Processes

Molecular Plasma Group obtains “Solar Impulse Efficient Solution” Label for MolecularGRIP

Solvent-free surface functionalization technology uses low amounts of chemistry and little energy to prime composites and dissimilar materials prior to bonding in addition to other functionalities.

Read MorePlant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

WatchCAMX 2022 exhibit preview: Addcomposites, IND Group

The co-exhibition shows customers a more complete visual of the value chains that can be implemented in the composites industry via Addcomposites’ AFP system solutions and IND Group’s cobot platforms.

Read MoreCAMX 2022 exhibit preview: Leesona

Leesona showcases high-quality, precision, automatic and manual winding solutions that are capable of working with a range of composite materials and fiber thicknesses.

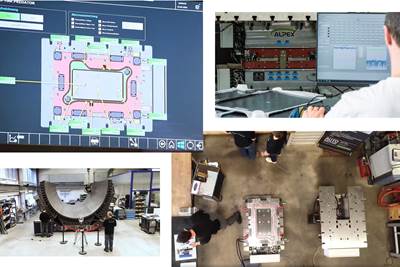

Read MoreDigitizing tools for composites production

Alpex Technologies focuses on industrialization, process and part intelligence and biocomposites in its next generation of tooling systems.

Read MoreCovestro sells additive manufacturing materials business to Stratasys

New ownership by Stratasys is expected to achieve faster growth, includes Covestro’s R&D facilities, offices and employees in Europe, U.S. and China in the agreement.

Read MoreCAMX 2022 exhibit preview: Schuler North America

Schuler’s smart control systems are said to achieve high material savings by reducing waste throughout the material cutting, distribution and forming processes.

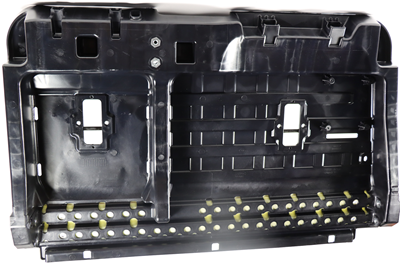

Read MoreToyota Tundra composite seatback design awarded 2022 Altair Enlighten Award

BASF, Flex-N-Gate, L&L Products and Toyota limited an all-steel assembly, cutting 60 parts down to four composite pieces for 20% weight savings.

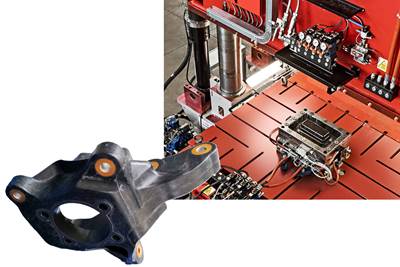

Read MoreA digital twin to validate SMC performance in suspension structures

High-fidelity, anisotropic behavior material card, integrated with process simulation, structural FEA and validated with CT and physical tests enables optimization proven in award-winning SMC suspension knuckle.

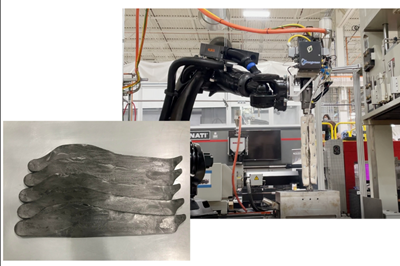

Read MoreLow-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

Watch