Processes

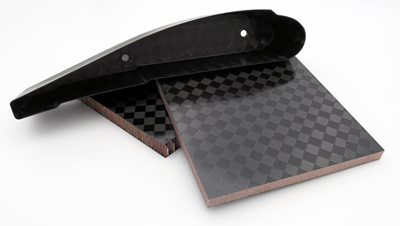

HexPly M901 prepreg accelerates product development cycles

Hexcel’s HexPly M901 prepreg system reportedly reduces production time of composite leaf springs.

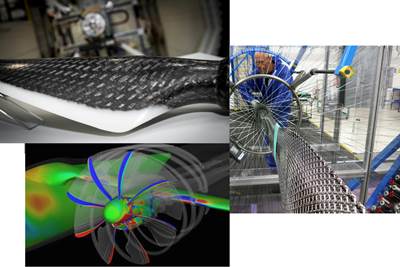

Read MoreDigiProp positions Dowty Propellers and its customers for sustainable, next-generation platforms

AMRC aids R&D program including foam thermoforming, complex braiding, thermoplastics and digital twin/thread for higher performance, lower weight with first applications in process.

Read MoreToray Composite Materials America launches flexible, adaptive 2700 prepreg system

Particularly geared toward emerging aerospace programs, the epoxy-based meets demands for high performance and process flexibility from prototype to high-volume production.

Read MoreSolution-based digital composites fabrication

MIT evolves liquid biomaterials into a new approach for sustainable engineered composite structures.

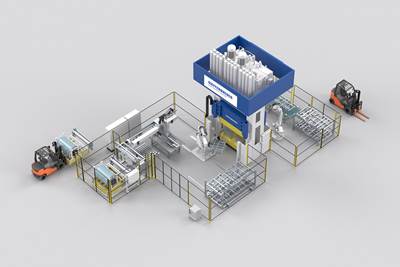

WatchDieffenbacher automates SMC lines for enhanced productivity and efficiency

Quick-change cutting system reduces changeover times to six to seven minutes, and ensures maximum reproducibility, even with the complex geometries.

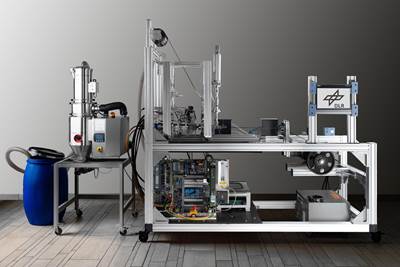

Read MoreReducing the cost of continuous fiber 3D printing materials

DLR has developed a novel approach to produce thermoplastic impregnated fibers for lower cost versus current slit-tape materials.

Read MoreAdditive manufacturing adds versatility to large marine structures

Dive Technologies and Moi Composites are among those extending composite 3D printing’s design flexibility past prototyping and into customizable end-use parts.

Read MoreBostik launches new offerings in high-performance specialty hot melt pellet, powder, web and film adhesives

With acquisition of Prochimir and Fixatti, Bostik aims to emphasize sustainability as one-stop solutions provider for global thermobonding market.

Read MoreCevotec fiber patch placement improves storage efficiency of composite tanks

Cevotec’s solution is to apply carbon fiber patches to the dome areas of Type IV pressure vessels, which reportedly yields 15% in material, weight and cost savings.

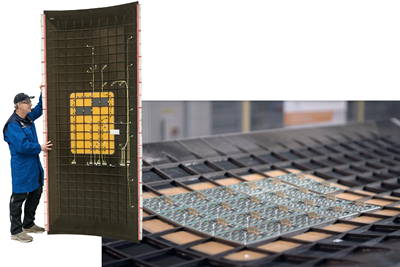

WatchIntegrating antennas into composite aerostructures

ACASIAS project integrates Ku-band array antenna in novel AFP orthogrid with drastically reduced tooling for more fuel-efficient, multifunctional CFRP aircraft fuselage panel.

Watch