Processes

Schunk Carbon Technology to 3D-print tooling using Anisoprint technology

The carbon fiber and ceramic solutions developer has adopted Anisoprint’s Composer printer and materials to accelerate its custom tooling operations.

Read MoreGrid/skin structures explained

Composites expert and veteran Stephen Tsai and automated tape and fiber placement specialist MTorres have published “Composite Double-Double and Grid/Skin Structures: Low Weight/Low Cost Design and Manufacturing,” a design and manufacturing guide for the fabrication of grid-stiffened composite structures.

Read MoreGKN Aerospace breaks ground on UK Global Technology Centre

Twenty-five partners will also collaborate on the center, which will focus on research for additive manufacturing and advanced composites for aircraft.

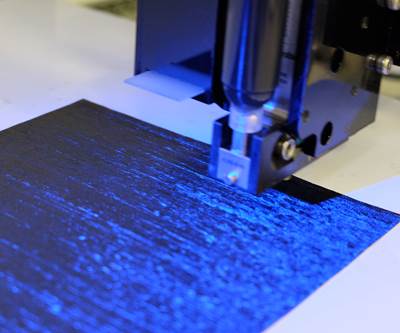

Read MoreEvolving AFP for the next generation

‘Aerospace quality at automotive pace’ is the mantra of the supply chain being developed for next-generation commercial aircraft. Automation is evolving to meet the challenge.

Read MoreCevotec’s Fiber Patch Placement wins Industry of the Future award

The additive fiber layup technology enables automated production of complex fiber composites.

Read MoreNanomaterials: Products, supply chain mature for next-gen composites

Development spans 3D and thermoplastic nanocomposites, nano-CMCs for hypersonics and nanomaterials safety and toxicity.

Read MoreNational Composites Centre purchases Coriolis C5 robotic gantry AFP

Developed for rate production of large, complex composite structures, C5 will be part of world’s most advanced, flexible dry-fiber deposition cell.

Read MoreSpirit AeroSystems debuts next-generation composite fuselage panel

The 18-by-12-foot (5.5-by-3.7-meter) demonstrator panel debuted at the Paris Air Show features integrated skin and stringers and offers substantial cost savings combined with strong performance attributes.

Read MoreSAERTEX provides material for 87.5-meter carbon fiber spar cap

The wind blade spar cap prototype, said to be the longest carbon fiber spar cap so far produced via vacuum infusion.

Read MoreCarbonPro box: new forming process

From materials to assembly, the carbon fiber composite CarbonPro box manufacturing process features innovative, automated preforming technologies.

Read More