Prepregs

Formulation flexibility: Direct-SMC

Consortium applies inline-compounding technology to reinvent sheet molding compound.

Read MoreSpare wheel well: Functional integration

Gas-assist injection molding enables one-piece, one-shot thermoplastic composite/metal hybrid.

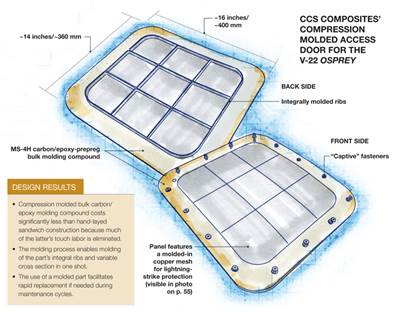

Read MoreSMC sandwich panels: Lean process opens doors

Patented process enables compression molding at lower pressures, saving capital equipment costs for panel fabrication.

Read MoreRedesigning for simplicity and economy

Military OEM makes the switch from sandwich construction to compression molding to optimize composite aerospace part.

Read MoreAirbus A350 Update: BRaF & FPP

EADS Innovation Works pursues qualification of Braided Frames for the A350-1000 fuselage and develops Fiber Patch Preforming for complex local reinforcements.

Read More2011 International Paris Air Show

At the 49th event, records are set for attendance and aircraft orders, and airframers go on record about composites-related developments.

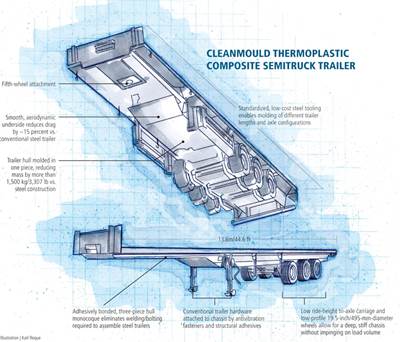

Read MoreThermoplastic composites: Sustainable transport

Cyclic PBT oligomers used to mold Class 8 semitrailer bed via vacuum-bag processing.

Read MoreTPCs on the Boeing 787 and Airbus A350

Although The Boeing Co.’s (Seattle, Wash.) 787 Dreamliner and the Airbus (Toulouse, France) A350 XWB have earned much press as showcases for thermoset composites in aircraft structure, both programs also have advanced the use of thermoplastic composites.

Read MoreUnder the hood: Thermoplastics tackle tough jobs

Reinforced plastics save weight and cost, increase underhood productivity.

Read MorePerformance requirements: CAI vs. OHC

John Russell, who manages nonautoclave research programs for the Air Force Research Laboratory (AFRL, Wright-Patterson AFB, Ohio), recently threw down the gauntlet at the Fall SAMPE conference in Salt Lake City, Utah: “Give us a 25 percent improvement in notch properties with no microcracking in high-modulus fibers.” While OOA prepreg suppliers can’t do much about fiber microcracking, Advanced Composites Group (ACG, Tulsa, Okla.) already has announced that its XMTM47 material will be commercial by next year, designed for 120°C/248°F service with the increased notched performance requested.

Read More