CW Blog

Structural adhesives, Part I: Industrial

Today’s myriad chemistry options enable formulators to tailor adhesives to customers' exact application requirements.

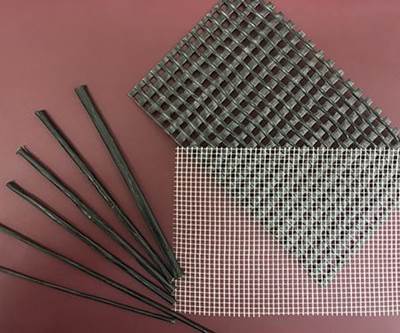

Read MoreSelective reinforcements boost “commodity” composite properties

Strategically placed advanced reinforcements reduce weight, cost while dramatically increasing mechanical performance and dimensional stability.

Read MoreComposites in exoskeletons

Wearable robotics need strength, stiffness and lightweight and are forecast at a CAGR of 40-50%. Will composites play a role or be left behind?

WatchCarbon fiber meets simulation in ultralight bike frame

Rolo Bikes wanted to design a bicycle frame with carbon fiber in mind, and it wanted test it in the virtual world.

Read MoreLarge portable antenna goes lightweight with conductive composites

CFRP matches metal performance at one-third the weight thanks to innovative materials and precision manufacturing.

Read MorePultrusions provide composite thermal break

Army hospital combats Alaskan cold with FRP shapes/fasteners.

Read MoreJEC World 2016: The final word

CW's editors have compiled all of their photos and observations from JEC World 2016. It's long, but a good read.

Read MoreGardner Business Index at 50.8 in February

New orders, production and future business expectations go up as small- and medium-sized fabricators see welcome expansion.

Read MoreNotched testing of composites

Open-hole test methods were developed in the early 1980s to compare toughness increases in new composite materials.

Read MoreCan we make recycled carbon fiber “sexy”?

Although we have methods to create useful product forms from recovered fiber, creating demand for those products will require new entrepreneurial effort.

Read MoreThe composites super cycle — are we still living the dream?

Predicted before the 2008 recessionary crash, the super cycle’s foundations were to be built on an increasing use of composites in aircraft. How did it play out?

Read MoreJEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

Read More