Toray Advanced Composites BV

G. van der Muelenweg 2

Nijverdal, 7443 RE NL

31 548 633 933

explore@toraytac-europe.com

toraytac.com

About Toray Advanced Composites BV

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Toray Advanced Composites BV Supplies the Following Products

- Aramid

- Carbon

- Carbon fiber composite

- Chopped fiber

- Composite, other

- Continuous laminating

- E-Glass

- Expendable materials

- Fabric

- Laminate sheets, solid

- Mat

- Other thermoplastic prepregs

- Other tools/tooling supplies

- Prepreg

- Tape, unidirectional

- Tooling prepreg

Editorial, News, and Products

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

Toray Advanced Composites introduces Cetex PESU thermoplastic

Continuous fiber-reinforced thermoplastic composite targets full circularity in aircraft interior applications, with FST, impact resistance and toughness features.

-

People in composites: July 2024

New hires and position appointments have been announced across Dufour Aerospace, Toray Advanced Composites, FET, OSG USA, Lingrove and KraussMaffei.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

-

Fraunhofer IWS completes MFFD longitudinal fuselage joint using CONTIjoin technology

Thermoplastic composite upper and lower half shells for the Multifunctional Fuselage Demonstrator were welded using CO2 laser over a total length of 8 meters.

-

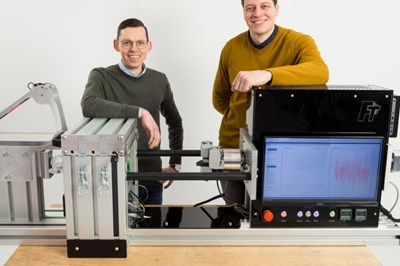

Thermoplastic tape friction tester completed at TPRC

Delivered and implemented at Toray Advanced Composites, the setup seeks to eliminate defects during hot press forming thermoplastic tapes.

-

Toray Advanced Composites launches LCA program for Cetex composites

Lifecycle assessment, starting at Toray’s Nijverdal site and then broadening to U.S. locations, will provide reliable emissions data to customers purchasing the range of thermoplastic composite materials.

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

-

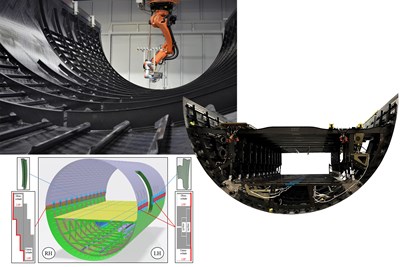

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Toray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

-

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

-

DLR completes MFFD upper shell skin layup

Eight-meter-long CFRTP fuselage skin was achieved via laser-heated in-situ consolidation, with stringers, frames and cleats to be welded.

-

ZeroAvia advances to certify ZA600 in 2025, launch ZA2000 with liquid hydrogen in 2027

Lightweight composite tanks are key to ZeroAvia’s vision for H2 aircraft to rival range and utility of jet fuel aviation.

-

Demonstrating composite LH2 tanks for commercial aircraft

Toray Advanced Composites and NLR discuss the Netherlands consortium and its 4-year project to build demonstrator liquid hydrogen tanks, focusing on thermoset and thermoplastic composites.

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

-

One-shot manufacture of 3D knitted hybrid thermoplastic composite structures

MAPICC 3D project replaces steel seat support in heavy-duty vehicle with a 3D knitted composite made from thermoplastic hybrid yarns comprising the matrix and reinforcing components.

-

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

-

People in Composites: April 2022

STRUCTeam, Toray Advanced Composites, Berndorf Band Group, North Technology Group, Beyond Gravity, Mighty Buildings and CoreTech Systems have announced new appointments for April 2022.

-

Will the Airbus-CFM H2 flight demonstrator use metal or composite tanks?

The Airbus A380 testbed will fly in 2026 with four 100-kilogram liquid hydrogen tanks — metal and composites are being developed via Airbus ZEROe Development Centres — with multiple other programs to develop composite H2 tanks for civil aviation that were begun in 2021.

-

Airborne participates in three technology development projects for new mobility solutions

Airborne will develop new digital and automated composites manufacturing technologies to advance maturation of UAM, civil aviation and automotive projects.

-

Toray Advanced Composites leads research consortium for LH2 composite tank developments

Dutch industries, institutes join Toray Advanced Composites for the manufacture of a civil aviation-focused lightweight composite tank which can withstand very low temperatures.

-

SAM|XL receives grant for composites research towards sustainable aviation

Jointly with TU Delft Faculty of Aerospace Engineering, the SAM|XL field lab will receive €4.9 million for projects in liquid hydrogen composite tanks, thermoplastic composite aerostructures and smart maintenance and repair.

-

DLR Institute of Structures and Design increases maturity of thermoplastic composite fuselage structures

Project with Airbus demonstrates OOA co-consolidated stringer-stiffened skin with resistance welded frame and cleats.

-

Automated aerocomposites production: Liquid molding or welded thermoplastic?

Two materials and process approaches are demonstrated for CFRP bulkhead production.

-

Recycled thermoplastic composite rotorcraft access panel takes flight

Designed as part of the TPC-Cycle program, the flight-tested panel demonstrates a lighter, cost-effective, sustainable thermoplastic composite application.

-

Proving out LMPAEK welding for Multifunctional Fuselage Demonstrator

Clean Sky 2 STUNNING project will manufacture lower thermoplastic fuselage while MECATESTERS will test LMPAEK in conduction and induction welding for parameters, cyclic loading, aging and environmental effects .

-

Recycled thermoplastic composites for production

Multi-year R&D at ThermoPlastic composites Applications Center (TPAC), TenCate and Clean Sky 2 demonstrate economic advantage of serial production using recycled materials.

-

Proving performance in EV powertrains

Simulation-driven development replaces aluminum with thermoplastic composites in gearbox housing.

-

TPAC and TPRC develop thermoplastic composites recycling process

Known as TPC-Cycle, the project targets production scrap by developing a recycling route for high-end and high volume markets.

-

New horizons in welding thermoplastic composites

Latest developments in qualification, production and applications for aerospace and automotive.

-

TenCate celebrates assembly of thermoplastic composite consortium in Brazil

The SPIRIT consortium seeks to collaborate and develop a regional knowledge-base in thermoplastic composite technology for the next generation of aircraft.

-

Toray acquires TenCate Advanced Composites

Toray, the world’s largest carbon fiber manufacturer, will pay €930 million for TenCate Advanced Composites to shore up its thermoplastic composites capabilities.

-

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

-

Thermoplastic composite wings on the horizon?

OUTCOME, a project under the Clean Sky 2 program, aims to industrialize out-of-autoclave thermoplastic primary aerostructure.

-

Materials & Processes: Fiber formats for composites

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

-

Plant Tour: Fokker Aerostructures: Hoogeveen, Netherlands

This Dutch aerospace supplier leverages its founder’s pioneering spirit from a century ago to lead the way, today, in thermoplastic aerocomposites.

-

Thermoplastic composites gain leading edge on the A380

Breakthrough manufacturing process produces lightweight, affordable glass-reinforced PPS J-nose on the worlds largest commercial aircraft wing.