notch properties with no microcracking in high-modulus fibers.” While OOA prepreg suppliers can’t do much about fiber microcracking, Advanced Composites Group (ACG, Tulsa, Okla.) already has announced that its XMTM47 material will be commercial by next year, designed for 120°C/248°F service with the increased notched performance requested.

Read MoreOut-of-autoclave prepregs: Hype or revolution?

Oven-cured, vacuum-bagged prepregs show promise in production primary structures.

Read More