JEC World 2018: Highlights

You will read more about what we discovered at JEC World 2018 in the coming weeks and months, but for now this is a quick review of some of the highlights from the world’s largest composites trade show.

Following is a summary of some of the highlights CW discovered at JEC World 2018 in Paris (March 6-8).

ELG Carbon Fibre (Coseley, West Midlands, UK), known for recycled carbon fiber materials, used the show to announce plans to increase its Coseley facility capacity to satisfy increasing demand from commercial applications that require significant product supply. The company says the investments will increase the capacity to recover carbon fiber from uncured prepreg and laminate feedstock and to further commercialize the company’s CARBISO product line for reinforced thermoplastic compounds. ELG was in the spotlight as a winner, in the Railway category, of a JEC Innovation award for its participation in a research project to produce a novel rail “bogie” or frame (to which the axles and wheels are attached, to support a locomotive or rail cars) made with recycled carbon materials. Project partners include Alstom Transport (Saint-Ouen, France, and London, UK) Magma Structures (Portsmouth, Hampshire, UK), the University of Birmingham and the University of Huddersfield, both in the UK. Says managing director Frazer Barnes, “This innovative rail bogie project, with significant funding coming from the UK’s Rail Safety and Standards Board, is showing that the composite part is 75% lighter than a standard steel structure, so there’s less track weight, which saves considerably on track and wheel wear. Testing will continue into 2019.” On display at ELG’s stand were several automotive parts made with ELG’s Carbiso recycled carbon fiber mat, including a hood (bonnet) produced by Gurit Composite Composites Ltd. (Newport, Isle of Wight, UK) that can withstand all crash loads. Barnes says that the needled recycled fiber mat can withstand E-coat processes and produces surprisingly good Class A finish.

GKN Aerospace’s (Redditch, Worcestershire, UK) Fokker business (Papendrecht, Netherlands) group revealed that it continues to move forward with innovative thermoplastic composite aircraft parts. The company has been a supplier to Gulfstream Aerospace Corp. (Savannah, GA, US) for more than 20 years, in all of GAC’s large and ultra-large programs. It makes a common thermoplastic rudder part for the G500, G600, G650 and G650ER and produces the entire empennage structure for the G550, G650 and G650ER. According to the company’s Arnt Offringa, the build rate is increasing thanks to the part commonality, as well as new technology for inductively welding rudder parts, and “we are improving the industrialization and manufacturing engineering for making these parts.”

An interesting collaboration was announced at the show between CG TEC (Spalt, Germany) and Refitech (Waalwijk, Netherlands), two providers with a long history of producing client-specific industrial composite solutions in a wide range of application areas, using a wide range of composite materials and processes. The purpose of the new partnership is to cooperate in providing the composites industry, and in particular, small start-ups or entrepreneurs, with off-the-shelf, standard, carbon fiber products — round and square tubes, rods, plates, cables, connectors, braids and more. “Customers need help in getting into series production. We’re filling a niche for small customers who can’t afford tools but who want to work with carbon composites,” say CG TEC’s general manager Oliver Kipf and Refitech’s technical sales engineer Bas Nijpels.

One of the special events organized by the JEC was the “Startup Booster” competition, in which 10 entrepreneurial startups pitched their company ideas to a heavy-hitting jury made up of the head of Airbus’ composites manufacturing technologies, Daimler AG’s manager of hybrid material concepts, and many more. One of the highlights of the competition was an interview with Clementine Gallet, founder and CEO of Coriolis Composites (Queven, France) called “Ask me anything,” where Gallet took questions from the startups and others in the audience. Here’s a sampling of her insights into starting a composites business:

- Question: What are the three most important points to take care of when setting up a business?

CG: “1. Protect your idea with intellectual property tools; 2. Build up a network, at industry shows and conferences, and develop your idea with professionals and companies within your industry; 3. Focus on one (or two) idea(s) only, otherwise you will lose focus.” - Question: What impresses you about these startups?

CG: “First of all, it is interesting to see the personalities. I see human beings with the motivation and passion of doing the best to make things happen. Also, the technology behind the ideas. I personally focus more on hardware than software, I like tangible products, but all of these ideas are interesting. I also like the ‘drive’ for starting from scratch and setting up something completely new.” - Question: What advice would you like to give to the individuals here in the competition?

CG: “In a very short answer, HAVE FUN, even if it’s hard.” Visit this link for information on the winners of the competition: http://www.jeccomposites.com/about-jec/press-releases/the-3-winners-of-startup-booster-2018?utm_source=jec&utm_medium=whats-new&utm_campaign=jw18-startup-booster-winners.

Schmidt & Heinzmann (Bruchsal, Germany), founded in 1949 and known for its sheet molding compound (SMC) machines and expertise, had numerous announcements for showgoers, including news of the installation of what it claims is the most modern machine available for SMC manufacture. The production line can produce different SMC products by accessing various resin systems, and combining them with various fiber types; the state-of-the-art manufacturing machine is about to be commissioned within the next month. Also announced was a completely automated preforming process machine for production of composite leaf springs, delivered to a Germany technology research center. Schmidt & Heinzmann also revealed that it has developed a fully-automated bonding machine for producing composite automotive parts at Euro Advanced Carbon Fiber Composites (EACC, Esslingen am Neckar, Germany), a Toray subsidiary, who is using the machine to bond auto trunk lids: “We are pursuing a cycle time of under 15 minutes for all of our five trunk lid versions, with an assembly precision in the tenths of a millimeter range,” says Stephan Roßner, vice president at EACC for Development, Production and Quality.

Stratasys Inc. (Eden Prairie, MN, US) gave an overview of its many 3D printing initiatives, and a look at its latest machine, the fully-automated Fortus 900 machine for aircraft interior parts. The company has worked with the National Institute for Aviation Research (NIAR, Wichita, KS, US) on development of material standards and allowables for Ultem 9085 resin material (manufactured by SABIC, Riyadh, Saudi Arabia). The company says that new materials are coming in 2018 with lower coefficient to thermal expansion (CTE) and that its new trademarked carbon fiber material, Nylon 12CF, is now available for a range of Stratasys machines; the discontinuous carbon fibers are ~1 mm long, and make up 35% by weight of the compound.

TxV Aero Composites (Bristol, RI, US) is a 2017 joint venture between Tri-Mack Plastics Mfg. Corp. (Bristol, RI, US) and Victrex (Cleveleys, Lancashire, UK and West Conshohocken, PA, US), which combines Tri-Mack’s experience in high-temperature thermoplastic composite parts manufacturing with Victrex’s legacy of thermoplastic polyketone (PAEK) solutions. The intent is to offer a range of PAEK composites, from custom laminates to pre-formed composite inserts for hybrid molding processes, as well as design services, finished composite parts and complete over-molded hybrid composite components and assemblies, to aerospace. These innovative products can deliver weight savings of up to 60% over conventional metallic solutions and offer continuous manufacturing processes and cycle times measured in minutes versus hours for thermoset alternatives. Says CEO Jonathan Sourkes, “OEMs and Tier 1s are our target customers. With these materials and our molding methods, you achieve a very good buy to fly ration, virtually no waste, and reduced installation time and costs.”

Zünd Systemtechnik AG’s (Altstätten, Switzerland) large stand featured a new D3-L3200 double-beam automated cutting machine, which the company says doubles a customer’s productivity. Cut pieces are detected with a camera system that can be combined with a laser to highlight pieces for pick and place/kitting. The company emphasized that its systems are adaptable, flexible and Industry 4.0-ready, able to fit into existing customer manufacturing setups and automated work cells; its machine software is all open source, and can readily accommodate customer robotics. Zünd systems are known for speed, efficiency and ability to cut any material, including thermoplastic sheet and honeycomb cores, says the company.

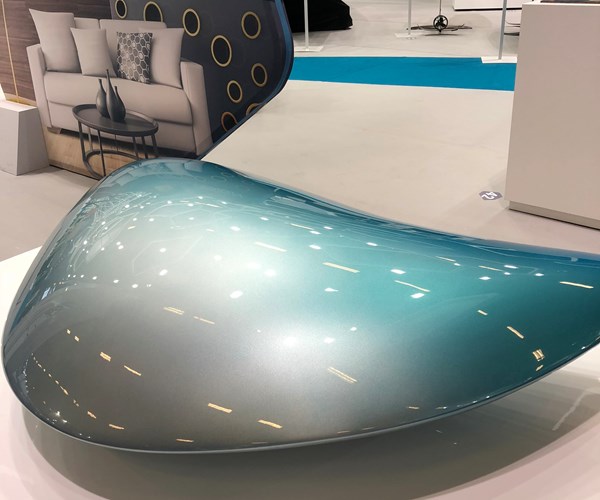

Composites can be art, too. CW was invited to meet Turkish sculptor Bülent Sancar, who exhibited an art piece in the “Make it Real” Planet area. The doubly-curved “Spazio Blu” (Blue Space) form (pictured) is part of Sancar’s Atlantis collection. All of the materials and a work space were provided by METYX Composites (Manisa, Turkey). Sancar shaped two complex, curved, elliptical plugs from polystyrene block, then built up a laminate with polyester resin and several layers of METYX’s multiaxial E-glass fabric, building up a sufficient laminate wall thickness to provide rigidity. He then wet-sanded the piece to a very smooth surface finish prior to priming the outer surface and applying acrylic paint to create the desired color and highly lustrous surface finish. Sancar says, “I knew as soon as I discovered composites that this was the right medium for me.” Read more about Sancar here: https://www.itsliquid.com/interview-s-bulent-sancar.html.

Web Industries (Marlborough, MA, US) announced at JEC World that it has changed the name of its Advanced Composites division to Aerospace division. The announcement was made by Web Industries vice president corporate development Kevin Young: “By renaming our composites division Aerospace, we are giving the marketplace a clear message and expectation of how we are dedicated to serving it.” The name change follows Web Industries’ 2017 launch of its Thermoplastic Composite Development and Qualification Center in Atlanta and complements the company’s latest aerospace product development, the new SpoolKit logistics solution. The SpoolKit consolidates formatted composites in a single container in the order with which they will be used by aerospace OEM customers. Web also reports that its Aerospace division has earned official accreditation from Nadcap (National Aerospace and Defense Contractors Accreditation Program) covering its aerospace-related composite ply cutting and kitting operations. The official certification is Nadcap AC 7118 Rev E ply cutting and kitting. It covers Web’s production facilities in Suwanee, GA, US. Finally, Web opened its first European sales office in Hamburg, Germany. The office will serve as a hub for making Web Industries’ full range of aerospace-focused composite formatting services available to the European market.

CoreLite (Acquanegra, Italy) unveiled the next generation of its PC11 Pro coating system, engineered to reduce resin uptake during the lamination process by sealing pores in end-grain balsa wood sheet more effectively than the company’s standard PC11 coating system. A typical balsa sheet of non-coated balsa wood core absorbs about 1900 g/m2 of resin during infusion. The company’s standard PC11 formulation reduced resin uptake by up to 46% to 1020 g/m2 of resin uptake. The new PC11 Pro formulation further reduces resin uptake by up to 76% to 450 g/m2.

2019 GMC Sierra Denali carbon fiber truck bed.

Continental Structural Plastics (CSP) confirmed that is is the manufacturer of the carbon fiber composite pickup bed for the 2019 GMC Sierra Denali. CSP manufactures the beds at its facility in Huntington, IN, US. CSP would not confirm the process used to make the beds, but did confirm that the material is discontinuous carbon fiber and the resin matrix is nylon. It is known, however, that GM and Teijin (which owns CSP) had worked for several years on development of Teijin’s Sereebo process, which features chopped carbon fiber combined with nylon using compression molding. Given this, it is likely the GMC bed is made via Sereebo. The application marks a significant and noteworthy advancement in the application of composites in high-volume automotive manufacturing.

SABIC, Airborne International and Siemens revealed that they have worked together to develop a preconsolidated carbon fiber/polycarbonate laminate product called UDMAX. It’s made in a fully automated process developed by Airborne that orients pre-cut unidirectional carbon fiber tapes in 0° or 90° orientations using plies dropped into conveyorized trays, which pass under drop zones as frequently as desired to build the ply stack. The manufacutring system at Airborne, controlled by Siemens, is expected to go live in early 2019. SABIC will sell laminates.

Huntsman Advanced Materials reported at JEC 2018 that it has acquired nanomaterials specialist Nanocomp, based in New Hampshire, US. Nanocomp is best know for its Miralon sheet and tape products, fabricated with nonwoven carbon fiber nanotubes. Sheets can be up to 8 ft long and 54 inches wide, and can be slit. Tapes can be up to 1000 ft long. Miralon offers a ver low CTE, high conductivity, high in-plane thermal conductivity and low through-plane themal conductivity. Under Huntsman ownership, said company officials, Miralon production capacity will be gradually increased, as will applications of the material. The Nanocomp name will eventually disappear. Miralon will become a brand within the Huntsman product line.

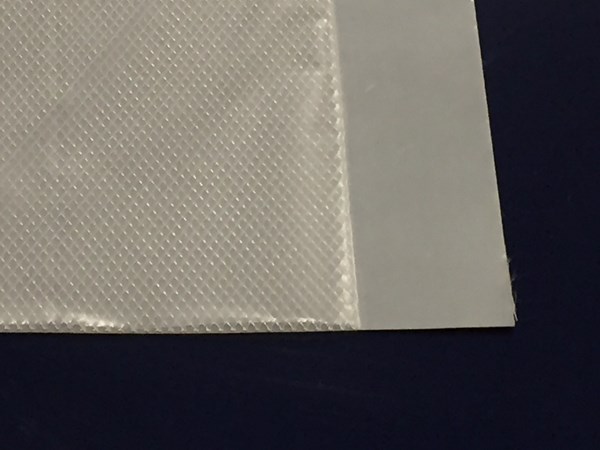

Solvay’s VAC-PLY VMS3.

Solvay had on its stand a trial carbon fiber/epoxy floor beam developed for the 777X using material it developed. CYCOM EP2150 prepreg will be used by a Mubadala Development Co./Solvay joint venture to fabricate 777X empennage and floor beams. This part and project are notable because Solvay developed CYCOM EP2150 as a functional equivalent of the Toray 3900 prepreg Boeing is using to fabricate the wing skins, wing spar, ribs and wing box for the 777X. Carbon fiber prepregs are, typically, developed to have unique properties, thus it required some effort and time for Solvay to create its own prepreg that so closely matched Toray’s. This would appear to signal to Boeing and Airbus that it is possible, on next-generation commercial aircraft, to have multiple carbon fiber suppliers produce prepreg to a given specification. It remains to be seen if aircraft OEMs pursue this strategy. Also of on the Solvay stand was a new product. VAC-PLY VMS3 is designed to maximize air removal during resin infusion processes, thus optimizing impregnation and avoiding dry spots. Benefits include reduced witness mark on the laminate surface, improved linear adhesive bond line reducing potential for resin penetration, thinner overall construction allowing for easier placement, and serial production capability.

A. Schulman’s (now LyondellBasell) Engineered Composites business announced the launch of a sheet molding compound (SMC) called LYTEX SF. This new epoxy-based, styrene-free material offers low out gassing and reduced volatile organic compound (VOC) emissions while maintaining a premium surface appearance for a high-end look and feel.

Related Content

Composite materials, design enable challenging Corvette exterior components

General Motors and partners Premix-Hadlock and Albar cite creative engineering and a move toward pigmented sheet molding compound (SMC) to produce cosmetic components that met strict thermal requirements.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreGraphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Read MoreMar-Bal expands SMC expertise through AltraSet materials division

The BMC company aims to fill the SMC market gap for those seeking optimal, low-volume demand with custom formulation and high material value.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More