Processes

Leuco PCD cutting tools enable high surface quality with long tool life

Leuco’s pure diamond milling, drilling and cutting tools achieve surface and durability requirements for CFRP automotive and aerospace components.

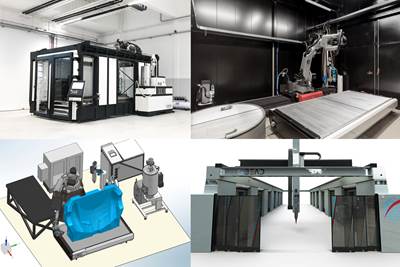

Read MoreAdapting composites 3D printing to evolving needs

Continuous fiber printing pioneer increases print cell options, size, hybridization and simulation capability for expanded applications.

WatchVirgin Orbit automates composites machining processes for LauncherOne rockets

Part of the company’s larger strategy for reducing cycle times and labor costs on its composite-intensive rockets, a customized machine center from Multiax America solves composite machining challenges.

Read MoreMighty Buildings raises $100 million to make carbon-neutral, 3D-printed construction a reality

Funding accelerates carbon neutrality roadmap which includes research and development of new composite materials produced from recycled or bio-based feedstock for net-zero construction by 2028.

Read MoreAirtech 3D-printed resins deliver composite tooling for competitive motorsport vehicles

BBi Autosport joins with Airtech Advanced Materials Group to develop high-performance carbon fiber body panels for its Porsche race cars using Dahltram resins and Print-Tech services.

Read More9T Labs assesses AM for medical, aerospace applications

9T Labs conducts two studies to assess the viability of its Red Series additive manufacturing system to manufacture a carbon fiber/PEKK aerospace hinge and a surgical tool.

Read MoreUT Austin installs Addcomposites AFP-XS with laser for in-situ consolidation of thermoplastic composites

Modular, compact and versatile AFP system to help University of Texas explore thermoplastic composites technologies.

Read MoreHexcel sponsorship showcases carbon fiber prepreg capabilities for UAV applications

Students from the University of Applied Sciences Upper Austria developed a camera drone from Hexcel carbon fiber prepreg and resin systems for a 42% reduction in structural mass.

Read MoreOrbital continues to progress toward commercialization

Orbital Composites is pursuing a variety of collaborative projects to apply its Orbital S robotic additive manufacturing system.

Read MoreUniversity of Bristol, NCC develop novel composite materials to assess performance in space

In-house developed matrices reinforced with carbon fiber will spend six months attached to the ISS to better understand and improve their functionality in extreme space conditions.

Read More

.jpg;maxWidth=300;quality=90)