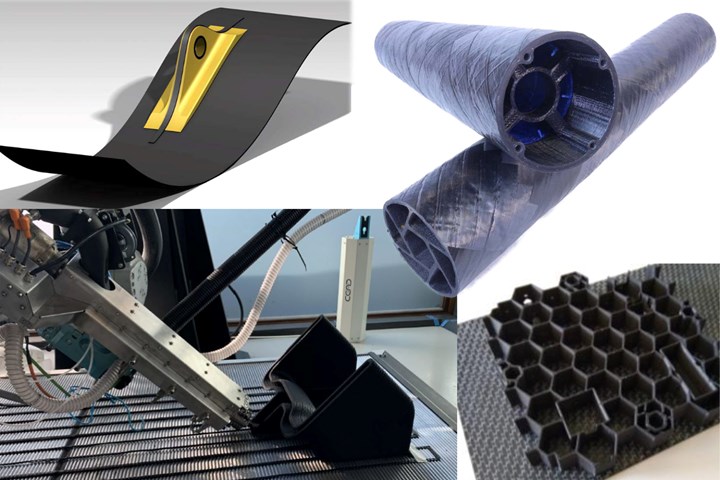

“Overprinting” onto premade CFRP surfaces and brackets (top left), hybridizing processes such as 3D printing and filament winding (top right), 3D printing cores onto AFP laminates and AFP skins onto 3D-printed cores (bottom right) and CEAD AM Flexbot 3D printing at 45 degrees (bottom left). Photo Credit: TU Munich, Chair of Carbon Composites

In September, I attended the virtual symposium "FUTURE COMPOSITE MANUFACTURING – AFP & AM", referring to automated fiber placement (AFP) and additive manufacturing (AM). This symposium was hosted by the Chair of Carbon Composites (LCC) at Technical University of Munich (TUM, Munich, Germany). The event also included TUM’s research partner Australian National University (ANU, Canberra). The symposium reviewed composites R&D capabilities at both TUM and ANU, as well as completed and ongoing projects with industrial partners including AFPT, Airbus, BMW, CEAD, DLR, Fraunhofer, GKN Aerospace, INOMETA, SGL Carbon and Victrex.

TUM collaboration with ANU began in 2010 with the AutoCRC project to develop compressed natural gas (CNG) storage tanks from thermoplastic composites. Joint R&D has continued since then, including formation of the Australian Research Council’s center for Automated Manufacture of Advanced Composites (AMAC) and three major focus areas at ANU:

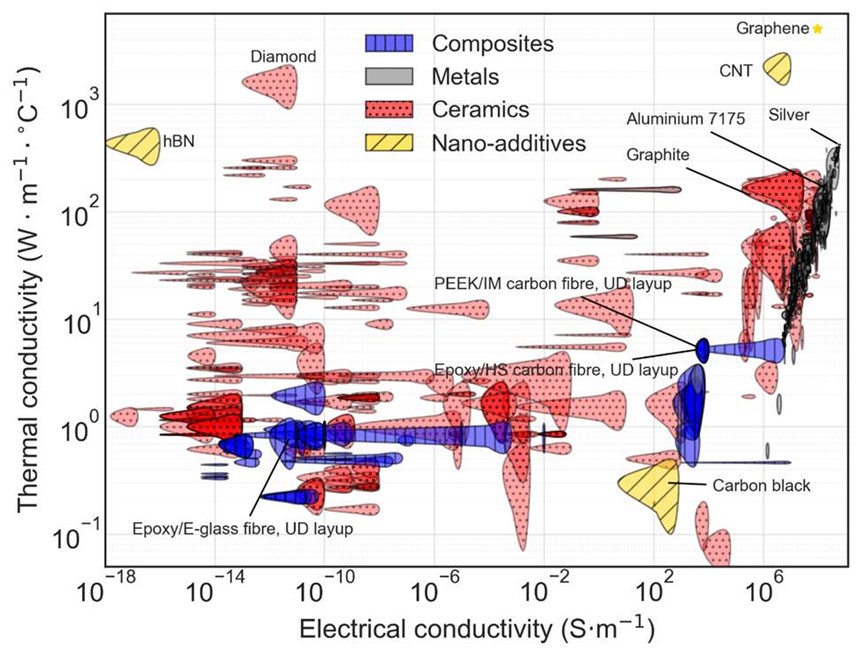

- Materials enhancement

- Nano-scale materials and coatings for enhancement of functional properties of carbon composites

- Graphene-enhanced prepreg tapes for thermal and electrical conductivity

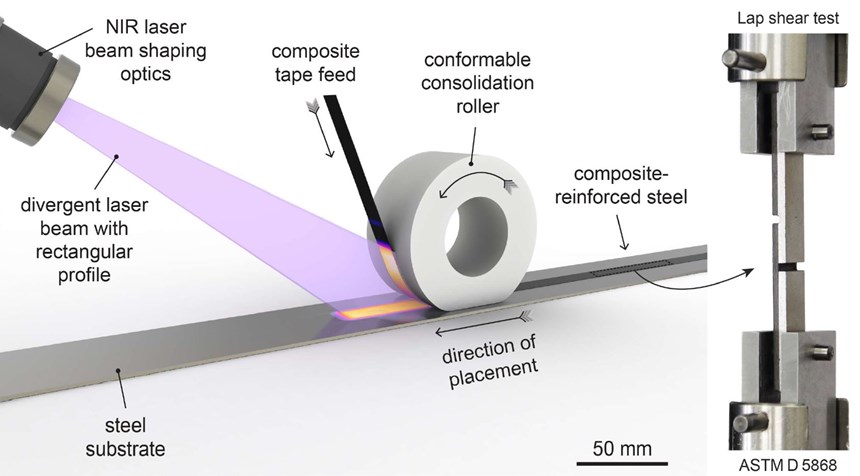

- Laser-AFP

- Project with Ford to develop composite-reinforced steel

- Digital control of heating bias, e.g. process stability for corners/3D geometries

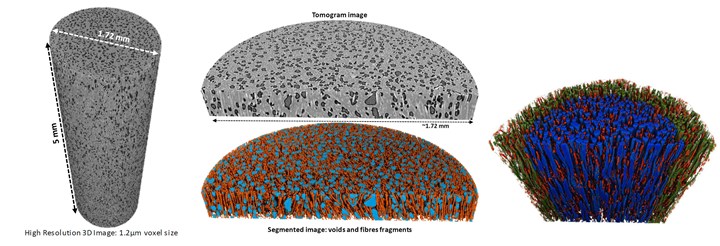

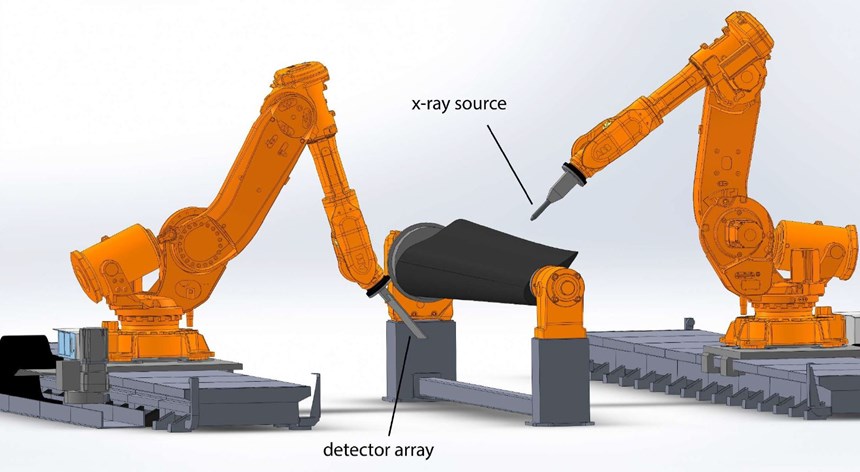

- Advanced diagnostics with x-ray CT

Victrex PEEK 450CA30 short carbon-reinforced 3D printing filament analyzed using computed tomography (CT) at ANU showing white fibers, gray resin and black voids (left and top center), red fiber fragments and blue voids (center) and red fiber fragments with outer filament voids in green and voids inside the filament as blue (right). Source | ANU, “Advanced Diagnostics of Carbon Composites Using X-Ray Computed Tomography (CT)” by Silvano Sommacal.

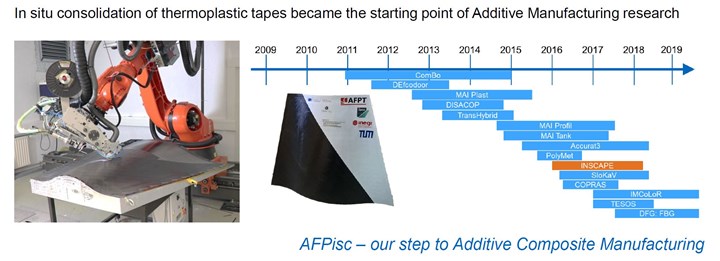

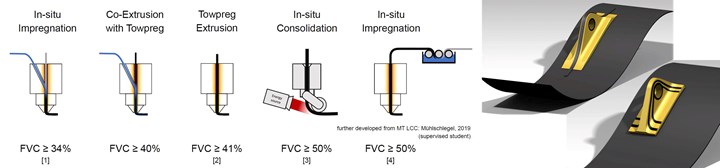

The keynote “New Horizons by Merging AFP and AM” was presented by Prof. Dr.-Ing. Klaus Drechsler, who established the LCC in 2009 with funding from SGL Carbon (Wiesbaden, Germany). Drechsler gave a background on the LCC and its composites research, including a long history working with in-situ consolidation (ISC) using automated fiber placement (AFP).

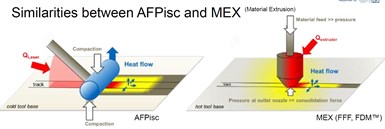

He discussed the similarities between material extrusion (MEX), the most common process used for 3D printing fiber-reinforced composites, and AFP ISC:

- Local, recurring heat treatment

- Layer based design & orthotropic material properties

- Material placement along 2D & 3D programmed paths and thermal activation between layers.

Drechsler then discussed the future needs for composites and how combining AFP and MEX could provide solutions, including near-term in tooling and longer-term in high-performance, lightweight structures that are both cost-efficient and ecologically sustainable.

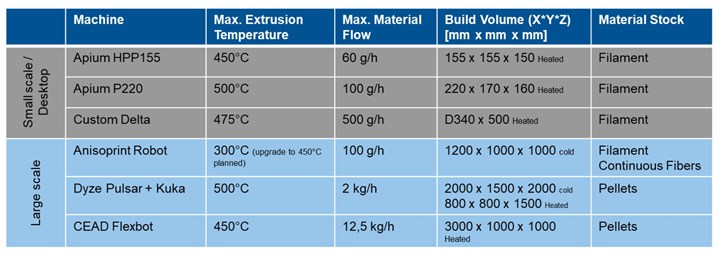

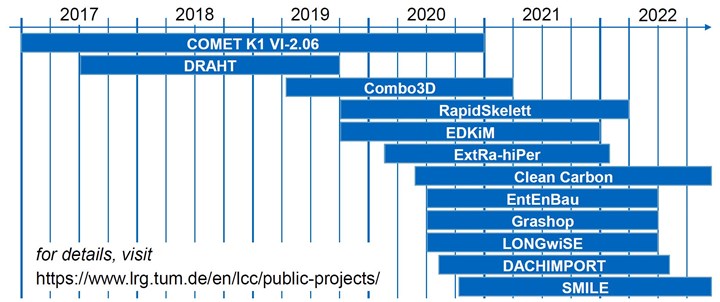

In outlining LCC’s capabilities, Drechsler gave an overview of its MEX equipment as well as past and ongoing R&D projects in additive manufacturing.

Additive manufacturing-related projects at TUM Chair of Carbon Composites (LCC).

Photo Credit: Klaus Drechsler, TUM Symposium Sep 2020

Regarding ISC AFP, recent and ongoing developments at LCC include:

- A vessel winding head to support industrialization of structures like pressure vessels, including hydrogen storage tanks

- Closed-loop control of laser beam heating

- Using a fluid-cooled roller for consolidation

- Characterization of tapes to optimize ISC.

LCC’s developments in MEX and 3D printing was further explored in multiple presentations over the next 2 days.

CEAD and large-scale 3D printing

The next presentation after Drechsler’s keynote was given by Maarten Logtenberg, executive director of CEAD (Delft, Netherlands). Founded in 2014, CEAD has sold commercial systems based on its Continuous Fiber Additive Manufacturing (CFAM) technology, both as a gantry-based enclosed cell (CFAM Prime) and a robot-based system (AM Flexbot). LCC owns the latter (see table above) and works with LCC on several projects (see CW articles on CEAD and its work with TUM LCC).

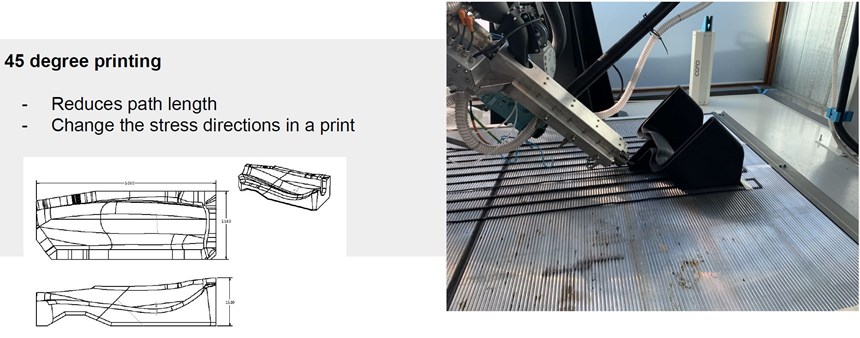

Highlights from Logtenberg’s presentation included CEAD’s development of hybrid solutions that integrate CNC milling, large heated print beds (1.2m x 3m and 1.2m x 2m) and heated rotary print beds. It is also pursuing even larger cells and 45-degree printing, as well as printing of fiber-reinforced tools for serial autoclave production of commercial aircraft parts.

Logtenberg noted that one of the main challenges for 3D printed autoclave tools is thermal expansion and tools much larger than 4 meters tend to expand too much (see “Hybrid, large-format additive tooling”), making it difficult to compensate sufficiently via tool design. The solution he put forward is to replace the chopped fiber reinforcement used mostly to date with continuous fiber deposited by systems such as AM Flexbot.

This path forward was seconded in the presentation, “Introduction of 3D-printed Track Intensifiers for Composite Flap Production” given by Thomas Herkner at GKN Aerospace in Munich, Germany. These 3D-printed CFRP intensifiers are used as tooling in the production of CFRP landing flaps for the Airbus A350 and A330. Although this successful program at GKN did use chopped fiber-reinforcement, Herkner showed a roadmap for further development which included using continuous fiber in 3D-printed tooling as well as, eventually, in the aircraft parts themselves.

This path forward was explained well by LCC research Patrick Consul in a recent CW blog:

“… this is a good way to generate experience with the technology. It is too early to try for structural parts that will fly. We will aim for this long-term, but printing tools will allow us to get the 3D printing process stable enough with high-performance properties and also develop the ability to accurately predict these parts and processes in simulation.”

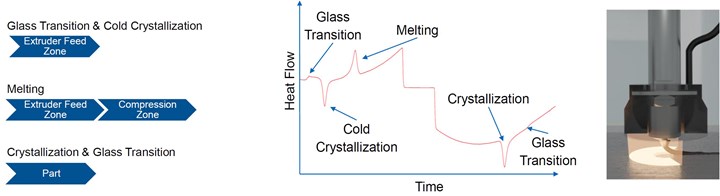

Consul also presented at the TUM symposium, looking at process design for large-scale, extrusion-based AM. He discussed how the glass and phase transitions shown below represent the largest change in material properties of chopped fiber-reinforced pellets that are melted and extruded in 3D printing systems like CFAM and AM Flexbot.

Glass and phase transitions during MEX of short fiber-reinforced thermoplastic pellets (left) and using a ring of controllable laser diodes to preheat the composite substrate during MEX-based 3D printing (right). Photo Credit: Patrick Consul, TUM Symposium Sep 2020

Consul’s work has analyzed how MEX parameters such as polymer viscosity and extrusion temperature and torque affect crystallinity in the printed composite, which in turn influences the ability to weld layers together during 3D printing. In addition to this layer-to-layer bonding, Consul has also explored fiber alignment and residual stress in the printed layers. One solution presented was using a laser to preheat the substrate during printing — widely used today in ISC AFP of thermoplastic composites — thus, transferring knowledge from AFP to AM. Initial experiments have used a ring of controllable laser diodes.

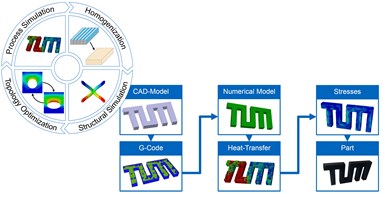

Virtual process chain for additive manufacturing of composites.Photo Credit: Matthias Feuchtgruber, TUM Symposium Sep 2020

Consul’s colleague, Matthias Feuchtgruber, presented later in the day, moving forward from process design and material characterization to developing a virtual process chain for composites AM.

Alexander Matschinski then presented on integration of endless fibers in composites AM, presenting the chart below, which became the basis for the amended chart I used in CW’s Next-Gen Supplement article on continuous fiber 3D printing. Matschinski also discussed work in design of continuous fiber AM structures and future development of “overprinting” onto premade CFRP parts and surfaces.

Concepts for direct fiber integration during continuous fiber 3D printing (left) and “overprinting” onto premade CFRP shells and curved brackets.Photo Credit: Alexander Matschinski, TUM Symposium Sep 2020

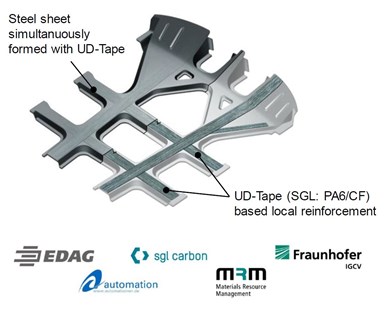

MAI CC4 HybCar project to develop a hybrid CFRP/metal approach for automotive underbody structures. Photo Credit: SGL Carbon, TUM Symposium Sep 2020

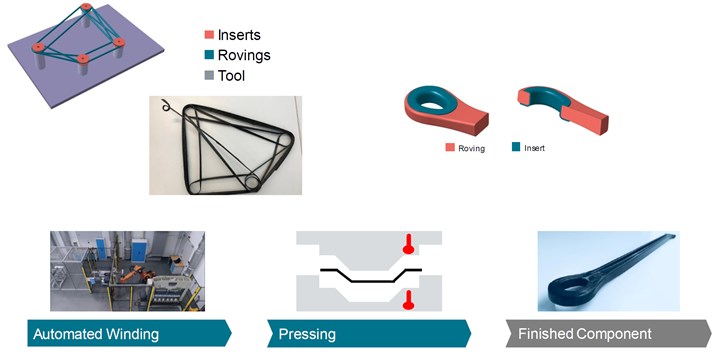

Other interesting applications of continuous fibers were shown by Dr.Christopher Ebel at SGL Carbon, including to reinforce steel underbody structures for automotive, reducing part count from 37 to 9 and cutting weight by 41%. Another concept was 3D winding using towpreg impregnated with snap-cure epoxy resin for load-optimized structures. This digitally-driven approach begins with simplification of complex loads and topology optimization, followed by automated manufacturing. Resulting parts can exploit form-locking of inserts into structures, enabling load introduction without stiffness loss. The latest 3D metal printing processes can be used for such inserts, further optimizing load-handling efficiency and cost reduction.

3D winding to produce load-optimized carbon fiber composite structures.Photo Credit: SGL Carbon, TUM Symposium Sep 2020

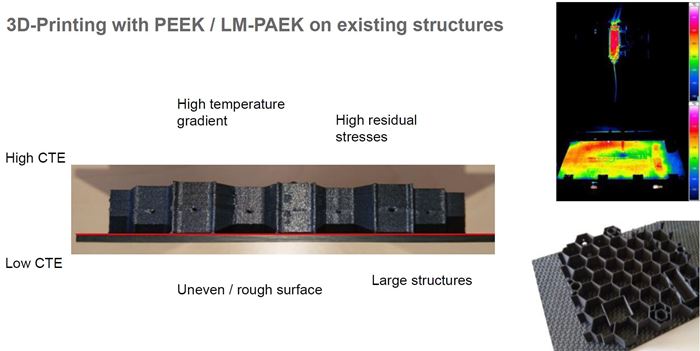

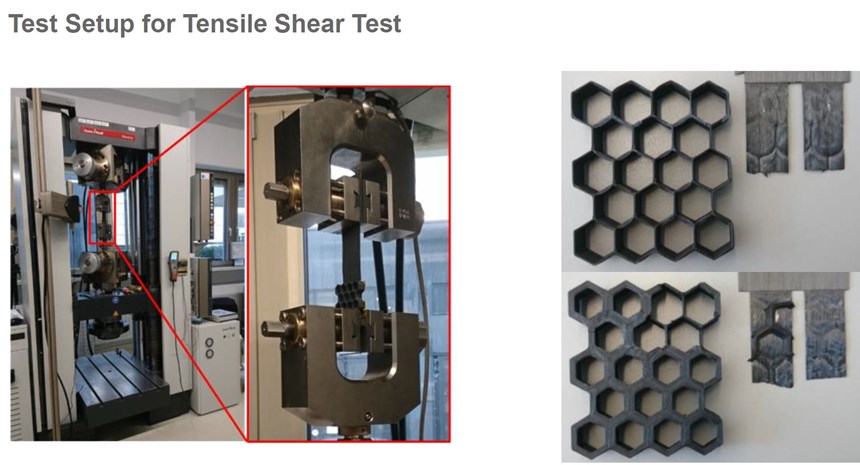

Sebastian Nowotny at DLR discussed combining 3D printing with ISC AFP of thermoplastic composites, including 3D-printing onto AFP laminates and AFP onto partially open 3D-printed structures. First experiments include 3D printing a core onto a premade CFRP skin and then AFP/tape laying on top of the 3D-printed core. Specimens were created and then subjected to tensile shear test to evaluate skin-to-core bonding.

Slideshow Title

Christian Weimer, head of materials for Airbus Central Research & Technology, discussed continuous fiber printing as part of the evolving technology landscape, aimed at reduced weight with reduced costs and increased sustainability that must be achieved for composites to secure a place on future aircraft. He emphasized that truly efficient 3D composites must employ:

- The right raw materials and intermediates – fibers, semi-finished

- Efficient processes and interfaces – AM thermoplastics, injection molding

- Adapted design and sizing – integral, fully 3D load-optimized)

- Surface and functionality – ESN (electronic serial number), SHM (structural health monitoring)

He also discussed the need for bio-derived fibers and resins in order to meet urgent climate and environmental sustainability goals.

The TUM symposium featured many more presentations, including summaries of work at ANU, and all were very interesting to show how composites are moving forward and how the LCC, working with partners worldwide, continues to envision what composites can achieve and push our industry forward.

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More