Hexagon Purus and CIMC Enric for construction of joint production facility and New Energy R&D management center

Investment agreements establish new facilities in China, aiming toward increased production capacity of hydrogen storage vessels.

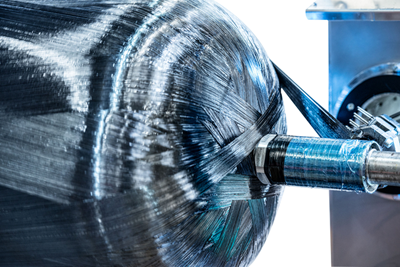

Read MoreHyPoint partners with GTL to extend zero-emission flight with ultralight liquid hydrogen tanks

NASA award-winning fuel cell pioneer works with carbon fiber tank maker GTL to offer up to 10 times more capacity versus existing hydrogen storage tanks.

Read MoreJoby Aviation advances toward FAA certification, highlights Toray prepreg and Coriolis AFP machines

Joby Aviation aims for FAA Part 135 certificate by end of 2022 and launch of commercial service by 2024 as it completes first production-intent aircraft from its pilot manufacturing facility; composites play a key role.

Read MorePlant tour: Qarbon Aerospace, Milledgeville, Ga. and Red Oak, Texas

Veteran aerostructures Tier 1 transforms into 21st century leader in thermoplastic composites and multiple new markets.

WatchLaboratory for Intelligent Lightweight Production at CTC Stade advances digital solutions for industrial composites

Four-year, 12-million-euro LaiLa project with Helmut Schmidt University combines R&D with industry collaboration to solve real production pain points, validate solutions in digital lab/model factory at CTC and transfer knowledge to supply chain including customized training.

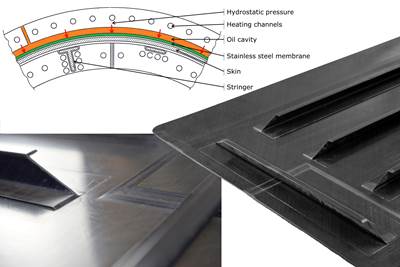

Read MoreHydrostatic membrane consolidation: Skin-stringer panels in 60 minutes

Airbus and Siempelkamp demonstrate press process as alternative to thermoplastic welding, aimed to enable rate 100 aircraft and future mobility manufacturing.

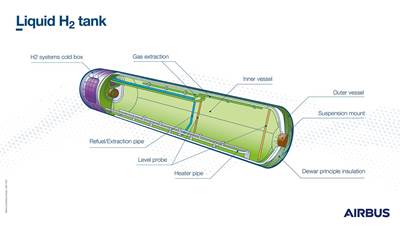

Read MoreWill the Airbus-CFM H2 flight demonstrator use metal or composite tanks?

The Airbus A380 testbed will fly in 2026 with four 100-kilogram liquid hydrogen tanks — metal and composites are being developed via Airbus ZEROe Development Centres — with multiple other programs to develop composite H2 tanks for civil aviation that were begun in 2021.

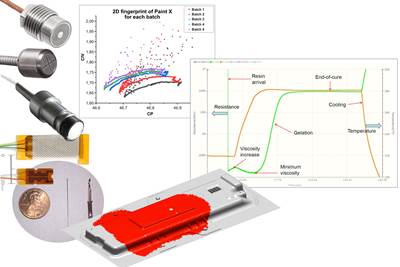

WatchSensors: Data for next-gen composites manufacturing

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

WatchPlant tour: Victrex Composites Solutions, Bristol, Rhode Island, U.S.

De-risking thermoplastic composites at industrial scale via hybrid overmolding.

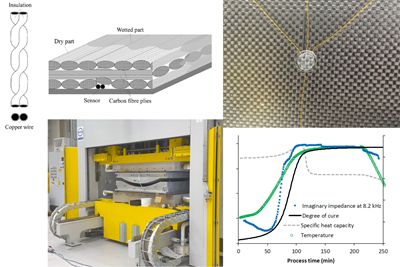

WatchNational Composites Center and Meggitt demonstrate linear dielectric sensor for liquid composites processing

Research at Cranfield University is further developed via RTM part trials in NCC’s Technology Pull-Through Program

Read MoreMulti-composite thrust chamber aims to boost rockets, reduce cost for New Space economy

Black Engine uses new, microporous CMC liner for transpiration cooling and multiple lightweight composites in modular design that offers increased lifetime and lower maintenance versus current launch vehicle engines.

WatchAirbus seeks 6,000 new hires in first part of 2022

Worldwide search focuses on new skills to support long-term projects and ambition, notably in the fields of decarbonization, digital transformation and cyber technology, with one-third of recruitment allotted to new graduates.

Read More