Out of Autoclave

Materials & Processes: Fiber formats for composites

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

Read MoreToho Tenax develops production system for carbon fiber composites

The process combines Toho Tenax' Part via Preform technology with high-pressure resin transfer molding (HP-RTM) to speed manufacture of carbon fiber composites.

Read MoreSAMPE Paris event highlights composites for auto, infrastructure

Summit Paris 2016, held one day before JEC World 2016, focused on emerging and creative technologies for cars and for bridges.

Read MoreCoriolis unveils automotive composites technologies and products

The parts, displayed at JEC World 2016, include the B-pillar for the Audi A8 and engine mounts developed in cooperation with Cooper Standard.

Read MoreTeijin sheds more light on Sereebo manufacturing process

Combining a chopped carbon fiber mat with nylon 6 resin, the process will be used to fabricate primary automotive structures in a forthcoming production vehicle.

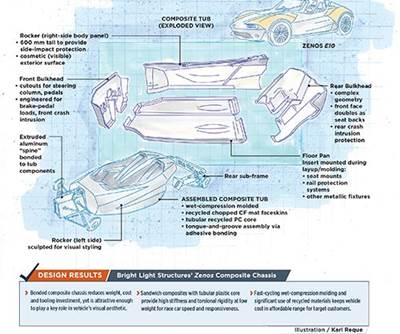

Read MoreForm + function = Classy chassis

Sandwich-composite chassis components double as structural and styling elements, reducing cost of ownership.

Read MoreLower cost, less waste: Inline prepreg production

New technologies move direct (fabricator-based) prepregging closer to reality.

Read More2016 JEC World in Paris (Day 2): Composites in transition

The JEC Europe show has evolved over the past two decades into a very large and very busy convention, with a grown-up feel.

Read MoreSolar Impulse 2: Pulse on the future

Not yet through their ‘round the world flight, this superlight solar plane’s airframe-proven materials are already destined for higher callings.

Read MoreNatural fiber composites: Market share, one part at a time

Suppliers and adventurous composites fabricators put the “feel good” aspect in the rearview mirror, winning customers by competing on price and performance.

Read More