Processes

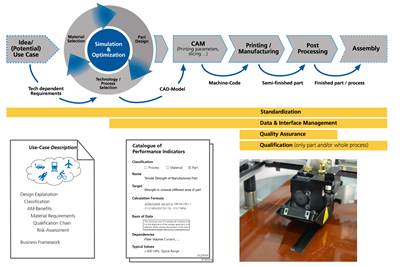

EmpowerAX strengthens accessibility to continuous fiber 3D printing

Platform joins technology users and providers to work on standards, tests and frameworks for faster, lower-cost evaluation and implementation of additive extrusion technologies for industrial parts.

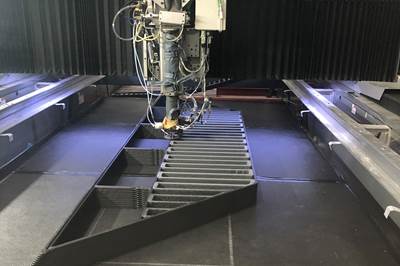

Read MoreCincinnati’s BAAM proves utility of recycled materials in AM

Cincinnati Inc. modified the extruder of its Big Area Additive Manufacturing (BAAM) system to be able to process virgin carbon fiber/ABS and recycled carbon fiber/ABS.

Read MoreSTUNNING project successfully develops 8.5-meter thermoplastic fuselage skin

Clean Sky 2 project under the MFFD program produces two segments of an 8.5-meter-long, 4-meter-diameter thermoplastic fuselage skin via NLR’s in-house AFP machine, with consolidation plans this summer.

WatchContinuous fiber-reinforced, 3D printed houses on the horizon

3D-printed modular building manufacturer Mighty Buildings moves toward certification of higher-strength, more sustainable glass fiber-reinforced housing panels.

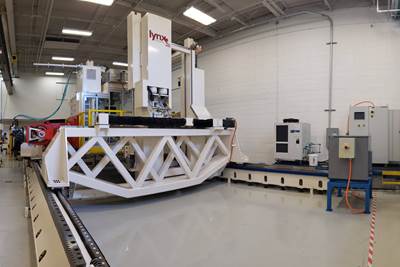

Read MoreQ&A: Importance of reliability in large-scale additive manufacturing

Thermwood Corp. CEO Ken Susnjara shares an LSAM supplier’s perspective on enabling reliable, continuous manufacturing performance.

Read MoreMarkforged next-generation fiber-reinforced 3D printer

Markforged will debut its newest continuous fiber-capable 3D printer, the FX20, at Formnext in November 2021.

Read MoreMcNAIR Aerospace Center installs Heraeus Noblelight humm3 technology

Composites heating technology will comprise of a fully integrated system with a plug-and-play head module to further extend AFP and cylinder production capabilities.

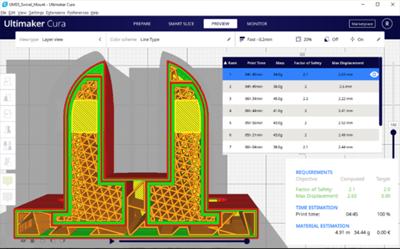

Read MoreTeton Simulation joins Stratasys GrabCAD Software Partner Program

Teton’s SmartSlice software for plastics and polymers will be integrated with GrabCAD DFAM Software Development Kit for improved print parameter validation and optimization.

Read MoreHenkel develops REACH-compliant structural adhesive for aircraft interiors

FST-certified Loctite EA 9365FST reinforces and bonds thermoplastic and thermoset substrates and can serve as a matrix resin on fiberglass to strengthen the thin walls of thermoplastic assemblies

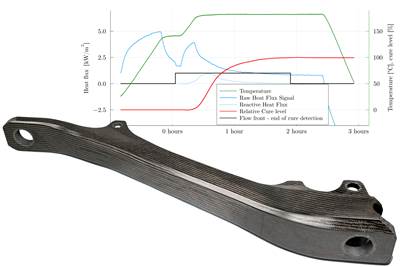

Read MoreSpeeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

Read More