Prepregs

Automated Preforming, Part 2: Glide Forming

Flat layups are shaped into stringers with different cross-sections, lengths, thicknesses and curvatures using a single machine at rates up to 10 mm per second.

WatchPreforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

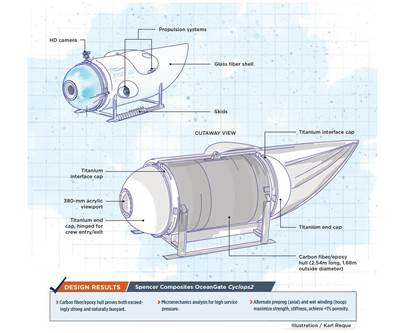

WatchComposite submersibles: Under pressure in deep, deep waters

Manned deepsea exploration calls for a highly engineered composites solution that saves weight and preserves life — at 6,500-psi service pressure.

Read MoreThe automotive industry’s “killer app”?

Automotive is king, and the killer automotive app will be the multi-material and all-carbon-fiber B-pillar.

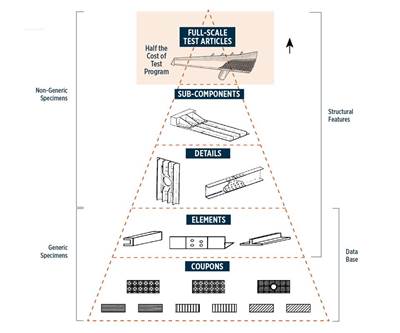

Read MoreAccelerating materials insertion: Where do virtual allowables fit?

In the quest to reduce the time and cost for aerocomposite design allowables development, will conventional physical testing and virtual testing go head-to-head or work side-by-side?

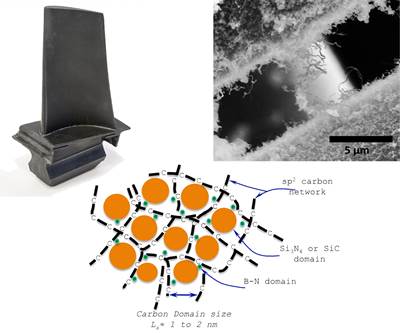

Read MoreCommercialization of CMCs and developments for next-gen performance

As industrial production of parts begins, new developments offer promise for higher-temperature and more damage-tolerant ceramic matrix composite (CMCs).

Read MoreHybrid carbon fiber/aluminum suspension knuckle

Yields 26% greater stiffness via bonded prepreg patch.

Read MoreJEC 2017 – Aiming for Industrialization

The exhibit floor in Paris reflected composites’ move toward high-rate and high-volume production.

WatchInFactory Solutions with Airbus

Airbus spin-off supplying Industry 4.0 systems for composites completes first qualification and discusses future developments for defect position visualization.

WatchCompression molding: New materials and markets

From multifunctional aircraft interiors to compounds using continuous fabrics to the growing use of recycled carbon fiber – compression molding offers new opportunities.

Read More