GKN leads “STeM” program to successful conclusion

Technical achievements are credited to successful partner collaboration.

In Europe and North America, many composites developments are undertaken by groups of companies working in collaboration. These efforts are encouraged by funding at either the level of the local state, or at higher levels, such as the European Union or, in the US, national government agencies. The obvious aim of these programs is to raise the Technology Readiness Level (TRL) of new manufacturing processes, but an equally important effect is to encourage competitors to collaborate locally, increasing the quality of work and forming a basis for possible business developments that stimulate economic health.

One such program, the Structures Technology Maturity (STeM) project, began in the UK in April 2012 and was completed in 2014. The partners were GE Aviation (Hamble, England), Bombardier Aerospace (Belfast, Northern Ireland), Spirit AeroSystems (Prestwick, Scotland) and the program leader, GKN Aerospace (Isle of Wight, England). Funding came from the UK government, via its Technology Strategy Board (TSB), now known as Innovate UK, and, therefore, was available to all companies with business locations in the UK, a fact that benefited the three of the four partners that are owned by North American corporations.

Axillium Research (Daventry, UK), which acted as the Project Management Support Office, both for the program and its partners, ran an initial workshop, which determined how teams were formed for each theme. As a result, the partners worked (or didn’t) on various topics, depending on their interests. For example, Bombardier and GKN Aerospace worked on hollow structures, but all the partners were involved with modeling of springback phenomena.

The program manager was Craig Carr, from GKN Aerospace, and the TSB monitor was Ray Browne. The TSB described the program as Exemplar, an example that others should strive to follow in respect to what it achieved and how it was run. Carr believed the project received this rating not only for its technical achievements but also for the excellent collaboration between the partners.

The program looked at a number of different structures, among them a winglet and a main wingbox rib (see Fig. 1). The Advanced Winglet Program, carried out at the GKN Aerospace facility on the Isle of Wight, aimed to replace the traditional design of metal ribs and CFRP spars clad in CFRP skins, with a one-piece, co-cured upper skin and waffle stiffener (see Fig. 2). To this, the lower skin would be mechanically fastened by a highly automated assembly process (see Fig. 3). Other than the tip and the leading edge, the structure was entirely composite.

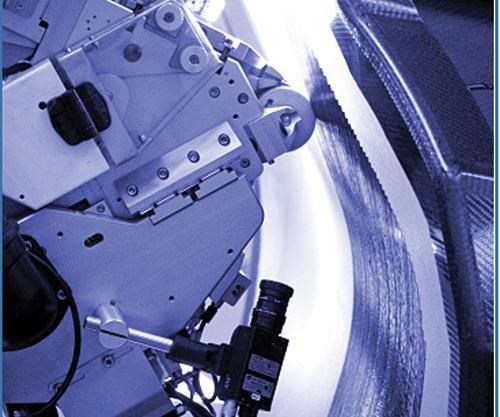

The lower skin was manufactured using robots equipped with automated fiber placement (AFP) heads (see Fig. 4) from Coriolis Composites (Queven, France). These were used to produce a complex, highly optimized layup only constrained by the need to fit the compact Coriolis head into the tight radius of the component. The manufacturing times were reduced by 70% compared to those of a conventional structure. For this initial program, the upper skin could not be optimized, because it was layed up manually, but in a follow-on program, both skins will be made with an AFP system to match a fully optimized design.

In-process inspection was used to monitor the quality of parts made during this project. It used an infrared camera to monitor the small temperature differences as the skin cools from the heat input of the AFP machine, as in a thermographic nondestructive testing (NDT) machine. The process called attention to any bridging or gaps between tapes. Two options for mounting the camera were tried. One had the camera mounted on the laying head and the other mounted it at a fixed point near the component. The latter, a more distant vantage point, made the camera less effective at finding small defects. When it was head-mounted, the camera yielded better image resolution of the defect, but had the disadvantage of increasing the size of the head (see Fig. 5), thus restricting the tightness of corners into which it could lay material. A “clash avoidance” simulation was developed to analyze the potential for head/tool collisions in such scenarios.

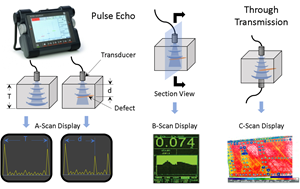

After the components were cured, ultrasonic C-scan NDT was used to detect voids. One innovative development demonstrated here was the use of a flexible transducer head. This had to be used because of the tight curvature of the component.

Another aspect of the program was to develop modeling techniques for the deformation of composites into complex shapes. Tim Dodwell from Bath University (Bath, UK) based his effort here on some work done in the early 1900s by two French brothers, Eugène and François Cosserat. This team, a mathematician and an engineer, applied modeling techniques to tectonic plates in the Earth’s crust. Today, the same methods have been applied to composite laminates to capture the formation of defects in large parts and wrinkling in the radii of 2D corners. This technique’s development has enabled computational tasks to be undertaken for a fraction of the cost of conventional techniques.

Although the use of composites has provided avenues for improvements in component design and manufacture, particularly reductions in parts count, because they enable the combination of multiple parts via one-shot manufacture, there remains a need to address the high costs of assembly. These include the ongoing cost of labor and the non-recurring cost of the fixtures to hold composite and metal parts that must be joined in the correct positions relative to one another.

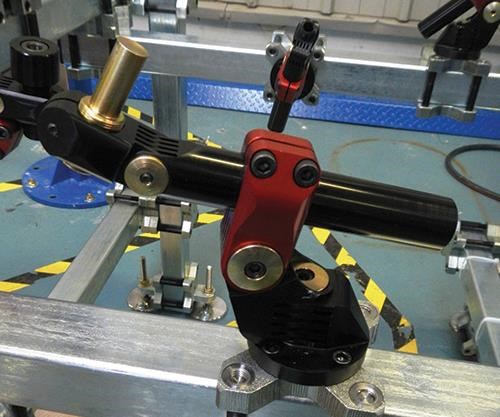

Fixtures have been developed that replace very large and heavy steel structures with much lighter tooling. These fixtures feature reconfigurable datum — that is, the fixture, by design, is able to cope with variations in the component parts, such as thickness or shape distortion. Metrology is used to assist critical positioning (see Fig. 6). Notably, the cost of such tooling is less than half that of conventional fixtures. One recent comparison quoted was £200,000 (US$308,490) for conventional manually adjusted fixtures compared with only £50,000 (US$77,122.50) for new, lightweight tooling fixtures that, at the point they contact the part, can automatically adjust to part variations.

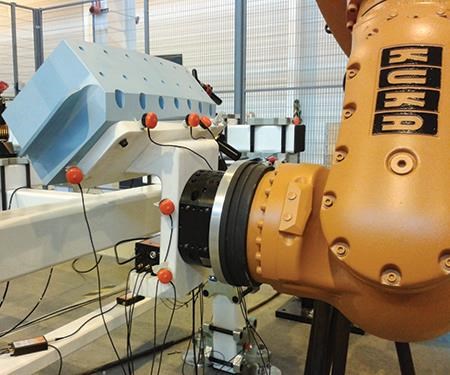

Robotic assembly was used with support from the AMRC (Rotherham, UK), based on earlier work done by Bombardier (Belfast, UK) with robotic drilling. It is anticipated that exploi tation of the automation and advanced assembly methods may be used on future programs for civil and business jet major structures from parts made in the UK at GKN’s composites facilities on the Isle of Wight and at the Filton Manufacturing Centre.

The benefits that the program demonstrated included:

- Overall cost savings of 17%, with weight neutrality. In the next phase, AFP will be used for the waffle and upper skin. This will save more weight, due to optimization of the layup that can be achieved by the use of AFP.

- The demonstration of achievable deposition rates 2x-4x faster than manual deposition, depending on the structure, compared with manual layup rates, will be used to develop the business case for future work.

- Projected investment savings of 50% by the application of automated drilling and filling.

- In-process inspection was successfully applied to an AFP head, and it was able to detect sub-surface defects.

- Advances in modeling deformations in composite plies in a number of common prepreg materials, such as Hexcel 8552, M21E and M91, using Cosserat modeling techniques.

Finally, this report on the project would be incomplete without noting the remarkable way the STeM partners, who are competitors in the aerostructures business, were able to work together, and that this not only worked to their mutual benefit but also was rewarded by funding to the same team for another project, VIEWS (Validation and Integration of manufacturing Enablers for future Wing Structures), started in April 2015.

Related Content

NDT inspection services, automated systems serve aerospace needs

CAMX 2023: Arcadia Aerospace Industries demonstrates its commitment to navigating the rapidly changing aerospace manufacturing landscape with robotic-based machines and motion control systems, certified facilities for NDT services and conducted training and recruitment.

Read MoreInnovation in ultrasonic inspection and nondestructive testing

With increasingly complex structural components working their way into aerospace programs, the need for versatility in inspection and testing capabilities is growing.

Read MoreNondestructive inspection methods available to composites manufacturers

An overview of composite laminate inspection techniques ranging from manual testing methods to more advanced, noncontact options.

Read MoreLoop Technology develops robotic arm for wing box inspection

Part of an R&D project with Spirit AeroSystems, the seven-axis Bravura robotic arm automates inspection and sealing within small spaces like aircraft wing boxes.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More