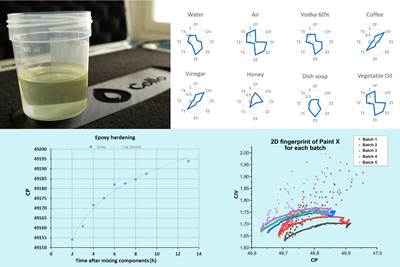

Fingerprinting liquids for composites

Collo uses electromagnetic sensors and edge analytics to optimize resin degassing, mixing, infusion, polymerization and cure as well as monitoring drift from benchmarked process parameters and enabling in-situ process control.

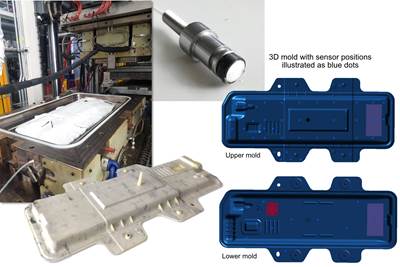

WatchCustomizing ultrasonic sensors for composites process optimization and control

University of Augsburg developed sensors for the CosiMo project’s digital twin and closed-loop process control of EV battery box cover demonstrator, and now moves forward with the AI Production Network for industry collaboration.

Read MoreSAM|XL receives grant for composites research towards sustainable aviation

Jointly with TU Delft Faculty of Aerospace Engineering, the SAM|XL field lab will receive €4.9 million for projects in liquid hydrogen composite tanks, thermoplastic composite aerostructures and smart maintenance and repair.

Read MoreEU launches Clean Aviation partnership, targeting 75% of civil fleet replaced for zero emissions by 2050

Clean Aviation carries forward from Clean Sky to develop disruptive new technologies, flight demonstrated by 2029 for aircraft into service by 2035 and aviation climate neutrality by 2050.

Read MoreFACC emphasizes fast-cure prepregs, thermoplastics, bio-based composites for next-gen aerostructure sustainability

The Tier One’s Sept. 2021 BEyond magazine highlights its investments in new factories, materials and technologies for the next generation of cost-effective, sustainable composites for aviation.

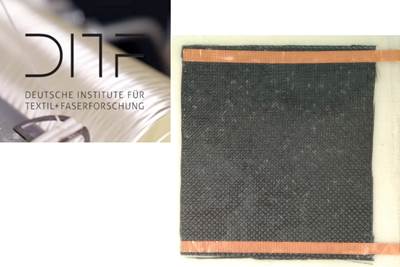

Read MoreDITF develops textile sensors for composites

German Institutes of Textile and Fiber Research are advancing large-area sensors that can detect deformations and stress using printing onto textiles which are then incorporated into composite structures.

Read MoreFraunhofer IPT develops thermoplastic composites in hydrogen storage, engine blades and more

Active in laser-assisted tape winding and in-situ consolidation of thermoplastic composites since 1988, the IPT in Aachen, Germany continues to push new materials, applications and Composites 4.0 digital processing.

WatchIn-situ composites sensors for increased production rates, smart processes and life cycle monitoring

Com&Sens FBG sensors are embedded into pressure vessels, rudders and bridges, with new edge and surface connection technology, aimed at cost-effective serial production and monitoring of composite structures.

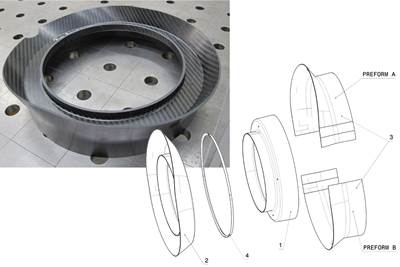

WatchComposite ring frame improves safety, cost for workhorse helicopter

Airbus Helicopters replaces aluminum primary structure with CFRP using multi-piece preform and single-shot infusion.

Read MoreReport forecasts record U.S. wind turbine installations for 2022

Demand for carbon fiber increases as decarbonization pushes transition to larger turbines, increased offshore market share more quickly than expected.

Read MoreAviation Week survey shows airlines want Boeing to develop modern 757 replacement

Need for long-hauler with up to 250 seats and 20% cost reduction could open door for composites. Boeing is already preparing via new digital engineering chief and integrated product team.

Read MoreAirbus foresees demand for 39,000 new passenger, freighter aircraft by 2040

Retirement of older aircraft to accelerate demand will be progressively driven by replacement, supporting the industry’s decarbonization objectives.

Watch