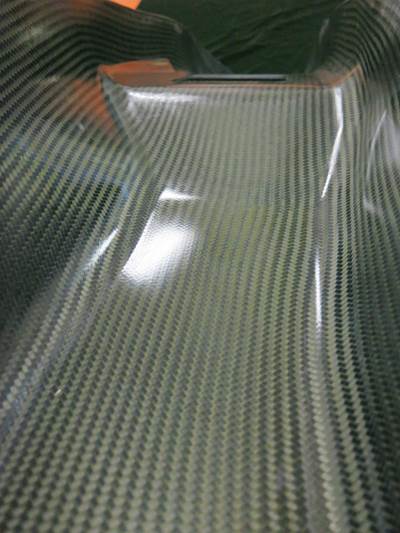

Prepregs

LAP Laser introduces new tablet PC and software integration capability

Airbus Stade and Czech supplier LA Composite report reduced layup labor and scrap while improving CFRP part quality.

Read MoreUltrasound evaluation of prepreg impregnation levels

The Ultran Group has developed non-contact ultrasound (NCU) that can accurately assess prepreg level of impregnation (LOI) with implications for out-of-autoclave processing, inline quality control and even automated tape laying.

Read MoreVX Aerospace: Small company, big performance

Innovative design, OOA manufacturing and C-PLY laminate construction produce “big fabricator” aerostructures in fewer steps at low cost.

Read MoreSAMPE Tech Seattle 2014 Preview

The Society for the Advancement of Material and Process Engineering’s annual fall Tech conference is now a spring event.

Read MoreRenegade Materials demonstrates OOA BMI in wing spar

Renegade Materials Corp. (Miamisburg, Ohio) has developed its RM-3004 out-of-autoclave (OOA) curable bismaleimide (BMI) prepreg for high-performance aerospace applications.

Read MoreLFI process: Molding strong and attractive spa enclosures

Dynasty Spas (Athens, Tenn.) finds a composite alternative to wood hot tub surrounds in a polyurethane (PU)-based long fiber injection (LFI) solution implemented by Romeo RIM Inc. (Romeo, Mich.).

Read MoreIn-house prepregging: Cost/benefit calculus

Scaled-down systems are flexible enough for R&D and production, but can they earn their keep?

Read MoreDeep draw: Unique laminate architecture enables bus part

For a major mass-transit manufacturer, Amtech LLC (Wapato, Wash.) successfully thermoforms a luggage cover with a remarkably deep draw of 40 inches (1,016 mm), using a laminate architecture that includes a top layer of 0.180-inch/4.5-mm gauge Grade 4800 thermoplastic sheet, supplied by Boltaron (Newcomerstown, Ohio).

Read MoreTenCate's acquisition of Amber Composites a sensible surprise

TenCate, known for years as a thermoplastics specialist, is signaling more and more that it wants to move into new markets with new materials.

Read MoreAutomotive SMC: The wheel comes full circle

James Canner (Sterling Engineering & Mfg., Royal Oak, Mich.) explains why it is, once again, an exciting time to be a part of the automotive composites industry.

Read More