Out of Autoclave

CW opens up on out of autoclave, in February

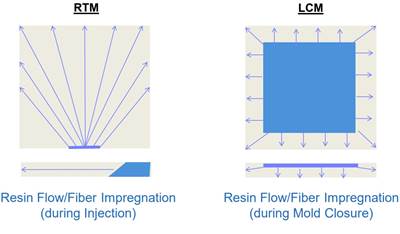

You may not know that CW has prepared a Supplement to the upcoming February 2016 issue that examines out of autoclave processing in detail. It asks the question: Can OOA options be matured sufficiently to yield parts with <1% void content, outside of the autoclave?

Read MoreIACMI starting to walk the talk

The Institute for Advanced Composites Manufacturing Innovation (IACMI) is six months into its five-year life and is showing signs of collaborative-based innovation.

Read MoreHow have composite bridges measured up?

The latest US highway bill includes a provision to assess performance of composite bridges built years ago, bridges that CW wrote about.

Read MoreWet compression molding

Automated process cuts cycle time and cost for CFRP parts with potential for 65% fiber volume via Dynamic Fluid Compression Molding variant.

Read MoreTurnkey manufacturing systems: Simplifying automated HP-RTM

Having offered turnkey systems for composites since the 1990s for sheet molding compound (SMC), long fiber thermoplastic (LFT) and glass mat thermoplastic (GMT), Dieffenbacher (Eppingen, Germany) now has automated systems for high-pressure resin transfer molding (HP-RTM).

Read MoreTurnkey manufacturing systems: Automated RTM for aerospace

German Aerospace Center’s (DLR) Center for Lightweight Production Technology site in Stade, Germany, has developed EVo, an automated production line capable of 100,000 complex composite parts/yr.

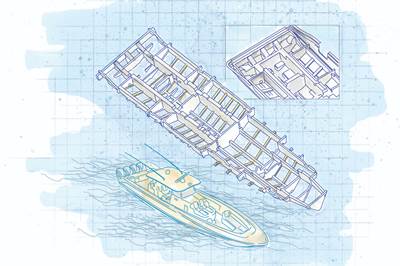

Read MoreWorld’s largest center console with single-skin hull

Navy RHIB concept goes commercial in the new HydraSports Custom Sueños high-performance offshore fishing boat.

Read MoreTurnkey manufacturing systems: Materials, markets and maturation

Automated production cells promise affordability and less risk in scaling up composites production, but are they really the path forward?

Read MoreCW Ideas in Action

Ideas are just ideas until someone does the hard work of putting them into action and seeing results. CW's editors, therefore, inaugurate an annual review of Ideas in Action, celebrating a handful of hot concepts that could make those who conceived them "household names."

Read MoreCarbon fiber elevator rope rides to the rescue high in the sky

Steel rope was once the material of choice for elevator function, but as buildings exceed 500m in height, it's just too heavy. Elevator manufacturer KONE is offering pultruded carbon fiber rope, called UltraRope, for elevators in the world's tallest buildings.

Read More