Robert Stapleton of Industrial Fiberglass Specialties sprays gel coat onto an FRP console built for use by the U.S. Air Force. Source | CW

Industrial Fiberglass Specialties (IFS, Dayton, Ohio, U.S.) is an old-school fiber-reinforced plastic (FRP) pipe factory. The company has been manufacturing FRP products for more than 40 years and has expertise in a wide range of industrial applications and products.

The shop has been in operation since 1979 and is situated in a building that was once the Bluebird Pie Bakery. Today, the company’s primary business is custom fabricator of products for OEMs and other fabricators that require high technology, specialized resins, and expert tooling and machining capabilities.

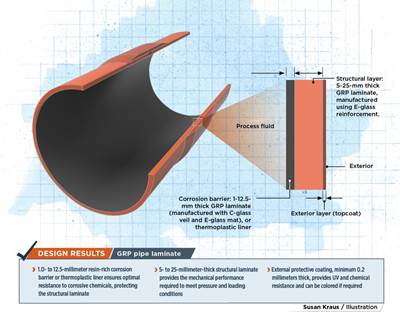

IFS manufactures composite pipe and fittings for corrosive industrial service including its Series 5700 piping, a filament-wound, fiberglass/methacrylate-modified epoxy composite pipe. The product is designed to handle highly corrosive and abrasive environments. Applications for the piping include chemical process piping, acid drains, wastewater and sewage systems, process plant piping, power plant and fly ash piping, water treatment piping, hazardous waste piping and industrial service for severely corrosive liquids.

Source | CW

IFS’s mainstay is industrial pipe and pipe fittings, but the company also makes specialty items including such custom industrial products as tanks, apparatus, plating tanks, bath tanks and storage tanks.

The company recently worked on a console for a flight simulator for Alion Science & Technology (Alion, Washington, D.C., U.S.), which developed a monitor for Wright Patterson Air Force Base (Dayton, Ohio). IFS received an order for a total of 22 to 24 consoles for this simulator console over the past year. The console presented a few unique challenges, including intricate cutouts for switches. Previous attempts to create a console for the simulator had proven unable to meet the complex shapes and necessary dimensions.

“[Alion] brought us the console, we looked at it, started building it and then realized that some of the stuff they wanted done for the drill holes and the cutouts was taking a lot of extra time to lay out by hand,” says Robert Stapleton, IFS production supervisor. “So what we did is we made a new mold that gives us everything we needed. [The holes and cutouts are] scribed and drilled on in advance, so when you pull the part out, it’s a much quicker process.”

Source | CW

IFS made a new, two-piece fiberglass mold and produces the part via hand layup. Once the two pieces are trimmed and bonded together, the cutouts and inserts for screws are machined into the part.

Stapleton explains, “We spray down the gel coat, and then we do three layers of material for the hand layup process. Then we pop it apart – there is a top and a bottom mold – and do all the necessary trimming. We then bond the two pieces together and then do all of the cutouts and the inserts for the screws. ... Once we get that done, then we do all of our body work to it. And then I take it over and I paint it.”

Wright Patterson wanted a very specific paint job for the part. The mounting bracket for the console is made of powder-coated aluminum, and the console itself needed to match the matte look of the support mechanism.

“[The customer] wanted Army-type rugged matte black, but powder coat doesn’t normally stick to composite,” says Stapleton. “It took me a couple tries, but I was able to paint it to make it look like it was powder.”

IFS’s approach to fabricating the complicated console shortened the production time from several weeks to under a day. The company is now making two of the products every two weeks for the Air Force.

Related Content

ATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

Read MoreFyous launches infinitely reusable manufacturing mold tech

PolyMorphic Moulding technology uses 28,000 digitally controlled pins to create a shape from a 3D CAD shape in less than 20 minutes, achieving zero waste and enabling parts production 14 times faster than 3D printing.

Read MoreAddyx carbon exoskeleton technology enables molded ribs inside hollow composite structures

Using a water-soluble mandrel, carbon exoskeleton opens paradigm for topology-optimized composites, cutting weight, manufacturing time and scrap rate.

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Read MoreRead Next

Corrosion-resistant composite piping over the long haul

Three decades of lessons learned using corrosion-resistant glass fiber-reinforced composites in piping at SABIC’s Netherlands chlorine production plant.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More