Semipermeables: Next trend in infusion?

These liquid-blocking membranes promise molders better properties, less waste and reduced risk.

In conventional infusion processes, the vacuum system ideally draws resin in and draws air out to reduce the incidence of surface porosity and laminate voids. But despite the use of bleeders and breathers, evacuated air is inevitably accompanied by resin. This wastes resin, clogs vacuum lines and must be kept from damaging the vacuum pump through the use of catch pots. Vacuum lines must either be flushed with solvent or thrown away. In either case, processing cost is magnified. One promising solution is the semipermeable membrane (SPM), a thin, flexible film or fabric typically made from polytetrafluoroethylene (PTFE) or thermoplastic polyurethane (TPU). SPMs are permeable to gas but not to liquids.

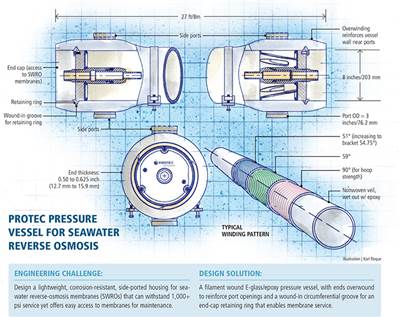

The use of an SPM is common in processes like reverse osmosis in water filtration (see, for example, "Designing pressure vessels for seawater desalination plants," under Editor's Picks," at upper right) and in the medical industry. A familiar example is Gore-Tex, a porous PTFE-based fabric produced by W.L. Gore & Associates (Newark, Del.), which is best known as the breathable but waterproof component of performance outerwear.

In the composites industry, SPMs are touted by proponents as potential pathways to easy, repeatable, high-quality infusion. Proponents variously suggest that SPMs be used as an additional layer in all or part of the materials stack or simply as a filtering cloth wrapped around the evacuation hose.

Membranes across the part

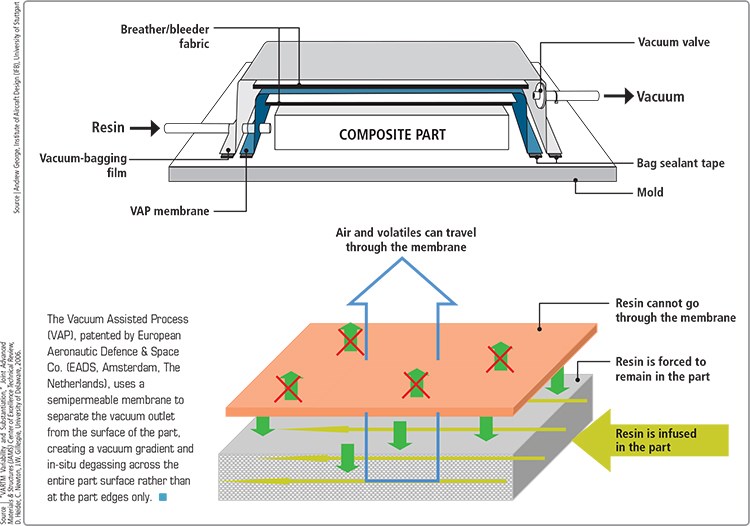

The Vacuum Assisted Process (VAP), patented by European Aeronautic Defence & Space Co. (EADS, Amsterdam, The Netherlands), is credited with significant improvement of infusion processes by using an SPM across the entire surface of the layup. Andrew George described it in his 2011 Doctor of Engineering Sciences (Dr.-Ing.) thesis for the Institute of Aircraft Design (or IFB), University of Stuttgart:

“VAP is a patented variation of resin infusion, where a semipermeable membrane separates the vacuum outlet from the surface of the part. This creates a full vacuum gradient and continued degassing across the part surface, as opposed to only at the end-edge of the part in traditional resin infusion. The full vacuum gradient theoretically results in fewer voids and reduced thickness gradients … thus higher mechanical properties and repeatability.”

George evaluated Gore-Tex and a variety of similar semipermeables from Saertex (Saerbeck, Germany), Pil Membranes (King’s Lynn, Norfolk, U.K.) and Airtech (Huntington Beach, Calif.). Other sources include Trans-Textil GmbH (Freilassing, Germany), now the licensed supplier of SPM products for EADS’ VAP method.

VAP proponents credit the use of an SPM with improving consistency in the flow front and removing dry spots without having to reduce vacuum. George noted that dry-spot removal during VAP is achieved without optimized vent placement. Citing University of Delaware research published in the 2004 Journal of Composite Materials article, “Process and Performance Evaluation of the Vacuum-Assisted Process,” George also observed that without any pre-infusion degassing, void content was reduced from 1.64 percent to a mere 0.37 percent, and thickness gradient was reduced 77 percent. However, he enumerated several disadvantages:

- Additional cost for the membrane — ~€15/m2 ($1.90/ft2) for PTFE and ~€5/m2 ($0.63/ft2) for polyurethane (TPU).

- Additional manufacturing steps (layup of the SPM and inspection to ensure that the SPM is wrinkle-free and situated appropriately within the stack).

- The risk of stretching the membrane during layup, which increases the pore size and, therefore, could reduce its ability to block liquids.

- Slower tool side flow vs. standard infusion (due to higher compaction from uniform vacuum across the entire part).

George also cautioned, “For a membrane to function correctly, it must not be saturated by the resin for the duration of the infusion to full cure. Certain membranes work with a particular set of process parameters, and do not work with others.” He concluded that wettability of the membrane is a critical parameter.

These concerns underscore the importance of modeling the process and performing actual tests — as infusion experts often recommend — to ensure desired resin flow when any new variables are introduced to an infusion setup (see “Aiming infusion at the application,” under "Editor's Picks," at top right). George’s testing showed the lowest void content when an SPM was used in conjunction with a distribution medium (DM). With a DM, PTFE gave a lower void content than TPU. PTFE, however, is much more expensive, so George maintained that TPU was worth considering but first should be tested in the particular infusion application.

By contrast, Jay Carpenter, a technical instructor at Abaris Training Resources (Reno, Nev.), has used semipermeables and found that they work well to address problematic flow areas. “We put the material on top of that area followed by a breather,” says Carpenter, “and it resolved the dry spot.”

“It makes sense,” he adds, “because now air can move out vertically, vs. having to be drawn out across the laminate from the vacuum inlet. It is an added step and expense, but it’s a relatively easy fix,” he notes. “A downside is that you can no longer see the flow because the semipermeable membrane isn’t transparent.”

Membrane-wrapped evacuation line

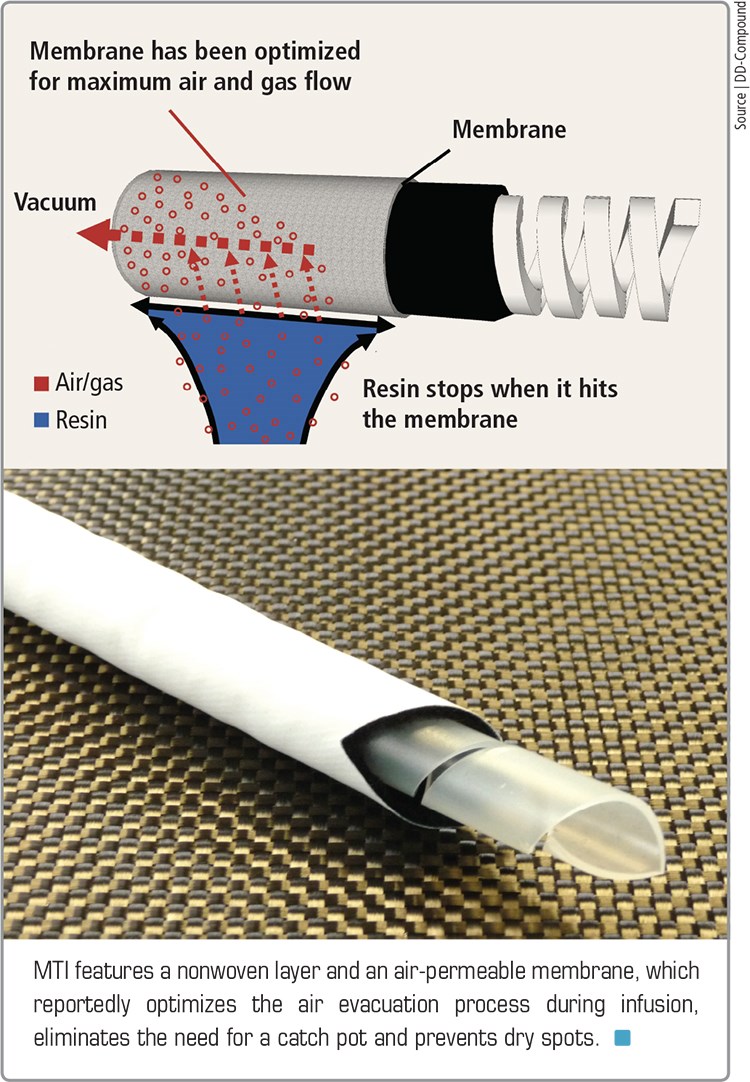

Significantly, George reports that VAP had its genesis in the use of PTFE merely to protect the vacuum port from resin intrusion. Introduced in 2011, Membrane Tube Infusion (MTI) hose is designed for that purpose. Described as an evacuation hose surrounded by a nonwoven layer and an air-permeable membrane, MTI, according to its proponents, also optimizes the air evacuation process during infusion. Developed and patented by DD-Compound (Ibbenbüren, Germany), and available in the U.S. via German Advanced Composites (Miami, Fla.), MTI eliminates the need for a catch pot and reduces resin consumption but reportedly also reduces dry spots and porosity.

“MTI hose can be used wherever spiral tubes or evacuation media have been used,” says developer Dominik Dierkes. When the hose is placed around the mold lip, resin reportedly stops when it reaches the membrane but continues to flow through the rest of the dry fabric, eliminating the need for complex calculations of resin injection points and ensuring complete wetout of the dry fabric.

When the Miss Geico offshore boat-racing team met Dierkes in October 2013 and agreed to give the MTI hose a try, team partner and crew chief Gary Stray admits, “I was very skeptical at first because, with composites, I have seen so many instances of ‘This is the next greatest thing.'” Because the team had been building its 50-ft/15.2m carbon fiber/epoxy catamarans using a standard vacuum-bagged wet layup process with postcure, Stray also had misgivings about a wholesale changeover to infusion.

“We had various material suppliers come in and tell us infusion was the way to go, but I was not 100 percent confident in it. You had to turn valves off and watch and control the resin flow the whole time in order to completely wet out the part with no dry spots,” he recalls. “It was not inherently easy nor repeatable.” Further, the boats are powered by twin 3,500-hp engines that weigh 1,500 lb/680.4 kg each. Capable of 200 mph/322 kmh in flat seas, they frequently face 4-ft/1.2m waves, enduring continuous 4G to 12G impact loads. There was, therefore, a lot of risk riding on the decision. “So we tested the MTI hose and infusion thoroughly,” says Stray, “making a ton of test panels and analyzing pure material specimens for properties.”

In the end, Stray and team were impressed: “With the MTI hose, the resin flow during infusion looks after itself,” he claims, explaining that “it moves until it hits the MTI line and then stops. If you have a dry patch, there is only one way for the resin to go, and the vacuum keeps pulling until the resin has permeated everything.”

That said, the team did not switch to infusion across the board but, instead, chose particular parts on the boat, including the structures where the engines are bolted in, the dashboards and the canopy. “All of these are critical parts,” says Stray, “but also benefit from superior properties and compacted laminates.”

For example, even though previous dashboards were built into the boat, they would vibrate and move when hitting a wave. “Now, using these infused structures, we haven’t seen or felt any movement,” says Stray, adding that analysis of cross-sectioned, finished laminates showed that “the parts we are pulling out have no air in them and no pinholes, where in the past we had to do a lot of post-cure finishing.” As a result, the team’s 2013 boats, after four months of racing, experienced no failures, and the team made plans to infuse an entire boat in early 2014.

Endorsed, with a caveat

Longtime infusion expert André Cocquyt (ACSM, Harpswell, Maine) agrees that MTI hose, in particular, “will pretty much eliminate resin-filled vacuum lines and the need for catch pots in many applications” and adds that “membranes are definitely going to become a major asset in our infusion toolbox.” However, he advises caution, lest molders duplicate processes that are covered, for example, by the EADS patent. “Users need to review existing patents to avoid violations,” he asserts, suggesting instead that they “use these materials as building blocks for [their own] process innovations.”

Related Content

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Aiming infusion at the application

With so many process variables to play with, how do you know which new solutions that promise better, faster infusion are right for your application?

Read MoreDesigning pressure vessels for seawater desalination plants

Safe high-pressure service challenges manufacturers of composite pressure vessels.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More