Prepregs

Materials & Processes: Fiber formats for composites

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

Read MoreMaterials & Processes: Introduction

High strength at low weight remain the winning combination that propels composite materials into new arenas, but other properties are equally important. This article outlines the case for composites and introduces SourceBook's overview of the materials and processes used to make them.

Read MoreLower cost, less waste: Inline prepreg production

New technologies move direct (fabricator-based) prepregging closer to reality.

Read MoreJEC World 2016 exhibition and product previews

JEC World 2016 will be held in Paris March 8-10. These are some of the products that will be found at the show.

Read MoreCarbures: Conquering the world for composites

This global Tier 2 supplier produced 39,322 parts for Airbus in 2015, has sold seven RMCP machines to China capable of 40,000-75,000 composite auto parts/yr and is completing a study on opportunities for composites in oil and gas applications in Mexico. What next?

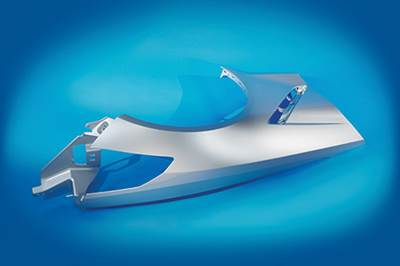

WatchVBO prepregs: The Vision SF50

OOA vacuum-bag-only process makes carbon fiber structures a reality for the world’s first personal jet.

Read MoreOOA overview: Market & opportunities

CW looks at where aero-OEMs and their suppliers are finding out-of-autoclave alternatives.

Read MoreFebruary supplement: Out-of-autoclave processing for aero use

We here at CW put together a supplement published with the February issue of the regular magazine that focuses on the technologies, tools and materials being used today in out-of-autoclave (OOA) processing for aerocomposites.

Read MoreCruise-capable rotorcraft exploits the performance of composites

The Carter Aviation Personal Air Vehicle combines the best of fixed-wing aircraft and helicopters, in an all-carbon composite design.

Read MoreVolvo 65: Identical and optimal composite spars and rigging

“One design” concept takes the boat out of the yacht-racing equation, pitting teams against the wind, sea … and each other.

Read More

.jpg;maxWidth=300;quality=90)