Engineering Insights: Glass/Thermoplastic Hood Steps Toward Commercialization

The hood design for Hyundai’s QarmaQ concept car is evaluated against European and Japanese pedestrian safety requirements.

Before a new material for automotive hoods can be commercialized, it must pass numerous performance and safety tests, among them new requirements for pedestrian protection. Such is the situation with a thermoplastic sandwich composite jointly developed by SABIC Innovative Plastics (Pittsfield, Mass.) and Azdel Inc. (Lynchburg, Va.). Called IXIS, this lightweight, compression-moldable composite is stiff enough for structural applications and is the first to overcome creep/sag issues with thermoplastics that previously prevented their use in horizontal body-panel applications.

DEVELOPMENTAL FIRST STEPS

SABIC Innovative Plastics and a variety of development partners prototyped quarter-, half-, and full-scale parts to validate the material in a generic hood design and, using RocTool’s (Le Bourget du Lac, France) Cage System inductive-mold-heating technology, shortened compression molding cycle time to between two and four minutes (see “Learn More,” at right).

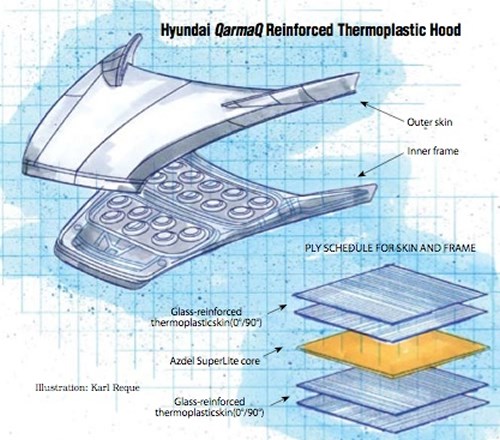

In the next step toward eventual commercialization, SABIC Innovative Plastics and Hyundai Motor Co. (Seoul, S. Korea) jointly produced a new hood design from the sandwich material for the automaker’s HED-4 QarmaQ (pronounced kar-mack). Project goals included an environmentally friendly technology; greater design and styling freedom; reduced weight, fuel consumption and CO2 emissions; and development of a pedestrian-friendly crossover utility vehicle (CUV) featuring an “Elastic Front” passive pedestrian-protection concept.

PASSIVE PEDESTRIAN-PROTECTION CONCEPT

Use of IXIS composites for the hood’s outer skin and inner frame was a key element in the vehicle’s Elastic Front passive energy-absorption concept, which combines energy-absorbing geometries with highly ductile materials to provide a lightweight solution for demanding pedestrian-protection test requirements. The CUV’s front end was engineered to meet European (EEVC WG17 Phase 2) and Euro-NCAP and Japanese (Japan-NCAP) pedestrian-safety requirements.

Design requirements include low front bumper beams that reduce lower-leg and knee trauma by preventing rotation of knees during first contact with the front end and preventing a pedestrian from “submarining” under the vehicle. Because this results in pedestrian contact with the hood, regulations require that the hood structure be ductile enough to deflect, thus absorbing impact energy to protect the pedestrian’s head and upper leg/hip. Potential solutions include passive systems that use thinner gauge steel or aluminum combined with greater deformation space (space between the inner hood and engine “hard points”); active systems, such as pop-up hinges that raise the rear of the hood to increase deformation space; and hood-covering airbags.

To determine if a design performs with an acceptable level of injury risk, acceleration measurements are made on full-size parts, and the physical-test results are used to calculate numerical Head Performance Criteria (HPC), which have been correlated to levels of injury risk. Various regulations specify test methods and acceptable HPC values.

To ensure that the QarmaQ hood would meet European and Japanese pedestrian-safety requirements, the design goal was to keep predicted HPC values below the standard: 1,000 for two-thirds of the hood’s surface area, and 2,000 for the remaining one-third. This involved a tradeoff between stiffness and deflection. The hood must be “soft” enough to absorb pedestrian impact energy without subjecting the test head-form to excessive acceleration. Yet it must be stiff enough to avoid sag/creep, minimize intrusion into the engine bay and meet all other OEM functional requirements. Excessive intrusion would re-quire increased packaging space between the hood’s inner surface and engine hard points, which might, in turn, necessitate a larger (and heavier) front end. A hood manufactured from IXIS offered the potential to provide comparable or better intrusion performance vs. thin-gauge steel or aluminium while avoiding cost and weight penalties incurred with active pop-up or airbag systems.

Following design freeze on the clay models and completion of the surfacing and panel split-up by Hyundai Europe Design, the general layout and dimensions of the hood’s outer skin were developed by SABIC staff.

Based on the final surface for the hood and the overall vehicle design, a number of head-impact locations were selected for modeling and subsequent testing, procedures which are defined in WG17 test requirements. Seven locations were selected for simulation from a larger number that would be explored during actual vehicle homologation tests. Because the hood is part of a system that includes hinges and bump-stops, which also absorb energy, these elements were included in testing, and hinges were modeled during initial CAE design work.

ABAQUS/Standard software (Dassault Systèmes, Providence, R.I.) was used for dynamic simulations of the various impacts under consideration, and HPC values were calculated with simulations results. Triangular, multilayer elements with sandwich-structure properties were used to build the model. Bonds between layers were modeled with material properties measured from cured-adhesive samples. Several iterations were conducted for different design concepts to explore the effect of varying energy-absorbing shapes for the inner frame on HPC. Because material properties were preliminary and not determined from dynamic testing, calculated HPC values and deflections were not expected to be accurate in the absolute sense. However, they were useful for ranking relative performance of designs under consideration.

PROTOTYPE HOOD FABRICATION

When the most promising design was identified via simulation, test prototypes were molded. IXIS blanks were hand fabricated at SABIC’s Polymer Process Development Center (PPDC) in Pittsfield, Mass. Two plies of continuous-glass-reinforced tapes with a polycarbonate/polybutylene terephthalate (PC/PBT) matrix were welded at 0°/90° orientation to the machine direction on each side of a PBT-impregnated, aerated SuperLite core sheet (both resin grades are experimental) and were overlapped at the edges to ensure complete coverage of glass reinforcement in the skin layers. The resulting 2,100-mm by 1,300-mm (83-inch by 51-inch) sandwich approximated what will be produced by the roller-lamination process planned for commercial production.

The IXIS sheets and CAD data for the proposed hood design (produced in Dassault Systèmes’ CATIA software) were transferred to tier supplier RangerPlast SpA (Via San Carlo, Italy). The CAD data were used to mill matched aluminum tools for the hood’s outer skin and inner frame. (Because cycle time was not a major issue for the prototype, an induction-heating system was not incorporated in this tooling.)

Sheets were preheated at temperatures ranging from 265°C to 285°C (509°F to 545°F) for between 240 and 300 seconds, then transferred manually to the press where the tool (preheated to 150°C/302°F) was closed and clamping pressure applied. Clamping pressures between 1,000 and 3,000 metric tonnes (2.20 million lb and 6.61 million lb) were evaluated in combination with holding times that ranged from 20 to 300 seconds. (Although parts formed at lower clamping pressures exhibited surface defects due to air bubbles trapped between the sheet layers during spot welding, this is not expected to be an issue with mass-produced sheet laminated between rollers.) Edges on formed parts were rough-cut with a jigsaw then clamped into a frame and fine trimmed with a CNC router to ensure repeatable dimensions and an acceptable edge finish.

Metal inserts were bonded into place on the top surface of the trimmed inner frame to reinforce attachment points for hinges, gas struts and latches. To activate the PC/PBT surface, Dow Automotive’s (Auburn Hills, Mich.) Betaprime 5404 primer was applied to bond sites. Metal inserts were attached with Dow’s Betamate 2810/1S adhesive, which allowed an open time of six minutes. When inserts were cured, the outer skin was bonded to the inner frame using the same primer and Dow’s Betamate 2810MV adhesive, selected because it allowed an open time of 8 to 10 minutes, providing more time to apply adhesive and position and clamp parts together. While they cured, parts were fixtured for ~20 minutes between a clamping frame and the cavity-half of the outer skin tool, which was heated with water to ~60°C/140°F.

Bonded parts were prepared for painting by hand removal of excess glue, followed by sanding of edges to remove sharp corners left from milling. Then a filler/primer coat was applied and allowed to dry. The completed assembly was hand painted in a spray booth, using a two-layer paint system. A matte gray topcoat was applied to minimize reflections in the high-speed video images that would record subsequent part testing.

TESTING SETUP AND PROCEDURES

RangerPlast shipped 24 completed hood assemblies to the pedestrian-protection testing laboratory, IAV GmbH (Gifhorn, Germany). A support frame was designed and constructed to simulate the attachment points on the QarmaQ body. Standard hinges and latches from Hyundai’s Tucson SUV were used for testing purposes. A laser distance-measuring device was mounted under the center of the hood to measure maximum deflection directly underneath each impact location.

A series of 24 impact tests were conducted to measure acceleration vs. time and maximum deflection at each impact location at required test conditions. For each test, impact speed, impact angle and impact location were set as specified by the test method.

HPC values bested the project target (<1,000), with most measuring between 300 and 800 (minimum 201, maximum 810) for “soft” areas of the hood, with deflections between 44 mm and 100 mm (1.7 inches and 3.9 inches). As expected, HPC values for “stiff” areas over the hard-mounted latch and near the bump-stop were quite high (2,600 and 2,100). In an actual vehicle design, such values could be reduced using deformable latches and bump-stop mounts. The test hoods showed very little obvious damage — local strain was within the material’s elastic limit. Because some level of damage (and, therefore, additional energy absorption) would have been desired, this indicated that the hood might be over designed.

Three tests were carried out with a hard point (a steel beam that spanned the width of the test frame) placed at differing distances below the center point of the hood’s inner surface. It was only when the hard-point was located 60 mm/2.4 inches from the undersurface of the hood that the HPC value exceeded the limit of 1,000, indicating that a deformation distance of ~70 mm/2.8 inches might produce acceptable HPC values.

Development continues. Because IXIS is a new material, further characterization work is ongoing at in-dependent laboratories to develop a property profile for each layer in the sandwich over a range of temperatures and strain rates. Meanwhile, Hyundai will complete homologation requirements (full mechanical, dimensional and crash testing), which might be followed by crash testing of full-size hoods on real vehicles. Hyundai also is pursuing a Class A paint-ready finish out of the tool. Finally, Hyundai and SABIC are investigating ways to minimize cycle time and energy requirements, including tool edges designed to minimize edge-trimming requirements and “net-shape” molding, using pretrimmed sheets to minimize or eliminate edge trimming.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRead Next

Inside Manufacturing: A Reinforced Thermoplastic Car Hood?

Low-density GMT-cored sandwich construction and novel inductive mold-heating strategy are a viable option for horizontal body panels.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)