Out of Autoclave

Thermoplastic honeycomb cores: Tough insulated sandwiches

Foam-filled nylon/polyester fabric yields sandwich panel cores with excellent mechanicals, durability, thermal insulation.

Read MoreLow-density SMC: Better living through chemistry

Proprietary sizing, special glass roving and microspheres strip 9 kilos of weight from Corvette body panels.

Read MoreGE Aviation, Batesville, MS, US

With a supply chain busy making commercial jet engines like the GE90, GEnx, LEAP and GE9X, GE Aviation has invested heavily in its composites capabilities in Batesville.

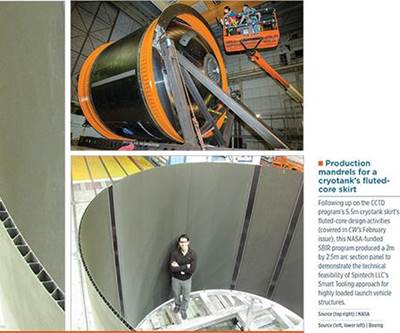

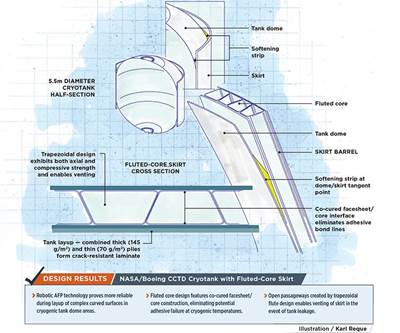

Read More“Smart tooling” cuts time and risk for complex unitized composite structures production

One-piece bladder tooling helps to actualize NASA/Boeing’s revolutionary fluted core design for next-gen cryogenic fuel tank skirt.

Read MoreFebruary supplement: Out-of-autoclave processing for aero use

We here at CW put together a supplement published with the February issue of the regular magazine that focuses on the technologies, tools and materials being used today in out-of-autoclave (OOA) processing for aerocomposites.

Read MorePlant tour: Spirit AeroSystems: Prestwick, Scotland, UK

Global aerostructures giant Spirit AeroSystems ventures into out-of-autoclave (OAA) composites manufacturing via vacuum infusion.

Read MoreFiber patch preforms help tailor kiteboard performance

Automated means for laying fiber only where needed offers new potential to fine-tune torsional stiffness and flexibility to board and rider styles.

Read MoreNASA/Boeing composite launch vehicle fuel tank scores firsts

Subscale 5.5m-diameter cryogenic tank demonstrator with innovative fluted-core skirt is formed via robotic AFP and cured out of the autoclave.

Read MorePolyurethanes: Collaboration and adaptation for optimal application

Guest columnist Kevin Meyer, associate scientist, Dow Polyurethanes, The Dow Chemical Co. (Midland, MI, US), asks, and suggests some answers to, the question, "Why have polyurethanes, given their performance advantages, not been adopted in place of other thermosetting resins in a host of applications?"

Read MoreDisruptive composite infrastructure

FiberCore Europe claims the "Holy Grail" of delamination-resistant FRP bridge and infrastructure components with its patented InfraCore technology.

Read More